Organic fertilizer is a natural product made from decomposing organic materials such as animal and plant residues, livestock manure, and industrial organic waste through microbial fermentation. The process focuses on harmless treatment and nutrient activation, ensuring safety and efficiency. Below is a detailed overview of the complete production process from raw materials to finished products.

1. Raw Material Pretreatment: Laying the Foundation for Fermentation

Pretreatment is the first step, aiming to remove impurities and adjust material properties to create ideal conditions for microbial activity. Raw materials come from diverse sources, including livestock manure, crop straw, and food processing waste. These materials are screened to remove plastics and metals, then crushed into 5-10 mm particles to increase microbial contact area. Moisture content is adjusted to 55%-60% (a state where material holds together when squeezed but breaks apart easily), and the carbon-to-nitrogen ratio is balanced to 25:1-30:1 (e.g., by mixing chicken manure with straw), while pH is maintained at 6.5-7.5. To speed up fermentation, 0.1%-0.5% microbial inoculants like Bacillus subtilis can be added, shortening the cycle and reducing odors.

2. Microbial Fermentation and Decomposition: The Core Harmless Process

Fermentation is the heart of organic fertilizer production, where microbial decomposition achieves harmless treatment and nutrient conversion. Pretreated materials are piled into long rows (2-3 meters wide, 1.2-1.5 meters high) and covered with breathable film for insulation and ventilation. Within 2-3 days, the pile temperature rises to 55-65°C, entering a high-temperature phase that lasts 5-7 days, effectively killing pathogens, insect eggs, and weed seeds. Regular turning (typically 4-6 times) is required to add oxygen, distribute heat evenly, and prevent temperatures from exceeding 70°C, which could harm microbes. After the high-temperature phase, the pile cools to ambient temperature over 7-10 days, with organic matter further converting into stable humus. Completion is indicated by dark brown color, no foul odor, loose texture, and compliance with hygiene standards (e.g., roundworm egg mortality ≥95%).

3. Post-Processing and Refinement: Enhancing Product Quality

Decomposed coarse fertilizer undergoes refinement to meet commercial standards. It is first crushed and sieved to control particle size to 2-5 mm, ensuring uniformity. Then, tests are conducted for heavy metals, pathogens, and nutrient content (organic matter ≥30%, total nutrients ≥5%), which must comply with national standards. Depending on needs, granulation can be applied to produce pelletized fertilizer for easier storage and mechanical application, or additives like humic acid and micronutrients can be incorporated to enhance functionality. If the product has high moisture or odors, drying and deodorizing processes are used to reduce moisture to ≤15%.

4. Packaging and Storage: Ensuring Product Stability

Processed organic fertilizer is weighed and packaged, with common sizes being 25-50 kg bags (for agriculture) or small packages (for home gardening). Labels must clearly show product information, including composition, standards, and production date. Finished products are stored in dry, ventilated warehouses away from chemicals, with stacking height limited to 10 layers to prevent moisture clumping. The entire production process also emphasizes environmental protection, such as treating exhaust gases, leachate, and dust, ensuring sustainable development.

In summary, organic fertilizer production is a systematic bioengineering process, where each step from pretreatment to storage interconnects, ultimately yielding safe and efficient fertilizer to support green agriculture.

