In modern industrial production processes, material drying technology plays a crucial role. Among these, drum drying, a classic drying method, has been widely used in various industries. This technology achieves rapid dehydration by evenly coating the material onto the surface of a heated rotating drum. However, behind this seemingly simple process lie complex technical details and application limitations.

Process Principles and Technical Flow

The core of drum drying lies in the clever combination of heat transfer and material movement. The entire process typically involves four continuous and precise steps, each of which significantly impacts the final product quality.

The feeding stage is fundamental to the success of the process. The wet material must be evenly coated onto the drum surface, with a thickness typically between 0.1 and 1.5 millimeters. A chemical company in Shanghai uses drum drying to process pigment slurry, and they ensure that the coating thickness error does not exceed ±0.05 millimeters through a precisely designed feeding device. This precision control is crucial for ensuring consistent product quality. Common feeding methods include immersion, spraying, and roller coating; the appropriate feeding method needs to be selected based on the material characteristics.

The design of the heating system directly affects drying efficiency. The drum is usually heated by steam, with the temperature controlled between 80 and 150 degrees Celsius. An engineer from a German equipment manufacturer explained that they use a double-shell design, with the inner layer serving as the heating medium channel and the outer layer as the material contact surface. This structure ensures uniform heat distribution. In actual operation, the heating temperature needs to be precisely adjusted according to the material characteristics and moisture content.

The evaporation process occurs during two-thirds of the drum’s rotation cycle. As the drum rotates slowly, the thin layer of material is gradually heated, and the moisture evaporates rapidly. Rotation speed control is a key parameter, usually maintained at 2-10 revolutions per minute. Too fast a speed can lead to insufficient drying, while too slow a speed may cause the material to overheat. A British food processing plant, when drying mashed potatoes, controls the rotation speed at 4.5 revolutions per minute, ensuring both effective drying and preventing starch denaturation.

The scraping stage requires extremely high precision. The scraper, installed at a specific angle, must remain sharp to ensure that the dried material is completely removed. A Japanese equipment manufacturing company has developed an automatically adjusting scraper system that can adjust the scraping angle and pressure in real time based on the roller surface condition, significantly improving product yield.

Technological Limitations and Challenges

Despite the maturity of roller drying technology, its inherent limitations restrict its application range. Heat-sensitive materials are particularly susceptible to damage, which is especially evident in the food and pharmaceutical industries. A French pharmaceutical company attempted to dry a certain antibiotic intermediate using roller drying, but found that the high temperature resulted in a 15% loss of active ingredients, ultimately forcing them to switch to vacuum drying technology.

Capacity limitations are another prominent issue. Compared to spray drying, the processing capacity per unit time of roller drying is significantly lower. A US dairy company conducted comparative tests and found that, under the same energy consumption, the capacity of spray drying was three times that of roller drying. This prompted them to upgrade most of their production lines to spray drying systems.

There are also significant limitations in material adaptability. High-sugar materials tend to stick to the roller surface and are difficult to scrape off. An Italian confectionery company attempted to dry caramel syrup using roller drying, but the product yield was less than 70%, with a large amount of material remaining on the roller surface. Similarly, materials containing salt or other corrosive components may damage the roller surface, shortening the equipment’s lifespan.

Equipment investment and maintenance costs are also factors to consider. Precisely machined rollers are expensive, and replacement costs are even higher. A Chinese chemical company calculated that the initial investment in a roller dryer was 30% higher than similar drying equipment, and the annual maintenance costs were also 15% higher.

Operational complexity cannot be ignored. Maintaining a stable film requires operators to have extensive experience and be able to balance multiple parameters such as feeding speed, roller rotation speed, and temperature. Novice operators typically require 3-6 months of training to become proficient.

Special Applications in Grain Processing

Roller drying has a rather unique application in the field of grain processing. Although technically feasible, there are significant limitations in practical application. For raw grains, the conditions of roller drying are too harsh. Experiments by a Canadian grain research institute showed that roller drying increased the cracking rate of wheat by 8% and increased the degree of protein denaturation by 12%, significantly reducing processing quality and storage stability.

However, in the processing of grain by-products, roller drying has found its niche. Materials such as flour, bran, and starch are particularly well-suited to this drying method. An Australian feed company uses drum drying to process wheat bran, controlling the drum temperature below 90 degrees Celsius to achieve effective drying while preserving nutrients. They have specifically improved the feeding system to ensure the wheat bran is evenly distributed on the drum surface.

Drying animal feed pellets is another suitable application. Drum drying can quickly remove surface moisture from the pellets while maintaining internal moisture content. A Danish feed factory uses drum drying to process fish feed pellets, precisely controlling the drying time to achieve the ideal moisture content while maintaining the integrity and nutritional value of the pellets.

Technological Development and Future Trends

Faced with the limitations of traditional drum drying technology, equipment manufacturers are actively seeking innovative solutions. New drum dryers employ a segmented heating design, with different temperatures set in different zones to adapt to the drying characteristics curve of the material. Intelligent control systems monitor material status in real time through sensors, automatically adjusting process parameters and reducing operational difficulty.

Advances in materials science have also brought new possibilities to drum drying technology. The application of special coating materials reduces material adhesion problems, and the development of corrosion-resistant materials expands the range of applicable materials. A ceramic-coated drum developed by a German engineering company has a lifespan twice as long as traditional stainless steel drums and also improves heat transfer efficiency.

With increasing environmental requirements, energy recovery systems have become a new development direction. The installation of waste heat recovery devices reduces the energy consumption of drum drying by 20-30%. A closed-loop drum drying system developed by a Japanese company not only recovers waste heat but also reduces dust emissions, meeting stricter environmental standards.

