The creation of bio-organic fertilizer is a vivid example of the resource utilization of organic waste. Its production line is like a sophisticated “transformation assembly line,” allowing livestock manure, crop straw, and other waste materials to undergo multiple processes, ultimately transforming them into high-quality fertilizers that nourish crops. Bio organic fertilizer production line not only carries an environmental mission but also embodies the technological wisdom of modern agriculture.

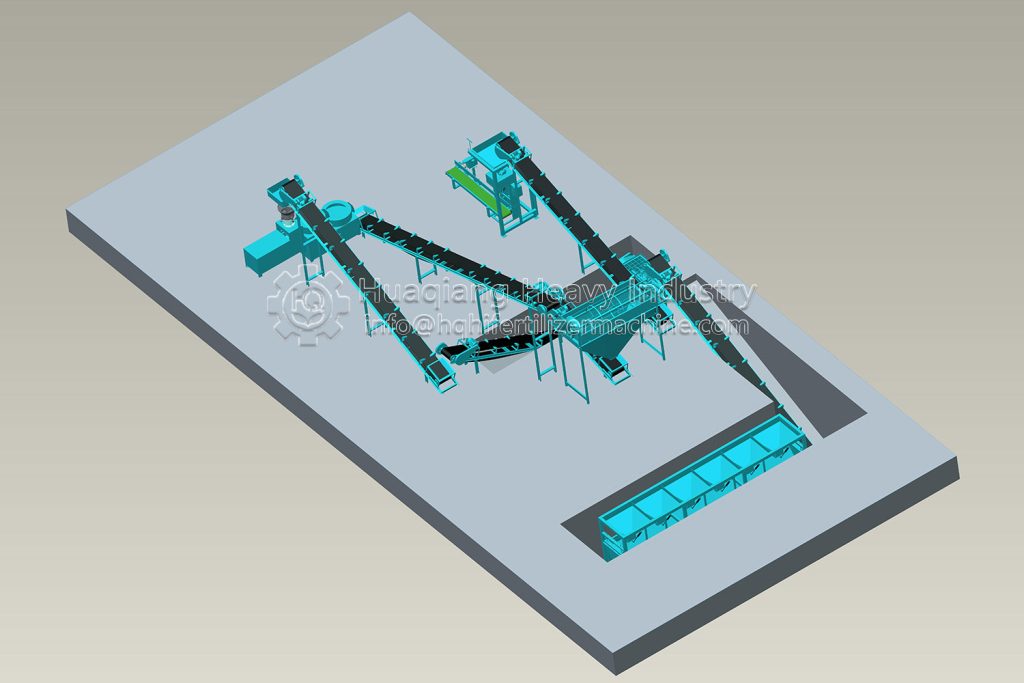

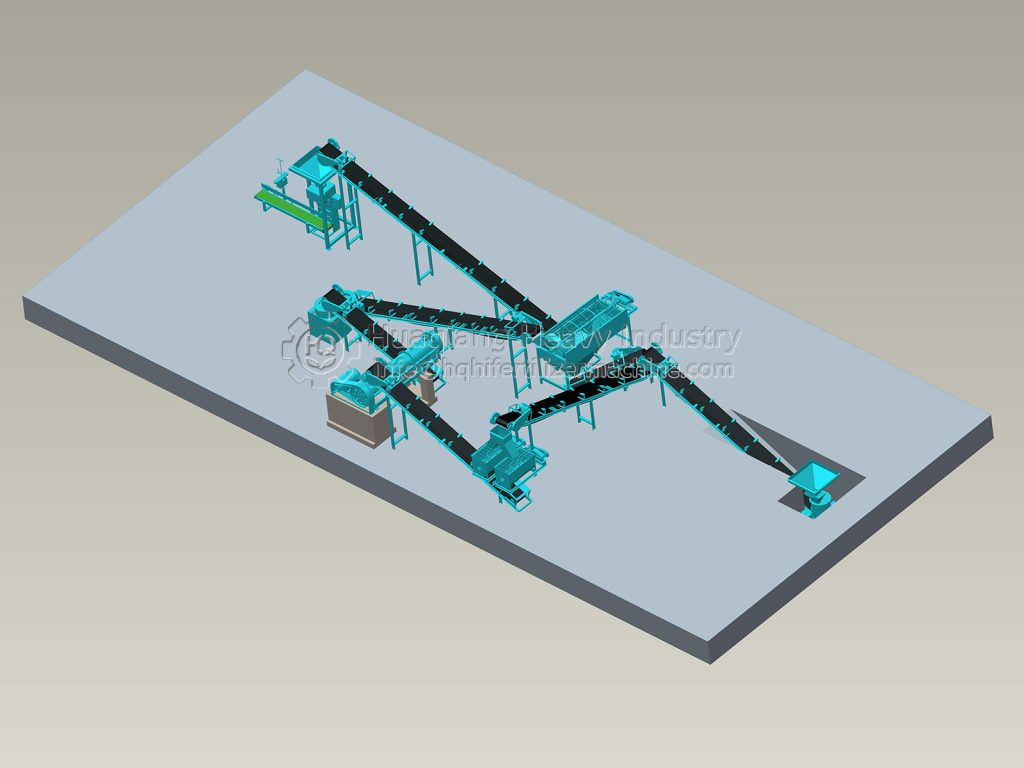

Raw material pretreatment is the first step in the production line and the fundamental guarantee of fertilizer quality. Workers first screen the raw materials, such as livestock manure, crop straw, and mushroom residue, to remove impurities like stones and plastics, preventing them from affecting subsequent processing. Then, a crusher is used to pulverize large raw materials like straw to a suitable particle size. The materials are then mixed in scientific proportions, while adjusting the moisture content and carbon-to-nitrogen ratio. This step is crucial; appropriate moisture and carbon-to-nitrogen ratios create optimal conditions for microbial fermentation, directly determining fermentation efficiency and fertilizer quality.

