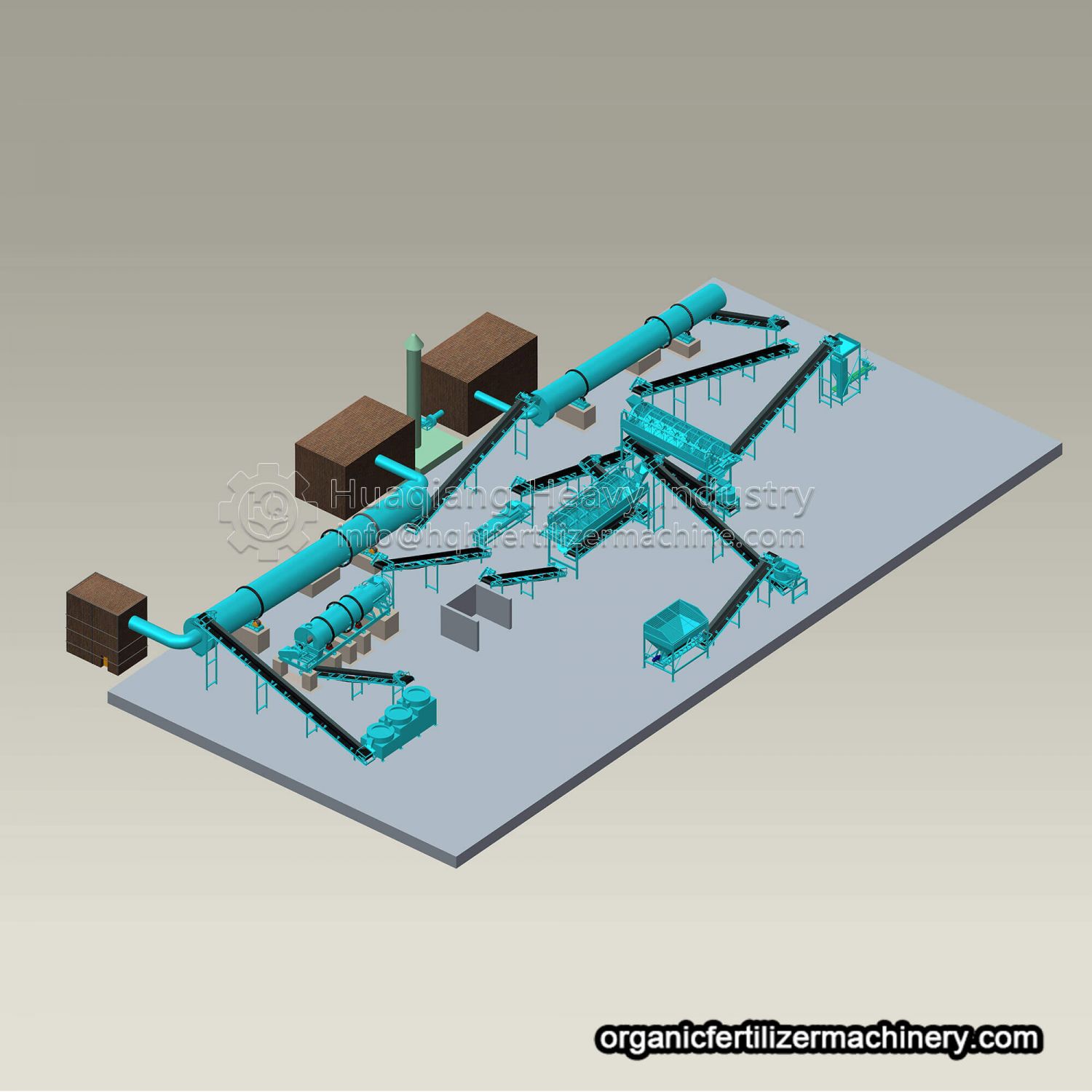

Fertilizer granulator machine is to be designed and used to produce the organic fertilizer granulator or compound fertilizer granulator.In the fertilizer manufacturing process,it is to be designed and equipped in the fertilizer manufacturing process to finish the granulation process.

In organic fertilizer production line,it is to be equipped with different type and series fertilizer machine to finish the production process.The fertilizer granulation machine has important features of organic fertilizer granulator:

1.The particles produced are apherical;

2.The content of organic matter can be as high as to realize the granulation of pure organic matter;

3.The organic particles can be embedded with each other under a certain force,so there is no need to add binder during granulation.

4.The particles are solid and can be screened after granulation to reduce the engery consumption of drying.

5.The organics after fermentation do not need to be dried,and the moisture content of raw materials can be 20-40%

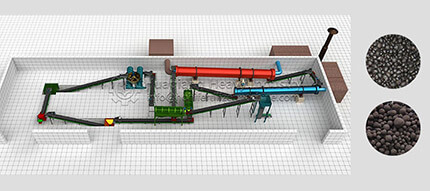

And the flat die granulator machine is usually to be used in biofertilizer production line to finish the granulation process.In the bio organic fertilizer production,how to work of the flat die granulator machine.The screened raw materials are fed into the flat die granulator evenly,and the cylinndrical particles are extruded under the extrusion of the die. After extrusion and granulation,the organic fertilizer particles have moderate hardness and neat shape.The particles enter into the thrower,and rotate and rub with the inner wall of the thrower.The shape is smooth,the size is even,and it is easy to use.The temperature of flat die granulator is low in the process of processing,and it can be better maintain the internal nutrients of raw materials.After particle forming,drying and cooling steps can be omitted,and finishing can be continued. After drying, cooling, screening, packaging and storage.

The flat die granulator is simple in operation and low in energy consumption. The pelletilizing production line of flat die organic fertilizer integrates fermentation and processing, with mature technology and high value of commerical organic fertilizer. Organic fertilizer products not only provide comprehensive nutrition for crops,but also have long fertilizer effect, which can increase soil organic matter and promote microbial reproduction.

The fertilizer granulation process, which using the fertilizer equipment to finish the production process is more simple and easier to be operated. At the same time,the using of the fertilizer equipment also improve the working efficient of the fertilizer production process.

.jpg)