In the global pursuit of sustainable agriculture, organic fertilizer manufacturing technologies are rapidly developing, forming a complete technological system centered on biological fermentation, supplemented by physical-chemical conversion, and enhanced by deep processing technologies. These technologies transform agricultural waste into valuable resources, achieving a win-win situation for environmental protection and agricultural production.

Biological Fermentation Technology: Harnessing Natural Forces

Aerobic fermentation technology is currently the most widely used organic fertilizer production method worldwide. Through microbial action, organic wastes such as livestock manure and crop straw are decomposed and transformed under sufficient oxygen conditions. The high temperatures generated during fermentation not only eliminate pathogens and weed seeds but also effectively degrade complex organic matter like cellulose. In large agricultural bases like Shouguang in China, this technology has achieved large-scale production of 200,000 tons of organic fertilizer annually.

Anaerobic fermentation technology is particularly suitable for treating organic waste with high moisture content. In enclosed environments, microorganisms decompose organic matter under oxygen-free conditions while producing usable biogas energy. The United States and European Union countries often combine this technology with large-scale biogas projects, achieving dual benefits of energy recovery and fertilizer production. The recently developed anaerobic-aerobic two-stage fermentation technology combines the advantages of both methods, demonstrating excellent results in agricultural waste treatment projects in Spain and Germany.

Physical-Chemical Conversion: Breakthroughs in Technological Innovation

For difficult-to-degrade organic raw materials, physical-chemical conversion technologies provide new solutions. Pyrolysis carbonization technology produces biochar with special structures by treating lignocellulosic materials at high temperatures in low-oxygen environments. This material not only contains abundant organic carbon but also improves soil physical properties, commonly used in Europe for soil improvement in high-end organic agriculture.

Acid-alkali hydrolysis technology uses chemical means to break down the complex structure of cellulose, converting it into easily absorbable small molecules. This technology is particularly suitable for producing highly active liquid organic fertilizers, applied in special crop cultivation in countries like the United States. Oxidation degradation technology utilizes oxidants to treat organic waste, producing liquid fertilizers with good water solubility, suitable for resource utilization of urban organic waste.

Deep Processing Technology: Enhancing Product Value

Granulation technology transforms powdered organic fertilizer into granular form, greatly improving product commercial value and usability. Disc granulators and double-roller extrusion granulators are two mainstream equipment types, with the former producing uniform spherical particles and the latter excelling in energy efficiency. In places like Zhejiang, China, these technologies are also used to produce specialized fertilizers with added trace elements.

Functional additive technology significantly enhances organic fertilizer effectiveness by introducing beneficial microorganisms or special additives. Adding functional microorganisms like nitrogen-fixing bacteria and phosphorus-solubilizing bacteria can produce bio-organic fertilizers; adding components like humic acid and seaweed extracts enables production of specialized fertilizers for specific crops. Through technological innovation, companies like Kingenta Group have successfully developed high-end products with organic matter content exceeding 50%.

Intelligent Control and Environmental Technology

Modern organic fertilizer production increasingly emphasizes intelligent control and environmental protection. Through real-time monitoring of parameters like temperature and oxygen during fermentation using sensors, combined with automated control systems, fermentation cycles are shortened to within 15 days. Simultaneously, advanced dust removal and deodorization equipment effectively control environmental pollution during production, achieving clean production.

With increasing global emphasis on sustainable agriculture, organic fertilizer manufacturing technologies will continue developing toward greater efficiency, environmental friendliness, and intelligence. These technological advancements not only improve organic fertilizer quality and yield but also provide strong support for global agricultural sustainable development, promoting the establishment and improvement of circular agriculture models.

