Climate Characteristics and Equipment Operation Challenges

Southeast Asia, as a crucial region for global agricultural development, experiences continuous growth in the demand for organic fertilizer. However, the region’s unique climate—an average annual temperature of 25-30 degrees Celsius and relative humidity of 70%-90%, coupled with a long rainy season lasting several months—poses severe challenges to organic fertilizer production equipment. High temperature and humidity accelerate equipment corrosion, while the rainy season makes it difficult to control the moisture content of raw materials. These problems directly affect the stable operation of the production line and product quality.

Equipment Material and Protection Optimization Solution

Given the climatic characteristics of Southeast Asia, the production line equipment requires comprehensive material upgrades and enhanced protection. Core equipment, including turners, granulators, and mixers, should be treated with double-layer anti-corrosion coatings, and key components should be made of 304 or 316 stainless steel. The motor system needs to be a waterproof and explosion-proof model with a protection rating of IP55 or higher, and moisture-proof isolation devices should be added to critical circuit sections.

A special anti-corrosion solution was adopted for the double-roller extrusion granulator in an organic fertilizer project in Malaysia. The extrusion rollers of this equipment utilize wear-resistant and corrosion-resistant alloy materials. Through special heat treatment and surface treatment processes, they maintain excellent wear resistance while significantly improving corrosion resistance, extending service life by more than three times compared to ordinary materials. This customized material selection effectively solves the problem of equipment wear and tear under high temperature and humidity environments.

Production Process Adaptability Adjustment

The raw material processing stage requires special design for the rainy season. The production line should be equipped with a large raw material drying shed and forced dehydration equipment to ensure that the moisture content of the raw materials is controlled within the ideal range of 40%-60% even during the rainy season. The fermentation workshop adopts a fully enclosed design, equipped with a high-efficiency dehumidification system and mechanical ventilation devices to ensure that the fermentation process is not affected by external humidity.

In the granulation process, traditional granulation equipment is difficult to adapt to the characteristics of high-humidity raw materials. The new stirring tooth granulator, through optimized stirring structure and power configuration, can effectively handle materials with high moisture content, maintaining a stable pelleting rate of over 80%. Simultaneously, the drying system needs to increase heat energy utilization efficiency, ensuring efficient drying even under high-temperature environments through waste heat recovery and intelligent temperature control technology.

Localized Service System Construction

Comprehensive localized services are crucial for the stable operation of equipment. Huaqiang Heavy Industry has established spare parts warehousing centers in major Southeast Asian markets, ensuring delivery of commonly used and easily damaged parts within 3-7 days, and emergency spare parts via a green channel within 48 hours. Technical documentation is provided in both Chinese and English, and the user interface supports multilingual switching, lowering the barrier to entry for local operators.

A remote technical support system provides 24/7 uninterrupted service, allowing customers to obtain timely technical guidance through video conferencing and online diagnostics. During project implementation, the company dispatches experienced engineering teams to provide on-site service, offering comprehensive guidance from equipment installation and commissioning to production operation, and conducting systematic training for local technical personnel to ensure customers can master independent operation and maintenance capabilities.

Project Implementation Case and Effect Verification

A large-scale organic fertilizer production line project in Indonesia fully demonstrates the effectiveness of customized solutions. The project is located in a typical tropical rainforest climate zone with an annual rainfall exceeding 3000 mm. Huaqiang Heavy Industry designed a complete adaptation solution based on local conditions: the equipment adopted reinforced anti-corrosion treatment, the fermentation workshop was equipped with a professional dehumidification system, and the production line layout fully considered ventilation and heat dissipation requirements.

Implementation results show that the production line maintained good operational stability in high-temperature and high-humidity environments, with an annual failure rate of less than 3%. The equipment’s anti-corrosion performance withstood the test of the rainy season, the raw material handling system effectively overcame the challenges posed by high humidity, and the overall production line capacity reached over 98% of the design standard. The client highly praised the equipment’s adaptability and reliability.

Technological Innovation and Continuous Improvement

With the continuous development of the Southeast Asian market, the adaptability technology of the production line is also continuously upgraded. Innovative technologies such as new nano-anti-corrosion coatings, intelligent humidity control systems, and remote operation and maintenance platforms are being gradually promoted and applied. Huaqiang Heavy Industry has established a comprehensive technical database to provide precise customized solutions for each project, taking into account the specific climatic conditions and raw material characteristics of different countries.

Through continuous optimization of equipment configuration and process flow, organic fertilizer production lines in Southeast Asia are developing towards greater adaptability and stability. This has not only helped local businesses improve production efficiency and product quality, but also provided reliable technical support for the sustainable development of the organic fertilizer industry, achieving a dual improvement in economic and environmental benefits.

