As an indispensable material handling equipment in modern industrial production, screw conveyors are widely used in various industries due to their simple structure, easy operation, and good sealing performance. Understanding their working principles and mastering troubleshooting methods for common faults are crucial for ensuring production efficiency and equipment longevity.

Working Principle: Ingenious Transformation of Mechanical Energy

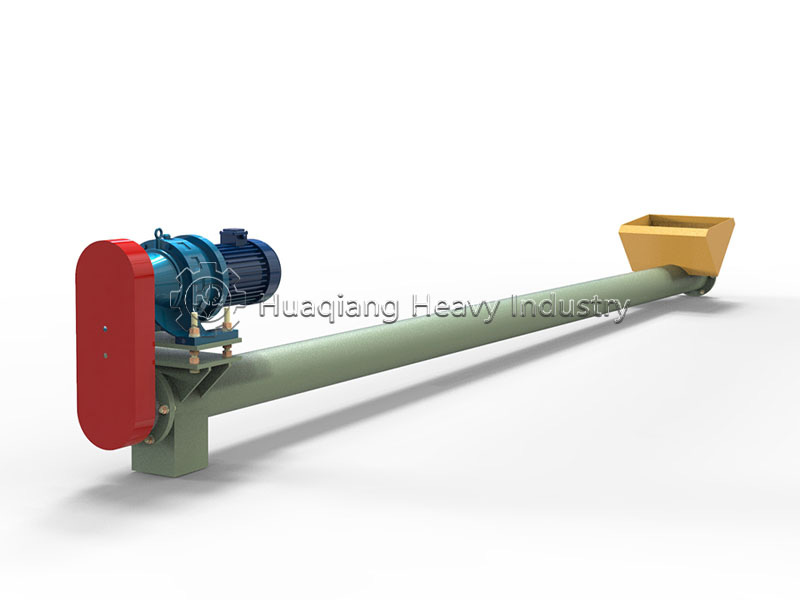

The core working principle of a screw conveyor involves using rotating spiral blades to push materials axially within a fixed housing. This process essentially converts mechanical energy into the kinetic and potential energy of materials, achieving continuous material transportation. The specific working process can be divided into three key stages:

First is the material entry stage. Materials enter the conveyor housing through the feed inlet and fall into the cavity formed by the spiral blades and housing. The design of this stage directly affects subsequent conveying efficiency and stability.

Next is the spiral pushing stage. The motor drives the spiral shaft to rotate, and the spiral blades turn accordingly. The helical surface of the blades generates axial thrust on the materials, which must overcome the friction between materials and housing, and between materials and blades. The magnitude of thrust depends on the blade’s helix angle, rotation speed, and material characteristics.

Finally, the material discharge stage. Under continuous thrust, materials move forward along the inner wall of the housing, following the rotation direction of the spiral blades, and are eventually discharged from the outlet, completing the entire conveying process.

Common Fault Diagnosis and Treatment

During long-term operation, screw conveyors mainly experience three types of typical faults: reduced conveying efficiency, abnormal noise and vibration, and equipment jamming. Each fault has its specific causes and solutions.

Reduced Conveying Efficiency or Material Blockage

This is the most common fault type. When the feeding speed exceeds the equipment’s designed conveying capacity, material accumulation occurs inside the housing; materials with excessive moisture content or high viscosity adhere to blades and housing walls, reducing effective conveying space; severe wear of spiral blades decreases pushing capacity. Solutions include adjusting feeding speed, preprocessing high-moisture materials, regularly cleaning equipment internals, and timely replacing worn blades.

Abnormal Noise and Vibration

Such faults usually indicate installation issues or wear in equipment components. Misalignment between spiral shaft and motor shaft causes uneven force distribution during operation; insufficient bearing lubrication generates friction noise; metal fragments or other foreign objects inside the housing collide with blades. Corresponding solutions include adjusting shaft alignment, regularly lubricating bearings, removing foreign objects, and installing filtration devices at feed inlets.

Spiral Shaft Jamming

This is a relatively serious fault requiring emergency treatment. Large foreign objects, deformed spiral blades, or failed motor overload protection can all cause this fault. Solutions include removing jammed objects, correcting or replacing deformed blades, and inspecting motor protection devices. If not addressed promptly, such faults can lead to motor burnout and greater losses.

By deeply understanding the working principles of screw conveyors and mastering diagnostic and treatment methods for common faults, operators can better maintain equipment and ensure stable production line operation. Regular equipment inspections and preventive maintenance are key measures to prevent faults and extend equipment service life.

In conclusion, screw conveyors serve as vital connecting components across various fertilizer production systems, ensuring seamless material transfer between different processing stages. Their reliable operation is particularly crucial in complex production lines such as the npk fertilizer production line and organic fertilizer production line, where they transport raw materials to key processing equipment including disc granulator machine, double roller press granulator, and various fertilizer granulator systems. In the comprehensive npk fertilizer line, screw conveyors work alongside npk blending machine to ensure homogeneous material distribution before granulation. Similarly, in bio organic fertilizer production line setups, they efficiently transport composted materials from windrow machine systems to subsequent processing stages. The integration of screw conveyors within disc granulation production line configurations guarantees consistent material flow through all fertilizer granulation processes, significantly enhancing overall production efficiency and system reliability. Proper maintenance and operation of these conveyors ultimately determine the smooth functioning of entire fertilizer manufacturing operations, from initial material handling to final product output.