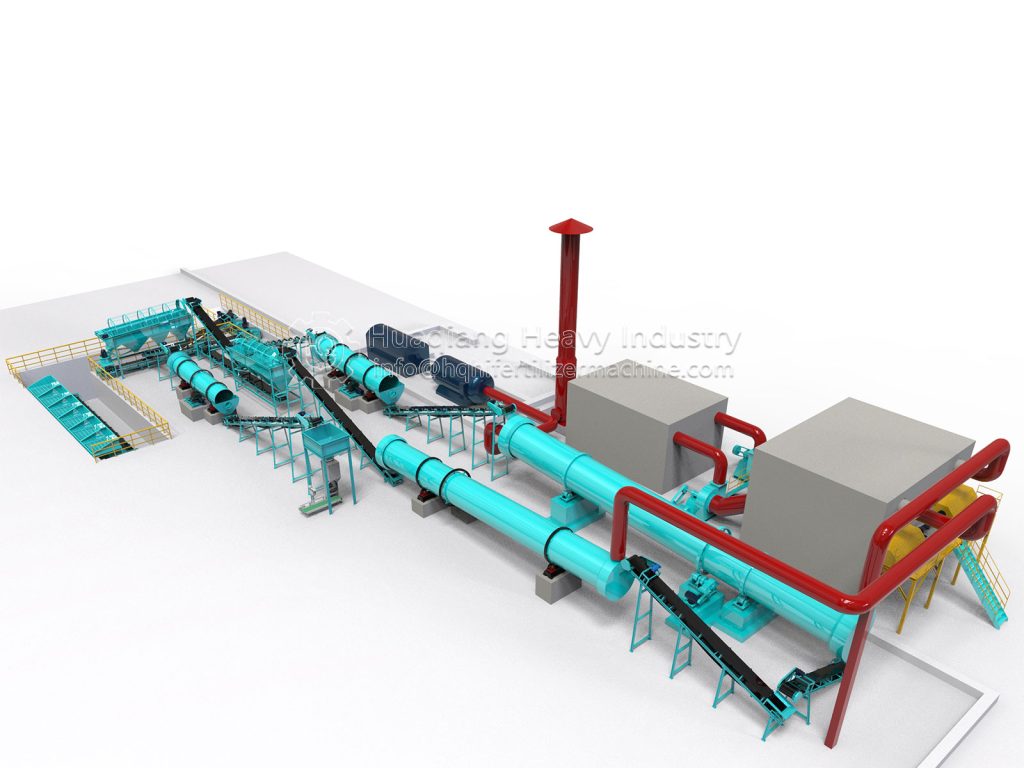

Fermentation and maturation are the core of bio-organic fertilizer production, the key to transforming waste into valuable resources. The uniformly mixed raw materials are sent to the fermentation tank, where specialized microbial agents are added, and a compost turning machine is used for regular turning. Turning not only provides sufficient oxygen for microorganisms but also regulates the fermentation temperature, keeping it between 55-65°C. This temperature range kills pathogens, insect eggs, and weed seeds in the raw materials while ensuring the activity of beneficial microorganisms. After 15-20 days of continuous fermentation, the raw materials gradually mature, turning dark brown, the original odor disappears, and a loose, mature material is formed.