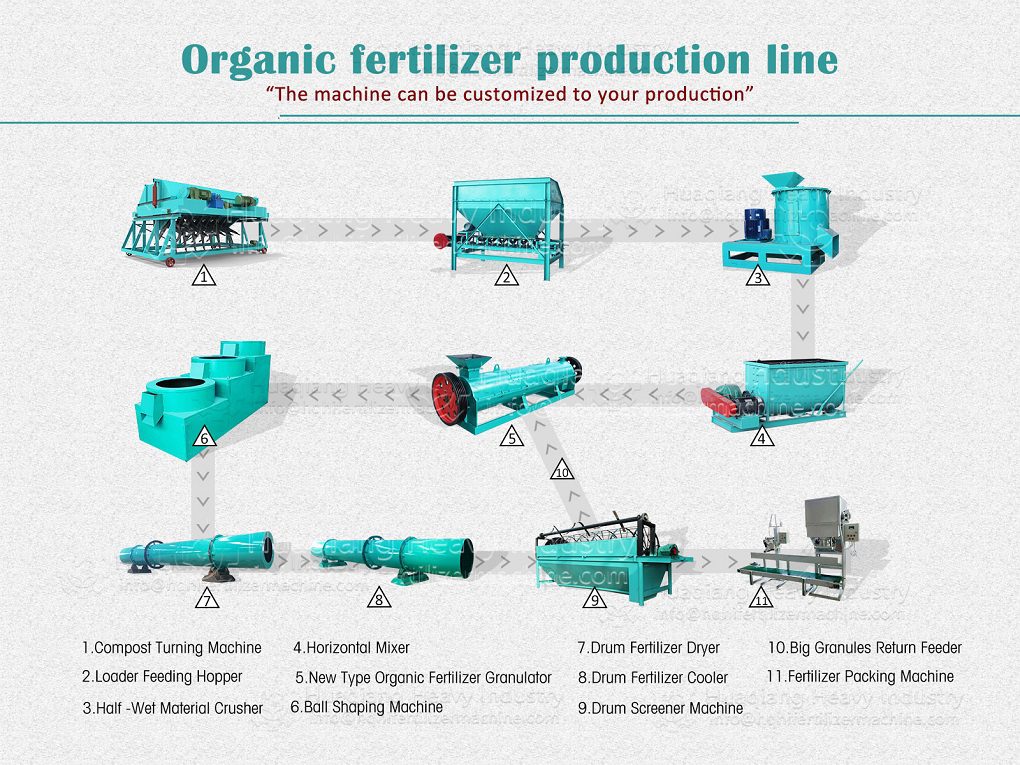

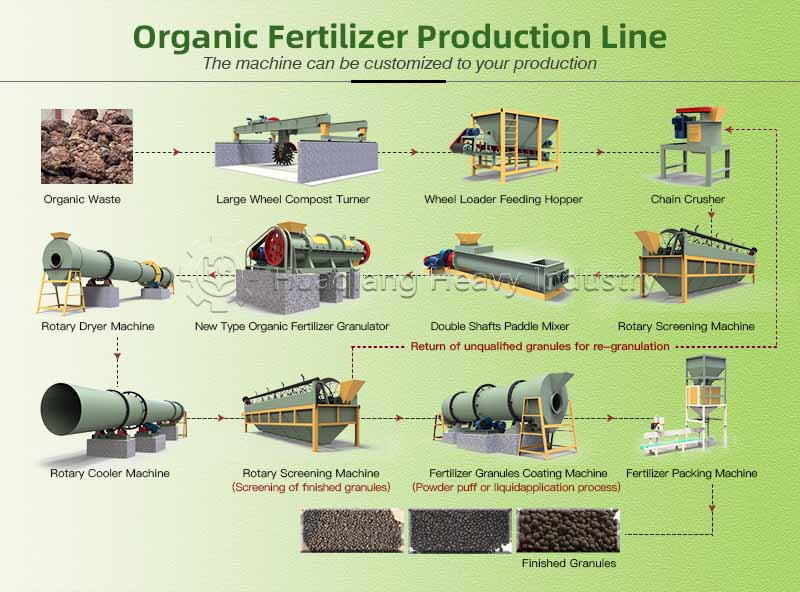

Adaptive Granulation Systems for Humid Climates

Following the robust organic fertilizer fermentation process—optimized with equipment like the chain compost turning machine or large wheel compost turning machine for efficient aeration in high humidity—the critical stage of organic fertilizer production granulation demands specialized equipment. For facilities seeking compact and efficient solutions, the new type two in one organic fertilizer granulator (combining crushing and granulation) or a standard new type organic fertilizer granulator designed for high-moisture materials is ideal. For producers aiming for high-quality spherical granules, a complete organic fertilizer disc granulation production line centered on a corrosion-resistant organic fertilizer disc granulation machine is the optimal choice. This forms the core of a reliable organic fertilizer manufacturing system tailored for Southeast Asia. More complex setups might involve an organic fertilizer combined granulation production line, integrating both extrusion and disc granulation technologies to produce a diverse range of organic fertilizer products from varying raw material consistencies, ensuring operational flexibility and product quality despite challenging climatic conditions.