Understanding the Rotary Drum Technology

The rotary drum method represents a fundamental mechanical process widely employed across various industrial sectors, with particularly significant applications in fertilizer manufacturing. This technology utilizes a horizontally oriented cylindrical drum that rotates at controlled speeds, creating continuous tumbling and mixing actions for materials inside. In the context of NPK fertilizer production process, this method has become indispensable for creating uniform, high-quality fertilizer granules.

Core Working Principle

At the heart of this technology lies the rotary drum granulator, a robust machine designed to transform powdered raw materials into consistent granules. As the drum rotates, materials undergo a sophisticated agglomeration process where particles continuously collide and adhere to each other, gradually forming spherical granules. The drum granulation process can be precisely controlled by adjusting rotation speed, tilt angle, and moisture content to achieve desired granule characteristics.

Application in NPK Fertilizer Manufacturing

In the NPK manufacturing process, the rotary drum granulator serves as the central component of the production line. The complete NPK fertilizer production line typically begins with raw material preparation, followed by precise batching and initial mixing. The materials then enter the drum granulator where the actual granulation occurs. The rotary granulator efficiently handles various fertilizer formulations, including complex balanced blends like 20-20-20 fertilizers, ensuring homogeneous nutrient distribution throughout each granule.

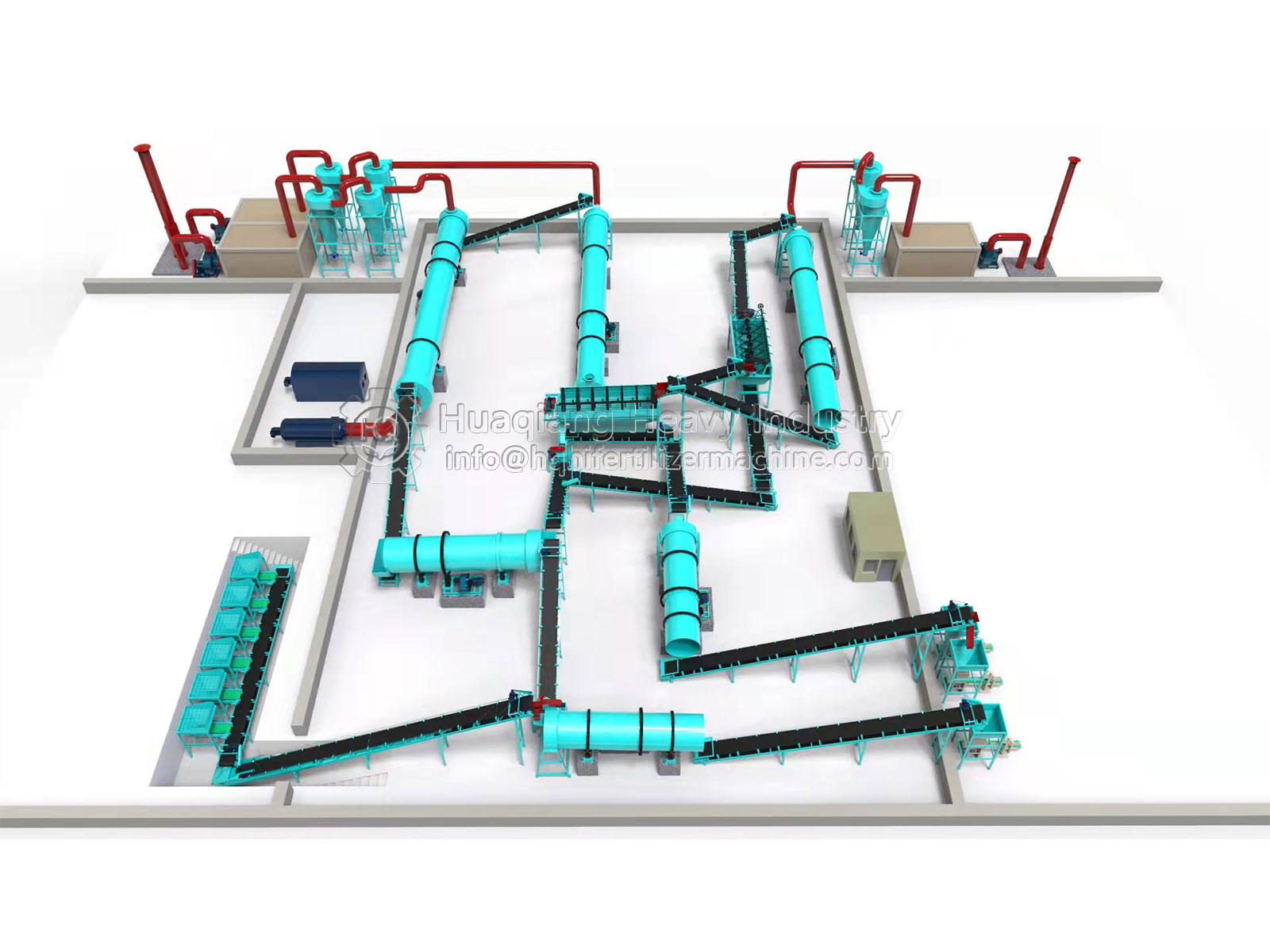

Integration with Supporting Equipment

A comprehensive NPK production line incorporates multiple interconnected machines that work in harmony with the drum granulator. Following the granulation stage, the material typically passes through a rotary screener, which separates properly sized granules from undersized or oversized particles. The screening process ensures product consistency and allows for recycling of off-spec materials back into the production stream. This integrated approach maximizes efficiency and minimizes waste in the NPK fertilizer manufacturing process.

Technical Advantages in Fertilizer Production

The drum granulator offers numerous benefits that make it particularly suitable for fertilizer production machine applications. Its high throughput capacity makes it ideal for large-scale operations, while its ability to produce granules with excellent physical strength ensures product durability during storage and transportation. The technology’s flexibility allows manufacturers to easily adjust formulations and production parameters to meet specific market requirements. Furthermore, modern NPK fertilizer production technology has enhanced the basic drum granulation process with automated controls and monitoring systems, ensuring consistent product quality and operational efficiency.