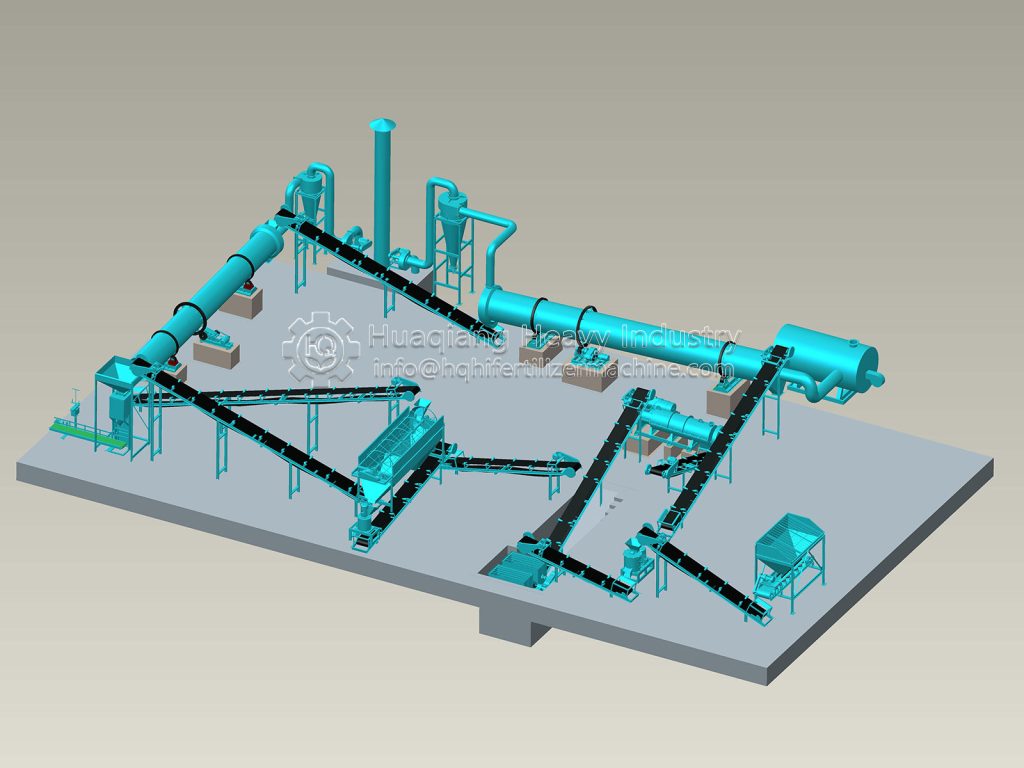

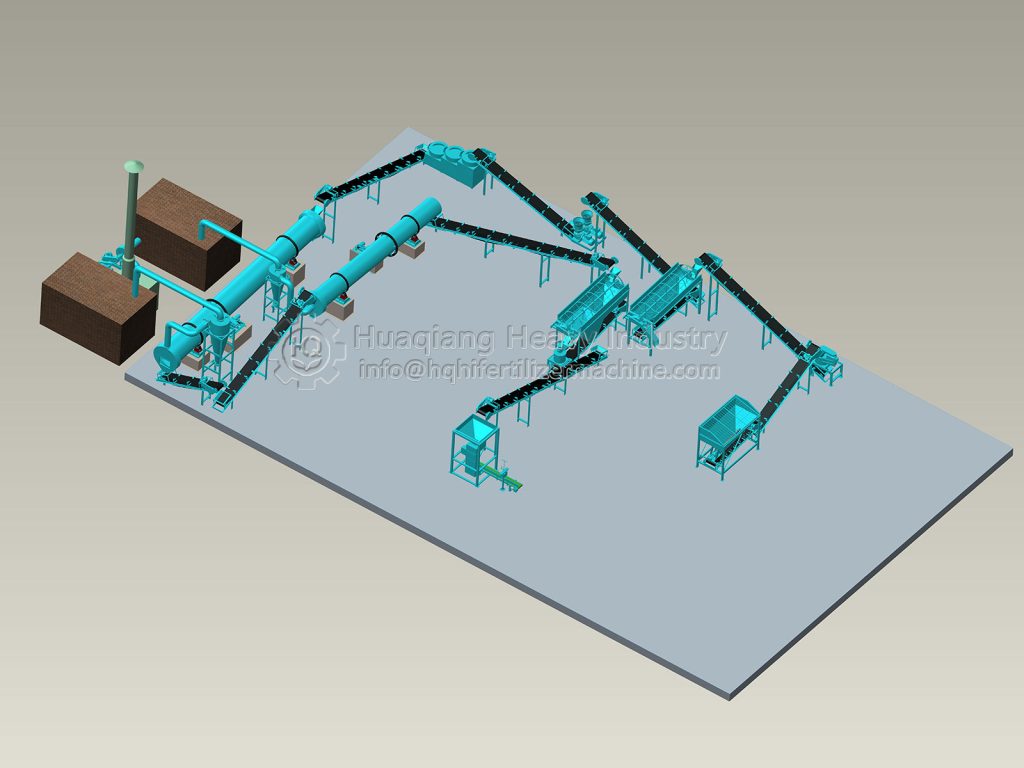

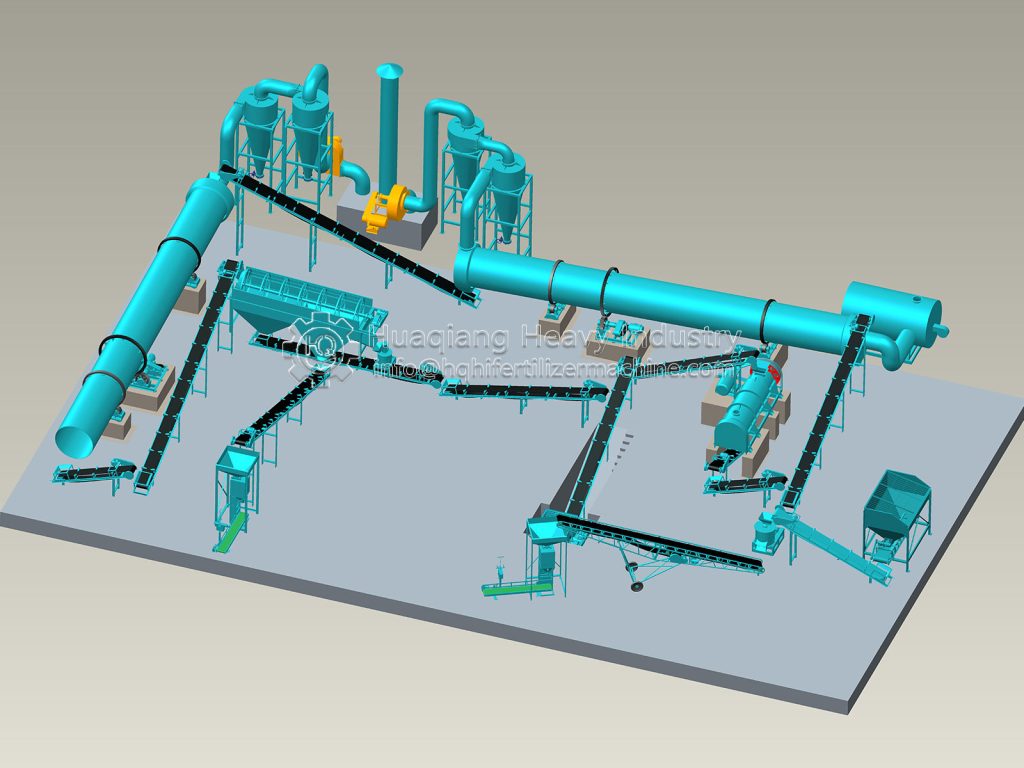

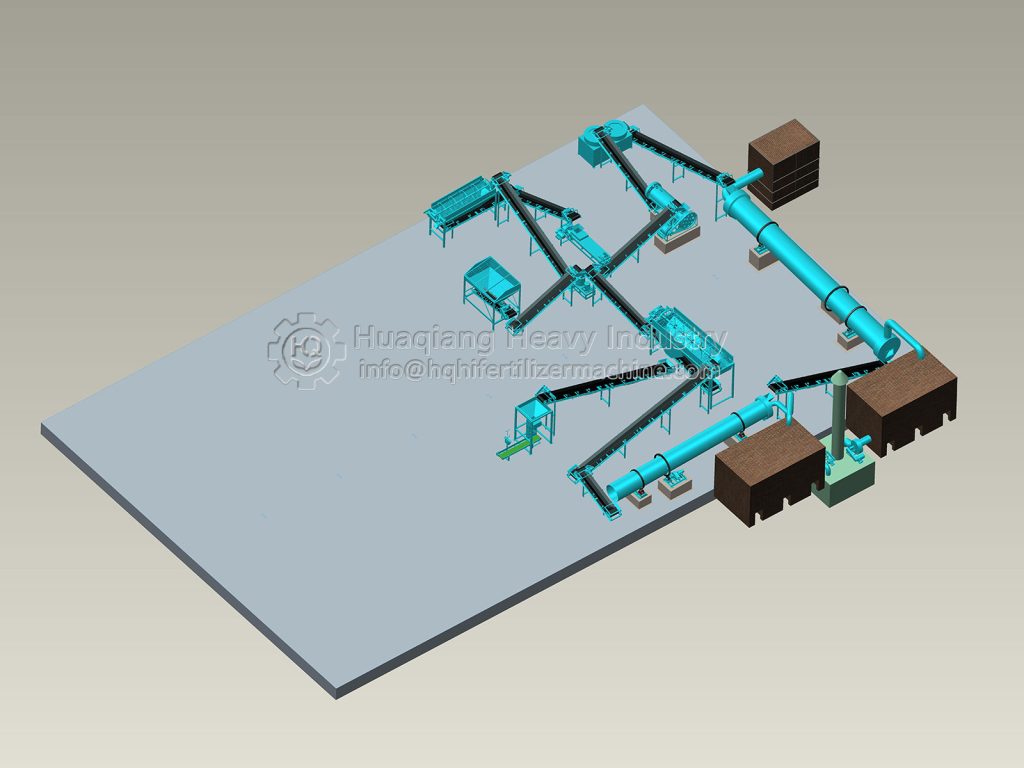

The matured material needs further processing to become a qualified finished product. First, it is screened using bio-organic fertilizer equipment such as a rotary screen to remove incompletely fermented large pieces of material, resulting in fine and uniform material. For products requiring granulation, the qualified material is sent to a fertilizer granulator machine, where, with the help of a binder, it forms granules of uniform size. Granulated organic fertilizer is easier to store and apply, making it more popular in the market. After granulation, the process moves to the drying and cooling stage. Excess moisture is removed using a dryer, followed by cooling to prevent the granules from clumping and deteriorating.

Finally, the finished product is packaged and inspected. The cooled organic fertilizer is screened again to ensure uniform granule size. It is then weighed and packaged by an automatic packaging machine, and product labels are applied, indicating nutrient content, production date, and other information. Before packaging, quality control personnel conduct sample testing to check indicators such as organic matter content, effective viable bacteria count, and heavy metal content. Only products that meet national standards are allowed to enter the market and be used in agricultural fields.

From organic waste to high-quality bio-organic fertilizer, every step of the production line is interconnected and meticulously executed. This “transformation journey” not only solves the problem of waste pollution but also achieves resource recycling, injecting continuous momentum into the development of green agriculture and contributing to the healthy cycle of the agricultural ecosystem.