Despite facing numerous challenges, drum drying technology maintains its important position in specific fields due to its unique advantages. When choosing a drying technology, manufacturers need to consider various factors, including material characteristics, product quality requirements, investment budget, and operating costs. As technological innovation continues to advance, drum drying technology will undoubtedly find suitable applications in a wider range of fields, providing reliable technical support for industrial production.

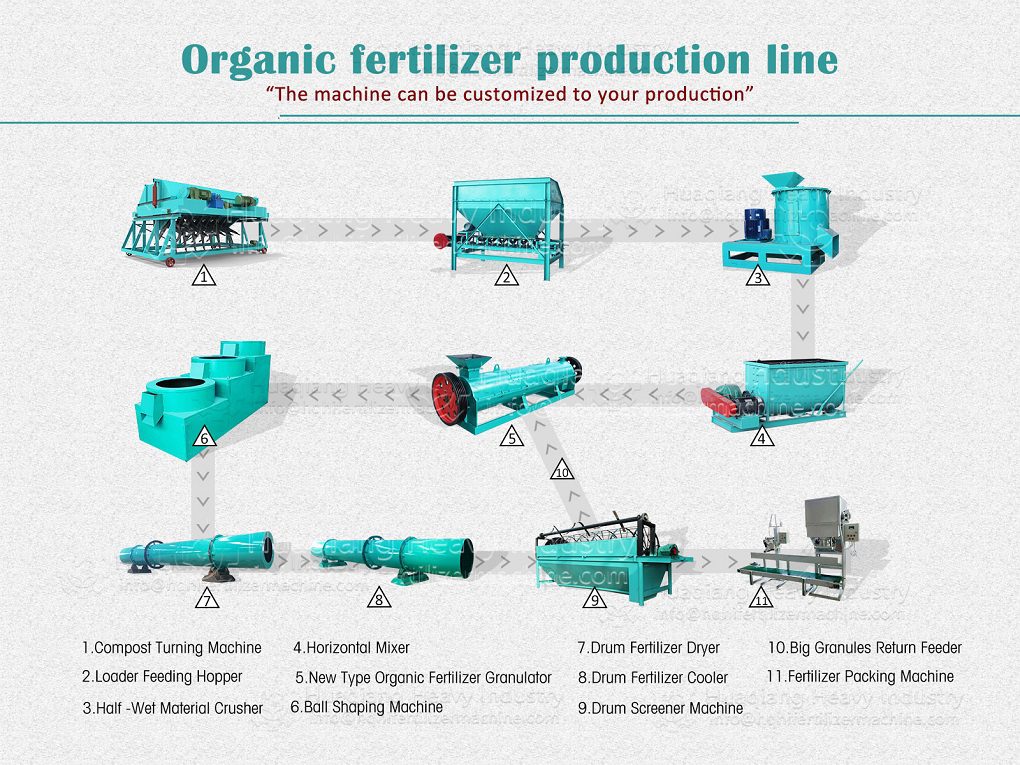

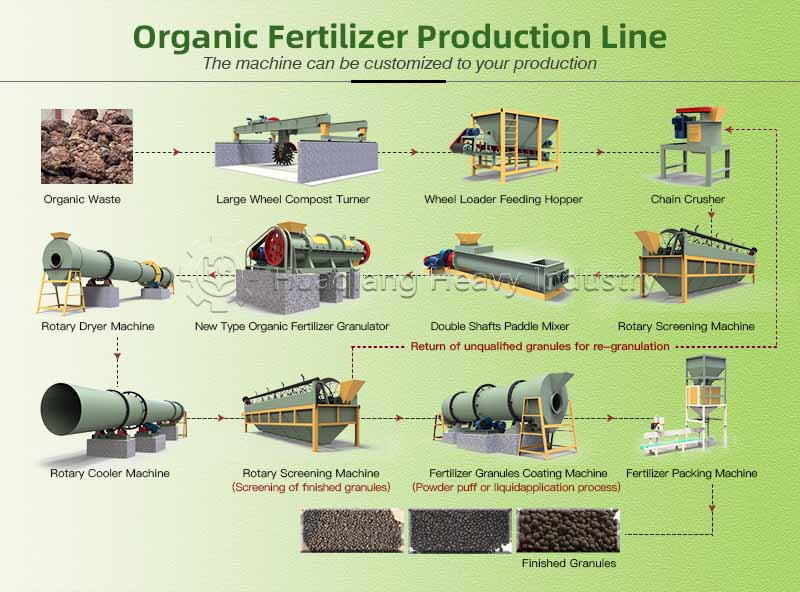

Integrated Fertilizer Production Systems

While drum drying serves specific applications, modern fertilizer production relies on integrated systems of professional fertilizer manufacturing equipment tailored to product type. For compound fertilizers, a complete npk fertilizer line is essential, starting with precise formulation using an npk blending machine or npk bulk blending machine for dry powders. Granulation is then achieved via a disc granulator (forming the core of a disc granulation production line) or a double roller press granulator for compaction. In contrast, a bio organic fertilizer production line begins with organic waste processing, where a double screws compost turning machine is key for aerobic fermentation. The cured compost is then shaped in an organic fertilizer disc granulation production line, where the disc granulator for shaping creates uniform organic pellets. Together, the crushers, mixers, turners, and granulators form the comprehensive suite of fertilizer raw material processing machinery and equipment, enabling efficient transformation of diverse raw materials into high-quality fertilizer products.