For all plants, growth depends on two things: fertilizer and water. However, traditional agriculture faces a significant dilemma: a large portion of the applied chemical fertilizers is not absorbed by plants but is instead wasted into the environment. This not only represents a huge waste but also pollutes water and soil.

Today, a new type of “smart” fertilizer offers hope for solving this problem. It is like a carefully designed “nutrient capsule” that can intelligently control the release of nutrients and lock in moisture like a miniature reservoir.

The Dilemma of Traditional Fertilizers: Quick to Come, Quick to Go

Traditional chemical fertilizers, such as NPK compound fertilizers, dissolve rapidly. Once applied to the soil, a heavy rain or a few rounds of irrigation can wash away a large amount of nutrients. Statistics show that in ordinary fertilizers, 40%-70% of nitrogen, 80%-90% of phosphorus, and 50%-70% of potassium cannot be effectively used by crops and are directly lost.

This is like giving a thirsty person a large bucket of water; they only have time to take a few sips before most of it spills on the ground. It neither quenches thirst nor avoids waste and pollution.

Three-Layer Structure: An “Intelligent” Design with Distinct Roles

Inspired by “capsules” and “sponges,” scientists have designed a three-layer controlled-release and water-retaining composite fertilizer.

Core: The Nutrient Warehouse

The innermost part is a standard water-soluble NPK fertilizer granule, storing the core nutrients needed for plant growth.

Middle Layer: The Smart Valve (Chitosan Coating)

The core is wrapped in a layer of natural material called “chitosan,” derived from shrimp and crab shells, which is biodegradable. This membrane acts like an intelligent regulating valve, slowing down the dissolution rate of the inner fertilizer granule. It allows nutrients to be released slowly and continuously, synchronizing with the plant’s growth needs.

Outer layer: Micro-reservoirs (superabsorbent polymer)

The outermost layer is made of a superabsorbent polymer material that can absorb dozens or even hundreds of times its own weight in water. In the soil, it acts like countless tiny reservoirs, securely holding irrigation water or rainwater, reducing water evaporation and deep percolation. When the soil dries out, it slowly releases the water back to the plant roots.

Multiple Advantages in One

This three-layer “smart” fertilizer combines the dual benefits of slow-release fertilizer and water-retaining agent:

Saves Fertilizer: Slow nutrient release significantly improves utilization efficiency, reducing the amount and frequency of fertilization.

Saves Water: Powerful water retention reduces irrigation demands, making it particularly suitable for arid regions.

Environmentally Friendly: The coating materials (chitosan and polymer) can degrade naturally in the soil, reducing environmental pollution.

Promotes Growth: Stable supply of water and nutrients creates a better growing environment for plants.

Experiments show that this fertilizer can absorb 70 times its own weight in water within 90 minutes and exhibits excellent slow-release properties in the soil.

Green Agriculture for the Future

This three-layer “smart” fertilizer represents an important direction in agricultural technology: achieving higher yields with fewer resources while protecting our fragile environment. It is not only a “nutrient package” for plants but also a sustainable gift to the land.

Moving from the laboratory to the fields, such innovative technologies have the potential to help farmers worldwide address challenges like water scarcity and environmental pollution, paving new paths for ensuring food security and achieving green agriculture.

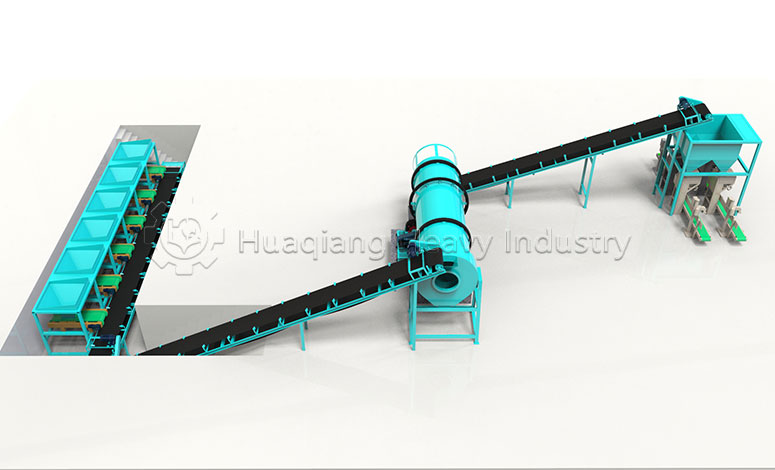

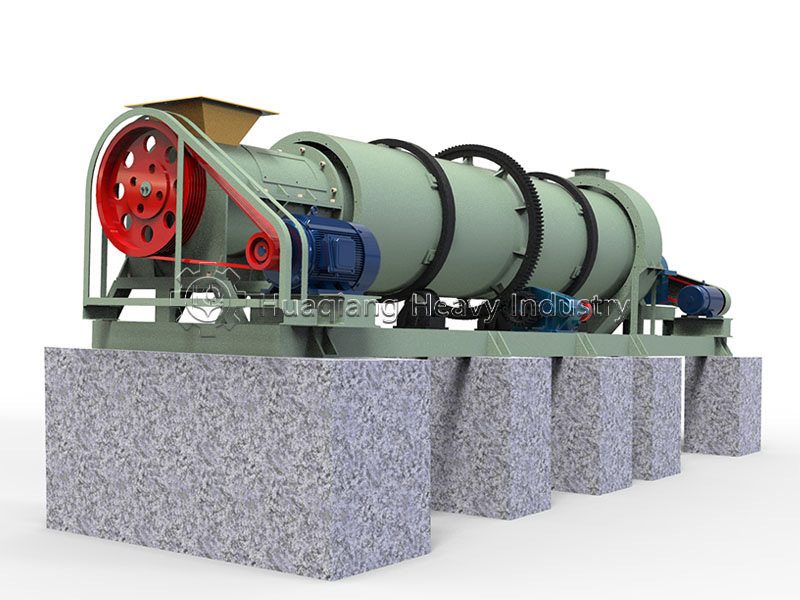

From Innovation to Industry: Manufacturing the Next Generation of Fertilizers

The creation of advanced “smart” fertilizers with controlled-release and water-retaining layers begins with a sophisticated industrial foundation. The core nutrient pellet is manufactured using established npk fertilizer production technology within a complete npk fertilizer production line. This process starts with precise formulation using a npk blending machine or a bulk blending fertilizer machine. The mixed powder then undergoes fertilizer granulation via advanced npk granulation machine technology, utilizing equipment like a npk fertilizer granulator machine or a fertilizer roller press machine.

The entire npk fertilizer manufacturing process, central to the manufacturing of npk fertilizer, must ensure the production of high-quality, uniform base granules before the advanced coating can be applied. Factors such as NPK compound fertilizer production capacity and NPK fertilizer production price are influenced by the efficiency of this core granulation stage and the integration of specialized npk fertilizer machine systems. The successful industrial-scale production of these innovative fertilizers demonstrates how cutting-edge material science must be seamlessly integrated with precision manufacturing processes to deliver sustainable agricultural solutions that enhance nutrient and water use efficiency on a global scale.