The single silo single weight automatic batching system is an automated equipment used for precise metering and mixing of multiple materials. With its core advantages of high precision and high automation, it is widely used in various industrial fields such as chemical, pharmaceutical, food, and building materials. This system precisely measures each material through independent weighing units and then mixes them according to preset formula ratios, fundamentally ensuring the stability of product quality and significantly improving the efficiency of the production process. It is a key equipment for achieving refined batching in modern industrial production.

Equipment Structure and Composition

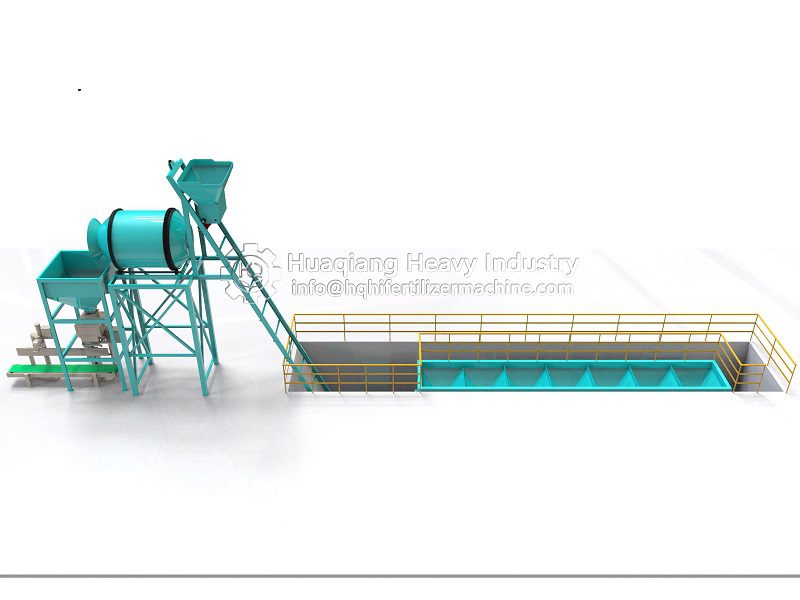

The single silo single weight automatic batching system adopts a modular design, with each component working together to achieve precise batching. Its core structure mainly consists of the following six parts:

- Material Bins (Raw Material Storage Unit)

As the core component for raw material storage, the material bins adopt an independent design, with each bin corresponding to one type of raw material, effectively preventing cross-contamination of different materials. The bin material can be selected from stainless steel, carbon steel, etc., depending on the characteristics of the raw materials. In some special scenarios (such as food and pharmaceuticals), polished stainless steel is used to ensure compliance with industry hygiene standards. The top of the bin is usually equipped with a dust cover and a level gauge to monitor the raw material inventory in the bin in real time, preventing material shortages or overflows.

- Weighing Unit (Core of Precise Measurement)

The weighing unit is crucial for ensuring batching accuracy. Each material bin is equipped with an independent high-precision electronic scale, whose range and accuracy can be customized according to batching requirements (the conventional accuracy range is ±0.1% to ±0.5%). The electronic scale adopts a suspended installation structure to reduce the impact of equipment vibration on measurement accuracy. It is also equipped with a weighing sensor and a data acquisition module, which can transmit weight data to the control system in real time, enabling dynamic weighing monitoring. 3. Conveying Device (Material Transfer Hub)

Responsible for transferring materials from the storage silo to the weighing unit or subsequent mixing equipment. The appropriate conveying method is selected based on the material form (powder, granules, liquid) and conveying distance:

Screw conveyor: Suitable for powder and fine granular materials; its enclosed structure reduces dust leakage, and it offers stable conveying efficiency;

Belt conveyor: Suitable for larger granular or bulk materials; it has adjustable conveying speed and low maintenance costs;

Pneumatic conveying system: For materials that are easily airborne and require high precision (such as pharmaceutical raw materials), a closed pneumatic conveying system is used to avoid material loss and contamination.

- Mixer (Material Homogenization Equipment)

Used to uniformly mix multiple materials according to the formula ratio after precise weighing. Different types of mixing equipment can be selected based on material characteristics, such as ribbon mixers (suitable for powder and granular mixing), paddle mixers (suitable for high-viscosity materials), and V-type mixers (suitable for high-precision mixing scenarios in pharmaceuticals, food, etc.). The mixer is equipped with time control and speed adjustment functions to ensure that the mixing uniformity meets production requirements.

- Control System (Equipment Operation Hub)

Using a PLC (Programmable Logic Controller) or microcomputer control system, this is the “brain” of the entire batching system. The system has the following core functions:

Formula management: Can store hundreds of different formulas, supporting quick formula recall and modification;

Process control: Automatically controls all process actions such as material conveying, weighing, mixing, and unloading, enabling unmanned operation;

Data monitoring: Real-time display of the operating status of each link, material weight, formula execution progress, and other data, supporting data recording and traceability;

Fault alarm: When there is a shortage of materials, overweight, equipment failure, etc., it will promptly issue an audible and visual alarm and display the cause of the fault.

The control system is equipped with a user-friendly human-machine interface (HMI), using a touch screen for operation. Parameter settings are simple and intuitive, making it easy for operators to use.

6. Safety Protection System (Ensuring Operational Safety)

To ensure the safety of equipment and operators, the system is equipped with comprehensive safety protection devices:

Overload protection: When the weight of the weighing unit exceeds the rated range, the power supply to the conveying device is automatically cut off to prevent equipment damage;

Emergency stop device: Emergency stop buttons are installed at critical positions of the equipment for quick shutdown in case of emergencies;

Dustproof and explosion-proof design: For flammable and explosive environments such as chemical and pharmaceutical industries, explosion-proof motors and sealed structures are used, meeting explosion-proof rating requirements;

Protective barriers and warning signs: Protective barriers are installed for moving parts, and operation warning signs are posted at critical positions of the equipment.