Process Optimization and Control

Successful implementation of the rotary drum method in NPK fertilizer production requires careful attention to process parameters. Operators must maintain optimal rotation speeds to ensure proper tumbling action without excessive centrifugal force. Moisture content must be precisely controlled to facilitate granule formation while avoiding over-wetting. The internal design of the drum, including lifters and baffles, can be customized to optimize material flow and granule formation. These considerations are crucial for maintaining the efficiency and reliability of the fertilizer production machine.

Future Developments and Sustainability

As the fertilizer industry evolves, rotary drum technology continues to advance. Modern designs focus on energy efficiency, reduced environmental impact, and enhanced automation. The integration of smart sensors and control systems allows for real-time monitoring and adjustment of the drum granulation process, contributing to more sustainable manufacturing practices. These advancements ensure that the rotary drum method remains a cornerstone of efficient and environmentally responsible NPK fertilizer production technology.

Conclusion

The rotary drum granulator has established itself as a cornerstone technology in modern fertilizer manufacturing, offering unparalleled efficiency in the NPK manufacturing process. As a central component of any comprehensive NPK fertilizer production line, this fertilizer production machine demonstrates remarkable versatility in handling various raw materials and formulations.

While alternative methods like fertilizer granules compaction using specialized fertilizer compaction machine equipment exist, drum granulation remains the preferred choice for many producers. The drum granulator excels in creating uniform, high-quality granules through a continuous process that optimizes production efficiency and product consistency.

Compared to fertilizer compaction techniques, the rotary drum method offers superior control over particle size distribution and nutrient homogeneity. This advanced fertilizer production machine technology ensures precise nutrient blending throughout the NPK manufacturing process, resulting in products that meet exact agricultural specifications.

As the global demand for agricultural products continues to grow, the rotary drum granulator will remain essential to sustainable fertilizer production. Its reliability and adaptability within the complete NPK fertilizer production line make it indispensable for meeting both production targets and environmental standards, solidifying its position as the leading solution in modern drum granulation technology.