In material conveying scenarios requiring overcoming height differences, such as mining, port loading and unloading, and construction sites, traditional conveying equipment is often limited by the conveying angle, resulting in problems such as large footprint and low conveying efficiency. large-angle belt conveyors, as specialized equipment designed for large-angle inclined conveying, can achieve material conveying at large angles, even close to vertical (90°), effectively solving the industry pain points of high-drop conveying. It can efficiently transfer bulk materials such as coal, ore, sand, and grain, as well as some single items, becoming a core conveying equipment in industrial production for bridging height differences and optimizing site layout.

The stable and efficient operation of large-angle belt conveyors relies on targeted structural design, with each core component working in concert to ensure the stability of large-angle conveying. The inclined-angle conveyor belt is the core component of the equipment, employing a special design with corrugated sidewalls and transverse partitions—the corrugated sidewalls prevent material from slipping off the sides, while the transverse partitions divide the conveyor belt into several “hopper”-like spaces, fundamentally solving the problem of material slippage during large-angle conveying. The drive unit, consisting of a motor, reducer, and drive roller, provides sufficient traction to the conveyor belt, ensuring smooth operation even under large-angle load conditions. The redirecting roller changes the belt’s direction of travel, effectively adjusting belt tension distribution, especially during large-angle conveying operations, thus ensuring equipment stability. Idler rollers and the support frame form a support system; the idlers support the conveyor belt and reduce running resistance, while the support frame provides robust structural support for the entire device, adapting to installation requirements in complex environments. The tensioning device is crucial for large-angle conveying, ensuring the conveyor belt maintains appropriate tension during operation and preventing slippage due to excessive angle. Furthermore, the control system monitors and adjusts parameters such as conveyor speed and belt tension in real time, and, in conjunction with safety devices such as emergency stop switches and belt misalignment alarms, comprehensively ensures the safety of the equipment and operators.

The working principle of the large-angle belt conveyor is based on the synergistic effect of a dedicated conveyor belt and drive system, resulting in a clear, efficient, and reliable process. During operation, materials are first loaded onto a conveyor belt with corrugated sidewalls and transverse partitions from the lower feed inlet. The special structure of the conveyor belt firmly “locks” the material in, preventing it from scattering before inclined transport. Then, the drive unit starts, driving the conveyor belt upwards along a preset large-angle inclined path via the drive rollers. Under the combined constraint of the corrugated sidewalls and transverse partitions, the material is stably lifted with the conveyor belt, preventing slippage due to excessive inclination. When the material reaches the upper part of the conveyor belt, it is unloaded by its own gravity or a dedicated unloading device. The entire conveying process is continuous and smooth, achieving efficient material transfer from low to high.

The unique design gives the large-angle belt conveyor many core advantages, enabling it to adapt to complex high-drop conveying needs. Its large-angle conveying capacity is its most prominent highlight, achieving near-vertical conveying up to 90°, significantly shortening the conveying distance and saving considerable space, making it particularly suitable for space-constrained environments such as mines and ports. High efficiency is equally noteworthy. The specialized conveyor belt’s structural design ensures no material slippage during large-angle conveying, guaranteeing continuous and stable transport and improving overall efficiency. Its adaptability is exceptional, capable of conveying heavy bulk materials like coal and ore, as well as lightweight materials such as grain. It also adapts to complex terrain conditions such as steep mine slopes and high stockpiles in ports. In terms of operation and maintenance, the equipment’s structural design prioritizes ease of maintenance, making daily inspections and upkeep convenient and efficient. Compared to other large-angle material lifting methods, it consumes less energy and generates less noise, exhibiting excellent energy-saving and environmental performance. Comprehensive safety protection devices further enhance the equipment’s reliability, providing strong protection for industrial production safety.

From lifting ore underground in mines to stacking cargo in ports, from transferring sand and gravel at construction sites to vertical transport in grain warehouses, the large-angle belt conveyor, with its unique large-angle conveying capacity, highly efficient and stable performance, and compact structural design, provides the optimal solution for high-drop material transport in various industries. Against the backdrop of industrial production transforming towards higher efficiency and greater intensification, this equipment not only optimizes site layout and improves production efficiency, but also promotes energy-saving upgrades of conveying systems, becoming an indispensable core equipment in scenarios involving conveying across height differences.