Working Principle

The single-bin automatic weighing and batching system achieves automated batching through a closed-loop process of “preset formula → precise metering → coordinated conveying → uniform mixing → automatic unloading”. The specific working steps are as follows:

Formula parameter setting: The operator inputs the types of materials required for production, the proportion of each material, and the total batching amount through the human-machine interface. The system stores the parameters and generates a production task order;

Material conveying and weighing: After the system starts, it controls the opening of the discharge valve of the corresponding material bin according to the formula sequence, and the material enters the independent weighing unit through the conveying device. The electronic scale collects material weight data in real time and feeds it back to the control system. When the weight reaches the preset value, the control system precisely closes the discharge valve, completing the metering of that material;

Multi-material coordinated metering: Following the above steps, the independent weighing of all formula materials is completed in sequence, ensuring that the weight error of each material is controlled within the allowable range;

Mixing and unloading: After all materials are metered, the control system controls the opening of the discharge door of the weighing unit, and the materials enter the mixer. The mixer operates according to the preset time and speed. After the materials are uniformly mixed, the mixed materials are automatically unloaded to the subsequent process (such as packaging machine, granulator, etc.);

Cyclic operation: After one batching is completed, the system automatically cleans the residual materials in the weighing unit (some equipment is equipped with an automatic blowing function), and executes the next batching task according to the production plan, achieving continuous production. III. Core Features of the Equipment

The single silo single weight automatic batching system demonstrates significant performance characteristics in industrial production thanks to its advanced design and technological advantages:

- High Batching Accuracy, Ensuring Stable Product Quality

The independent weighing design of “one bin, one scale” avoids the problem of material interference in traditional mixed weighing. Combined with high-precision electronic scales and dynamic weighing algorithms, it ensures that the batching error for each material is controlled within ±0.1% to ±0.5%. Precise batching ratios effectively prevent product quality fluctuations caused by deviations in raw material ratios, improving the product pass rate.

- High Degree of Automation, Improving Production Efficiency

The entire process, from formula setting, material conveying, weighing, mixing to unloading, is automatically controlled, requiring no manual intervention, significantly reducing the intensity of manual labor. Compared with traditional manual batching, production efficiency is increased by 30% to 50%, while avoiding human errors in the manual batching process (such as weighing errors, incorrect batching sequence, etc.), making it suitable for large-scale continuous production.

- Strong Adaptability, Meeting the Needs of Multiple Scenarios

It can flexibly adapt to different forms of materials (powder, granules, liquids, blocks, etc.), supports rapid switching of multiple formulas, and meets the production needs of different industries such as chemical, pharmaceutical, food, and building materials. The equipment’s weighing range, conveying speed, mixing time, and other parameters can be customized according to actual production needs, providing strong scalability.

- Convenient Operation and Low Maintenance Costs

The user-friendly human-machine interface makes parameter setting, formula management, and equipment monitoring simple and intuitive. Operators can be trained quickly. The equipment adopts a modular structure design, making the assembly and disassembly of components convenient. Key wear parts (such as conveyor belts and weighing sensors) are highly interchangeable, facilitating maintenance and reducing maintenance costs.

- Safe and Environmentally Friendly, Compliant with Industry Standards

A complete safety protection system ensures the safety of equipment and personnel, reducing the risk of production accidents. The enclosed material bins and conveying system effectively reduce dust leakage and material volatilization, meeting environmental protection requirements; for industries such as food and pharmaceuticals, the equipment materials and structural design comply with GMP and other industry hygiene standards, preventing material contamination. IV. Typical Application Scenarios

Chemical Industry: Used for the raw material blending of products such as coatings, dyes, and rubber, precisely controlling the proportion of each component to ensure stable product performance;

Pharmaceutical Industry: Suitable for high-precision ingredient dispensing of pharmaceutical raw materials (powders, granules), complying with GMP standards and avoiding cross-contamination;

Food Industry: Used for the mixing and blending of food raw materials such as flour, starch, and additives, ensuring consistent food taste and quality;

Building Materials Industry: Applicable to the raw material proportioning of building materials such as concrete, mortar, and tile adhesive, improving performance indicators such as material strength;

Fertilizer Industry: Used for the mixing of raw materials for products such as NPK compound fertilizers and organic-inorganic compound fertilizers, precisely controlling the proportion of nutrients such as nitrogen, phosphorus, and potassium.

Integrating Precision Batching into Modern Granulation Systems

The single silo single weight automatic batching system is the critical first step in ensuring formula accuracy for modern fertilizer production. In a complete npk fertilizer production line, this precision is realized by a npk blending machine, which ensures the exact N-P-K ratio before the material enters the granulation stage. The uniformly blended powder then proceeds to the core fertilizer granulation processes, where it is shaped into final product form.

The choice of granulation technology depends on the product type. For standard compound fertilizers, a disc granulator for shaping spherical pellets is often used in a disc granulation production line. Alternatively, a double roller press granulator forms the basis of a dry roller press granulator production line. This same principle of precise batching and subsequent shaping applies to the organic fertilizer production line and the bio organic fertilizer production line. Whether the final shaping is done by a disc granulator machine or another type of fertilizer granulator, the integration of automated, high-accuracy batching with advanced granulation is fundamental to producing consistent, high-quality fertilizers that meet specific agricultural nutrient requirements.