The sheep manure Organic fertilizer production line mainly uses sheep manure and straw raised by farmers to produce biological Manure by crushing straw and fermenting pig manure together. The technological development of straw resources has become a major issue in ecological agriculture and sustainable development. Add the crushed straw into livestock excreta and other by-products, and then add biological bacteria. After more than ten days, harmless and high-quality Manure can be produced, which solves the problem of straw treatment that has puzzled agricultural production for many years.

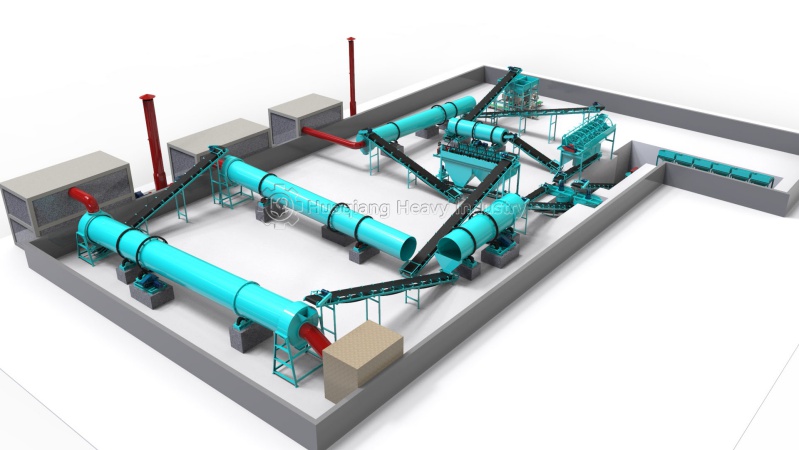

The production line of sheep manure Organic fertilizer with an annual output of 100000 tons is basically a granular Organic fertilizer production line process, because it takes a certain time for a large-scale Organic fertilizer processing production line like 100000 tons to maintain fertility, facilitate transportation and other conditions from transportation to storage to sales. Undoubtedly, granular Manure with moderate hardness is more convenient for storage, transportation and fertility maintenance. Therefore, the production line of Organic fertilizer with an annual output of 100000 tons adopts the processing technology of granular Organic fertilizer production line. Such production line of Organic fertilizer needs to purchase fermentation, flip, smash, granulation, drying, cooling, screening, coating and packaging..jpg)

Step 1: Tank type fermentation equipment. Collect cow manure and urine, mix them with hay and rotting silage to make compost and let it ferment. After fermentation and seeding, use Organic fertilizer composter to fully ferment cow dung, which can only be achieved by timely and uniform turning. Some places are very dry now, while others are very wet, which can affect the fermentation quality.

Step 2: Material crushing equipment. High humidity material crusher is a professional crushing equipment for high humidity, multi fiber materials. Utilizing high-speed rotating blades to crush fibers with good particle size and high efficiency. The semi wet material grinder is mostly used in the production and processing of Manure. It has good effect in crushing chicken manure, humic acid sodium and other raw materials.

Step 3: Mixing and stirring equipment. The Organic fertilizer mixer has fast mixing speed and good uniformity. It can mix 30% viscous materials with liquid. When it works, two rotors with opposite rotating blades stir in the middle. Due to the multiple special angles of the blades, regardless of the shape of the material. What is the size and density. Can mix quickly and effectively. Adopting a lower door for fast unloading speed and minimal residue.

Step 4: Equipment for manufacturing Organic fertilizer granules from cow dung. Disc granulator, Organic fertilizer agitating tooth granulator or new type agitating tooth rotating three combination granulator are used to granulate materials.

Step 5: The drum drying equipment uses a Organic fertilizer dryer to further remove moisture from the granulated particles to meet the standard requirements of Manure moisture content.

Step 6: The drum cooling equipment uses a cooling machine to cool the dried particle material, which helps to ensure the quality of particle storage.

Step 7: The screening and recycling system outputs granular materials from the granulation and forming system, which have certain differences in particle size and require screening and grading. The rotary screening machine requires low vibration, low noise, convenient screen replacement, and is equipped with a screen cleaning device. It is recommended to equip an automatic material return system to screen unqualified large and small particles, transport them out through a belt elevator, re crush them, and then send them to a granulator for further granulation, which helps to improve the continuous operation capacity of the production line.

Step 8: Granular coating equipment. The coating machine is composed of a screw conveyor, a mixing tank, an oil pump, a main engine, etc., and is used for powder or liquid coating technology. It can effectively prevent the caking of composite fertilizers. The host is equipped with a polypropylene lining or acid resistant stainless steel.

Step 9: Packaging equipment for granular material packaging, passing through the conveying equipment and entering the finished product warehouse. Granular materials are quantitatively weighed and packaged through automatic packaging scales.; The link of conveyor and Organic fertilizer production line can be configured with belt conveyor, bucket elevator or screw conveyor according to the actual needs of customers.

.jpg)

.jpg)