Integrating Conveyance with Granulation in Fertilizer Production

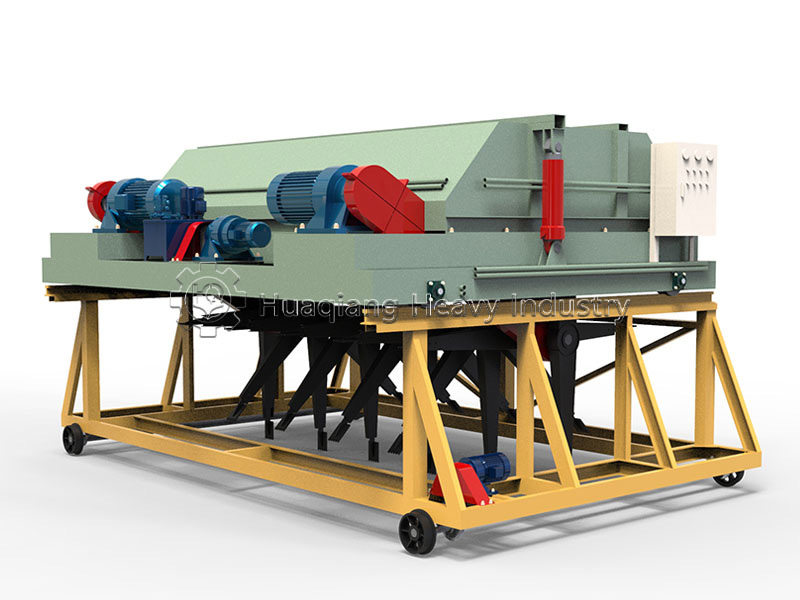

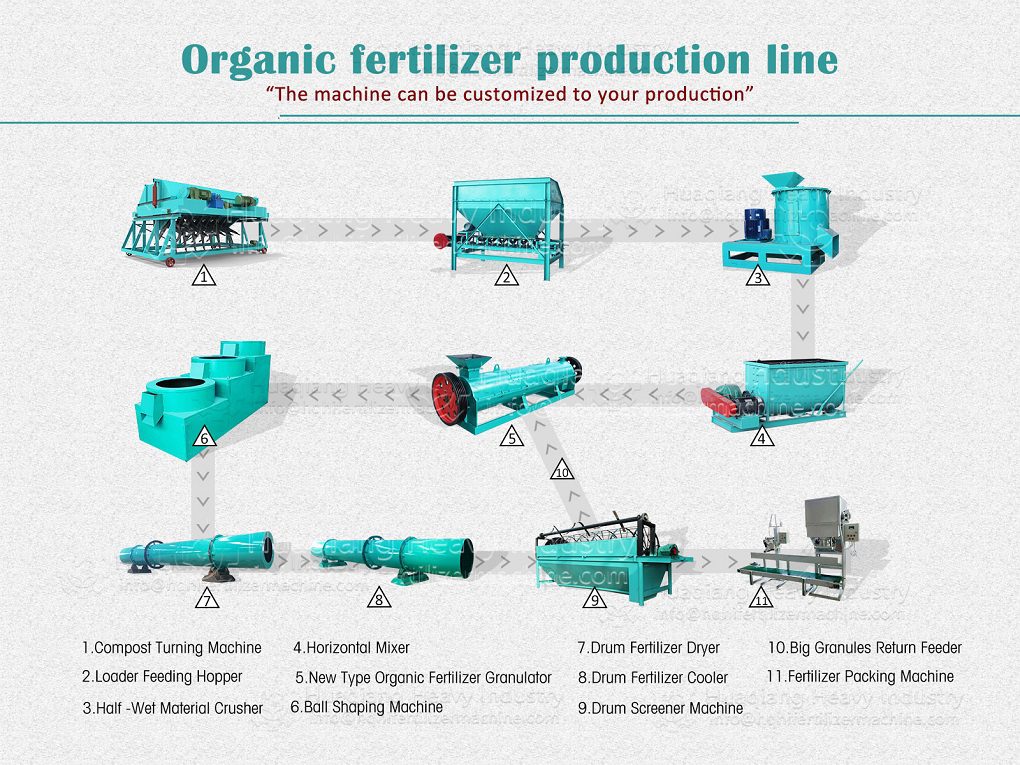

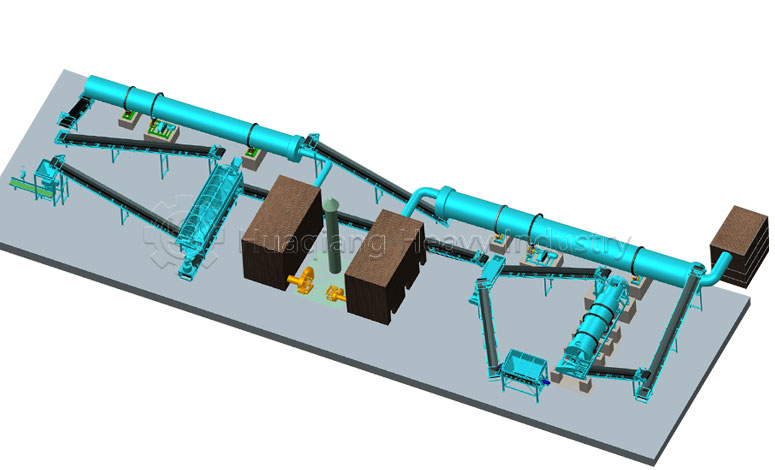

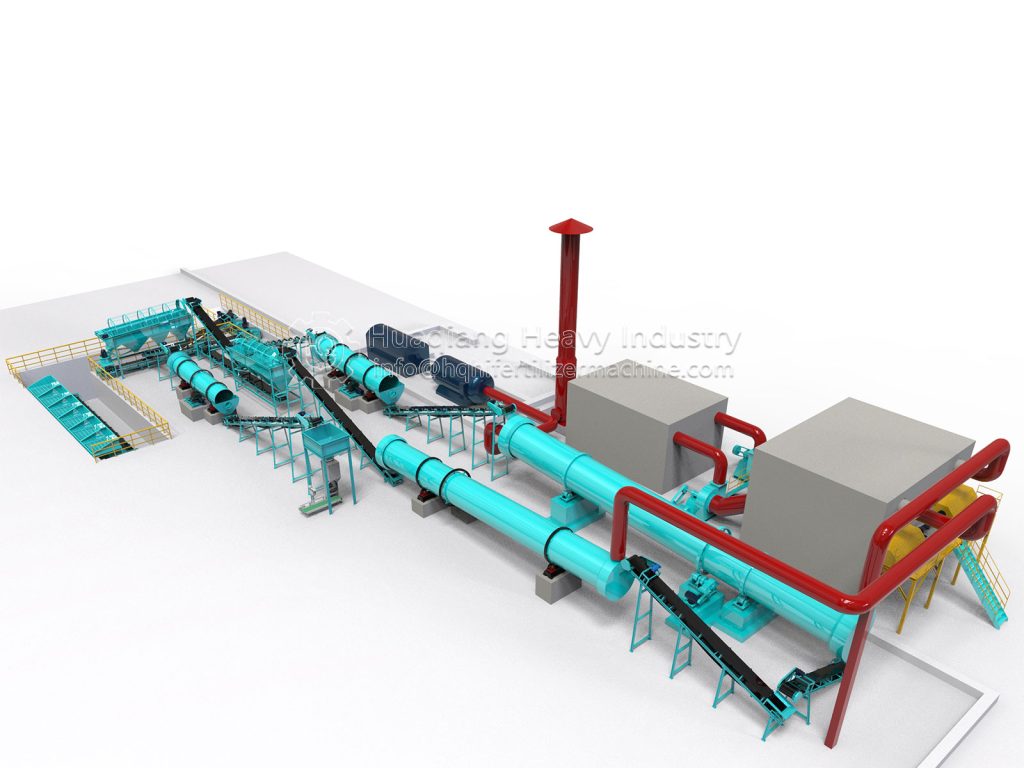

The efficient vertical transfer capability of large-angle belt conveyors is a critical component within modern professional fertilizer manufacturing equipment setups. In a fertilizer plant, these conveyors are essential fertilizer raw material processing machinery and equipment, moving bulk powders or granular materials between different process levels. For instance, in an npk fertilizer production process, a conveyor may lift blended material from a npk bulk blending machine to the feed hopper of a granulator. Similarly, in an organic line, it can transfer cured compost from a windrow composting machine to the granulation unit.