Conclusion: The Integrated System of Organic Fertilizer Manufacturing

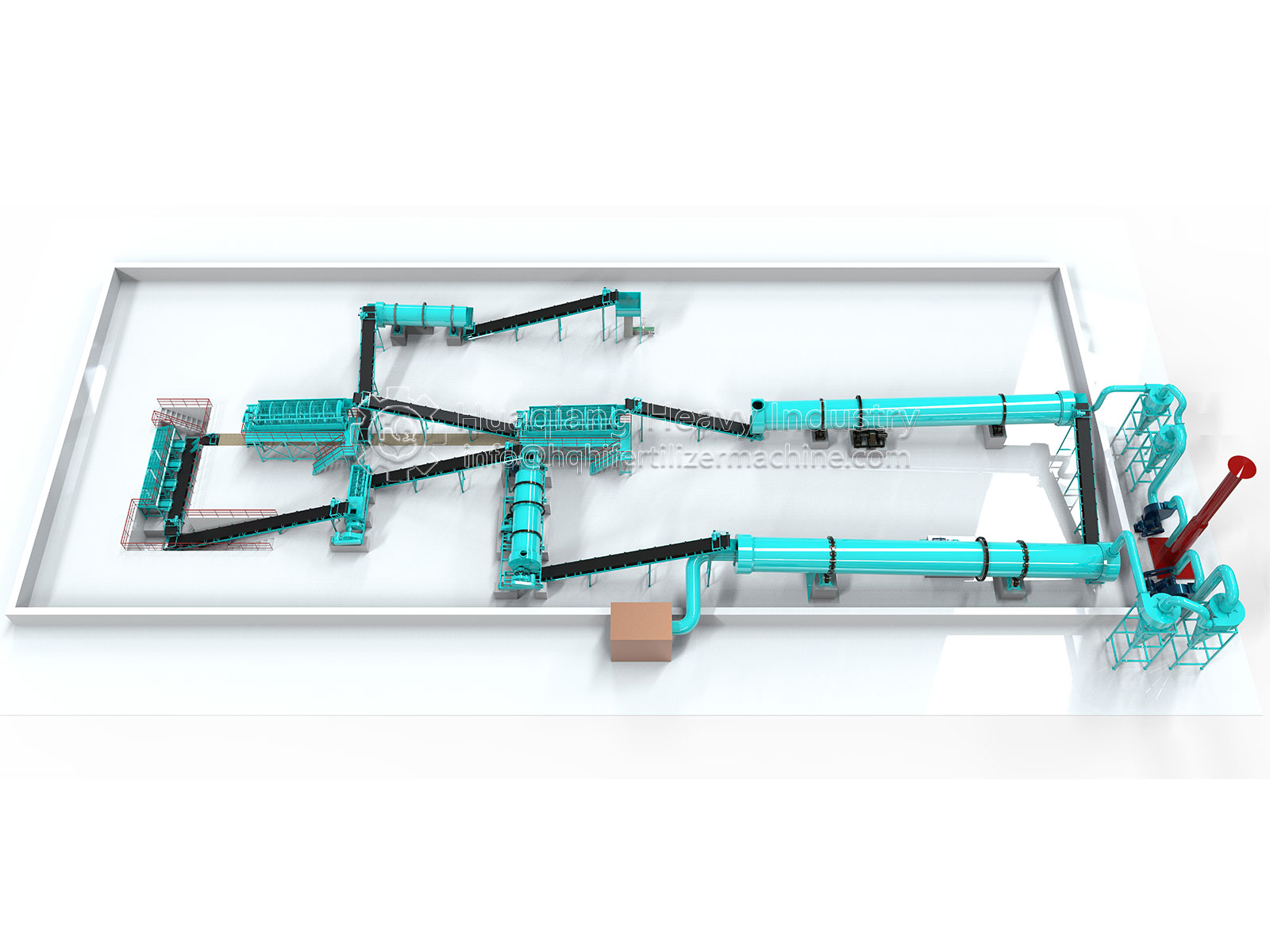

In summary, organic fertilizer production constitutes a sophisticated, interconnected system where each phase—from initial organic fertilizer fermentation to final packaging—is critical for producing safe, high-quality products. The entire organic fertilizer production line or bio organic fertilizer production line is designed to transform raw organic waste into a stable agricultural resource efficiently. The core fermentation stage relies on advanced fermentation composting turning technology, implemented by robust equipment such as the chain compost turning machine or large wheel compost turning machine, to ensure effective aeration and decomposition.

Subsequent refinement often involves granulation to improve handling and application properties. Here, machinery like the versatile new type two in one organic fertilizer granulator or the high-capacity rotary drum granulator (also referred to as a drum granulator) plays a pivotal role in shaping the final product. Ultimately, the success of organic fertilizer manufacturing hinges on integrating these specialized technologies—from turning machines for decomposition to the appropriate organic fertilizer granulator—into a seamless, environmentally conscious process that supports sustainable agriculture.