Modern agriculture is undergoing a green revolution, and the sophisticated organic fertilizer production line stands at the heart of this transformation. This complete organic fertilizer line efficiently converts agricultural waste into valuable nutrients through advanced bio organic fertilizer production methods. The system achieves a remarkable metamorphosis from “waste” to “treasure,” creating sustainable fertilizer that enriches soil while reducing environmental impact. This innovative approach represents a circular economy solution that benefits both farmers and the ecosystem.

Precision Configuration: A Symphony of Collaborative Equipment

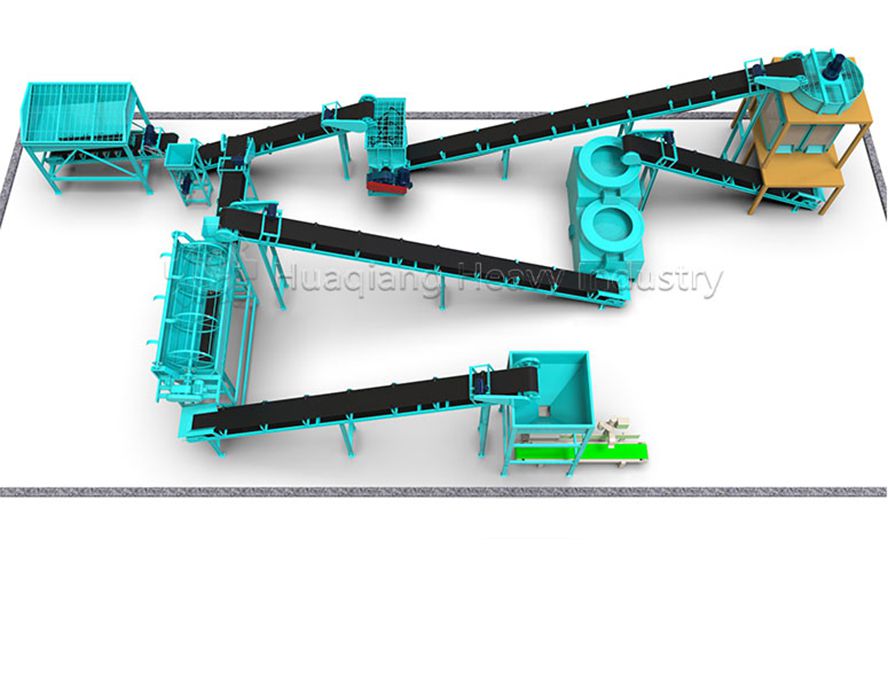

A complete organic fertilizer production line resembles a well-orchestrated symphony, where each piece of equipment plays an indispensable role. From the crushing and screening of raw material pretreatment equipment to the microbial transformation in fermentation systems, and further to the shaping process in granulation equipment—each step coordinates precisely to ensure the high quality of the final product.

Core Equipment: Key Players in the Transformation Process

Fermentation equipment serves as the heart of the organic fertilizer line, utilizing microbial magic to convert organic waste into stable organic matter. The compost turner acts as the “respiratory organ” during fermentation, providing sufficient oxygen through regular turning. Granulation equipment functions as the “stylist,” shaping the fermented material into uniform pellets that significantly improve storage and application convenience.

Finishing and Packaging: The Perfect Finale

Drying and cooling equipment ensure fertilizer pellets achieve ideal moisture content and temperature, while screening equipment acts as a strict quality inspector, guaranteeing consistent particle size. Optional coating equipment dresses the pellets in a protective layer that enhances moisture resistance and controls nutrient release rates. Finally, automatic packaging machines “dress” the finished product, completing the journey from production to market.

The intelligent control system serves as the “brain” of the organic fertilizer production line, monitoring and adjusting key parameters through PLC and automation instruments to ensure efficient and stable operation of the entire production line. This complete organic fertilizer line not only achieves resource recycling but also provides strong support for sustainable agricultural development, truly turning waste into “black gold” that nourishes our land.