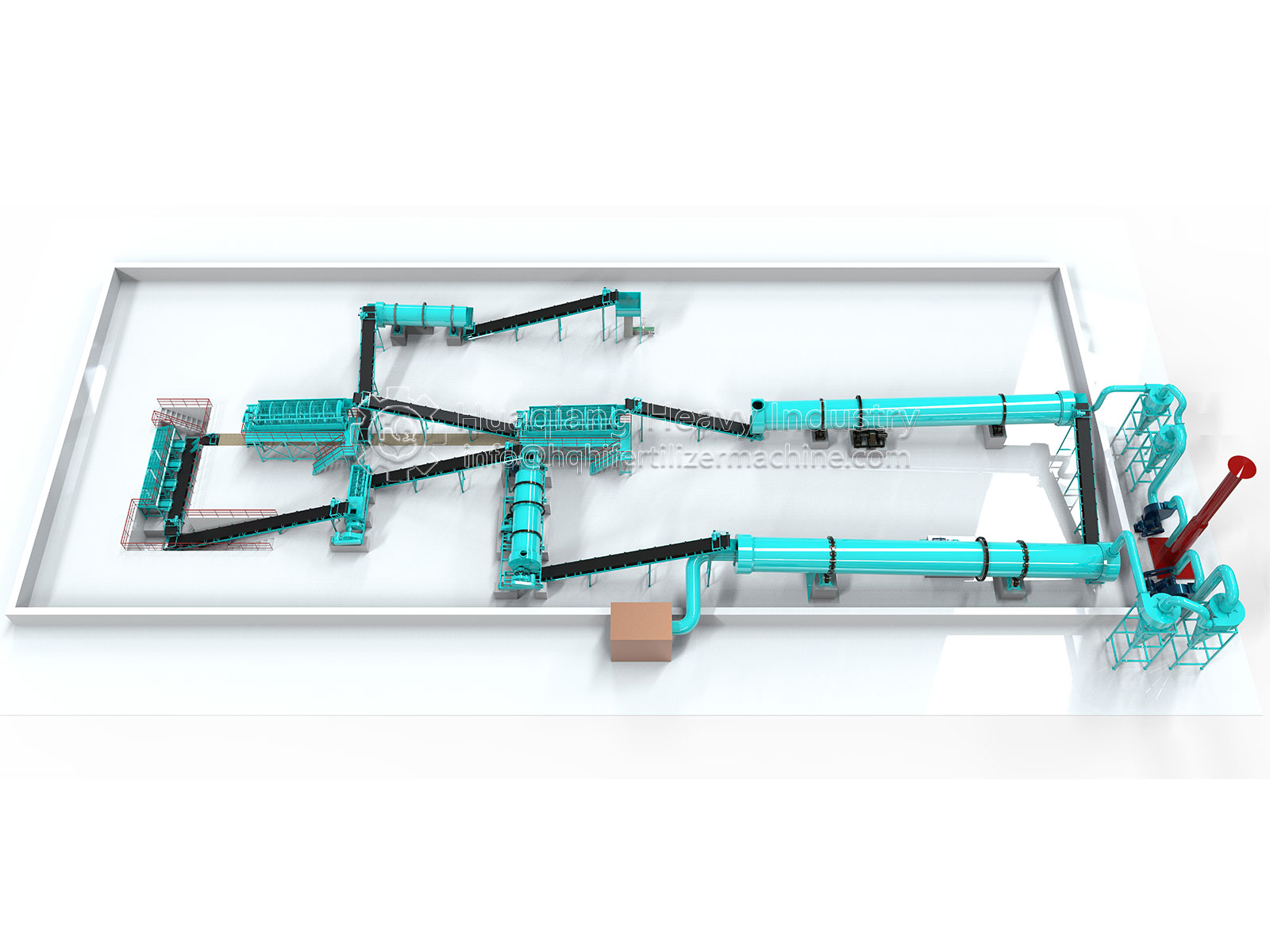

Integrated Systems for Advanced Organic Fertilizer Production

Modern organic fertilizer manufacturing technology is embodied in comprehensive organic fertilizer production line systems that integrate various specialized equipment. The process begins with efficient organic fertilizer fermentation equipment, including the chain compost turning machine for continuous operation and the large wheel compost turning machine for large-scale processing. These systems optimize biological decomposition through controlled aeration and temperature management. Following complete fermentation, the bio organic fertilizer production line incorporates additional microbial inoculation stages to enhance biological activity before proceeding to granulation.

The final stage of processing involves the organic fertilizer granulator, which transforms matured organic matter into uniform, market-ready pellets. This integrated approach demonstrates how advanced manufacturing technologies work synergistically—from initial biological transformation through fermentation to final physical shaping—to produce high-quality organic fertilizers. The continuous innovation in organic fertilizer manufacturing technology enables efficient conversion of diverse organic waste streams into valuable soil amendments while improving production efficiency, product consistency, and environmental performance. These technological advancements support the growing global demand for sustainable agricultural inputs that enhance soil health, promote crop productivity, and contribute to circular economy principles through effective organic waste utilization.