In the fields of fertilizer production and industrial manufacturing, disc granulators have become key equipment for producing high-quality spherical particles through their unique rolling granulation technology. This traditional yet efficient granulation method transforms powdered raw materials into uniform spherical particles through clever mechanical design, widely applied across multiple industries including fertilizer, metallurgy, and building materials.

Innovative Working Principle

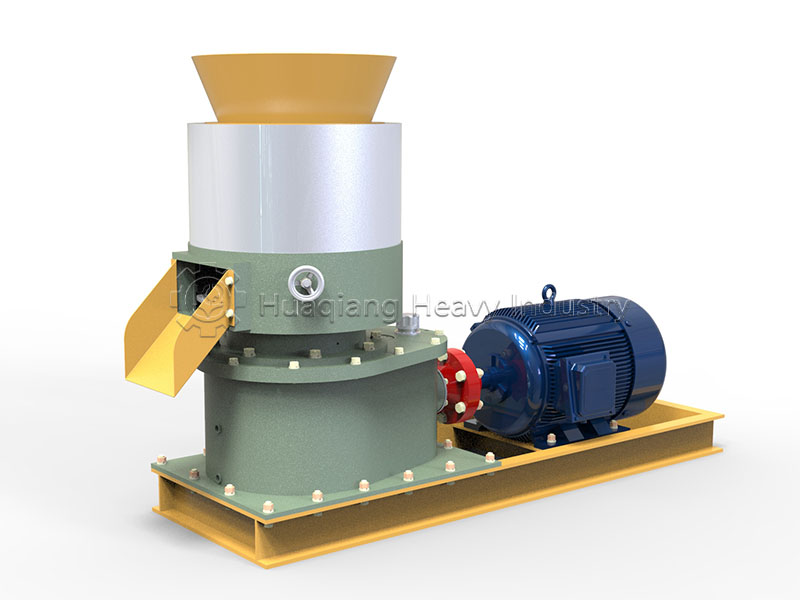

The core working principle of disc granulators is based on synergistic effects of centrifugal force, friction, and gravity. When the inclined disc rotates at 5-30 revolutions per minute, materials roll and collide along specific trajectories within the disc. By spraying appropriate amounts of water or binders, powdered materials gradually adhere to form small particles, which then absorb more materials during continuous rolling, eventually forming regular spherical particles.

The ingenuity of the equipment lies in its adjustability. The disc’s inclination angle can be adjusted between 30°-60°, while rotation speed can also be regulated as needed, enabling the equipment to adapt to characteristics of different materials. This flexibility allows disc granulators to produce particles with sphericity exceeding 85%, providing great convenience for subsequent storage, transportation, and usage.

Wide Range of Application Fields

Disc granulators play important roles in multiple industries. In fertilizer production, they are particularly suitable for manufacturing organic and compound fertilizers. Spherical particles are not only aesthetically pleasing but, more importantly, possess good flowability and uniformity, facilitating mechanized and precise fertilization. In metallurgical industries, the equipment can transform mineral powders into particles suitable for sintering and smelting.

The building materials and chemical industries also represent important application fields for disc granulators. From cement raw materials to catalysts, from refractory materials to pigment particles, this equipment provides efficient production solutions. Differences in requirements across industries can be met by adjusting equipment parameters and using lining materials of different compositions.

Efficient Production Process

The production process of disc granulators is meticulously designed to ensure high efficiency and quality. Production begins with raw material pretreatment, including crushing, mixing, and moisture adjustment. Materials are then uniformly fed into the rotating disc while appropriate amounts of water are added through precisely controlled spraying systems.

During pellet formation, controlling material moisture content between 10%-20% is crucial. Excessive moisture causes particle agglomeration, while insufficient moisture makes formation difficult. Operators observe particle formation conditions in real-time, adjusting disc angle, rotation speed, and water spray volume to ensure optimal pelletization results. Granulated particles undergo screening and post-processing, ultimately becoming qualified finished products.

Significant Technical Advantages

Disc granulators possess multiple technical advantages. Firstly, the spherical particles produced have excellent flowability, facilitating mechanized operations. Secondly, the equipment structure is relatively simple, with both operation and maintenance being relatively easy, lowering usage thresholds. Thirdly, the equipment demonstrates strong adaptability to raw materials, capable of processing various material types.

Regarding economic benefits, disc granulators also demonstrate excellent performance. Equipment investment is relatively low with controllable maintenance costs, suitable for enterprises of different scales. Production efficiency is high, with single units capable of producing 1-20 tons of particles per hour, meeting large-scale production demands.

Scientific Maintenance Management

To ensure long-term stable equipment operation, scientific maintenance management is crucial. Daily maintenance includes equipment checks before startup, condition monitoring during operation, and cleaning work after shutdown. Regular inspection of wear part conditions and timely replacement of worn components are key to maintaining equipment performance.

With continuous technological development, disc granulators are also constantly innovating and improving. New material applications extend equipment lifespan, while introduction of intelligent control systems improves production efficiency. In today’s global pursuit of sustainable development and efficient production, disc granulators will continue playing important roles in particle production across various industries, providing reliable technical support for industrial production and agricultural development.

Integrating Disc Granulation into Comprehensive Fertilizer Manufacturing Systems

The disc granulator, a core machine for disc granulator for shaping spherical particles, plays a specific role within the broader spectrum of fertilizer granulation processes. In a complete npk fertilizer production line, powder prepared by a npk blending machine is often granulated using such equipment. The disc granulator machine is central to a disc granulation production line, which is one type of fertilizer granulator system suited for materials requiring high sphericity.

For organic fertilizers, the production chain is different. It often begins with a windrow composting machine for biodegradation before the material enters a separate organic fertilizer production line or a bio organic fertilizer production line. Here, the disc granulator may also be used, but alternative technologies like the double roller press granulator in a roller press granulator production line offer dry granulation options. This diversity in equipment—from disc granulators for wet forming to roller presses for dry compaction—highlights the sophistication of modern fertilizer granulation processes, allowing manufacturers to select the optimal technology, whether for an npk fertilizer line or an organic system, to produce high-quality, application-ready fertilizers efficiently.