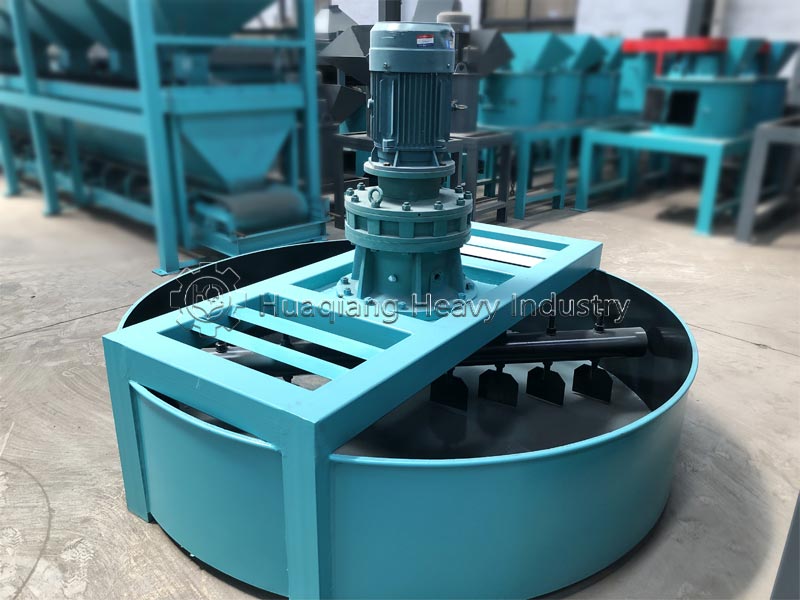

This reliable material flow is vital for feeding the core shaping equipment. The conveyed material might be directed to a disc granulator (central to a disc granulation production line), where the disc granulator for shaping forms spherical pellets via a tumbling action. Alternatively, it could feed a double roller press granulator within a roller press granulator production line for dry compaction granulation. The disc granulator machine and other granulators thus rely on seamless, high-angle conveying to maintain a continuous and efficient production line.

Therefore, the integration of robust, space-saving conveying solutions with specialized granulation technology is fundamental to designing compact, multi-level fertilizer plants that optimize both floor space and production workflow.