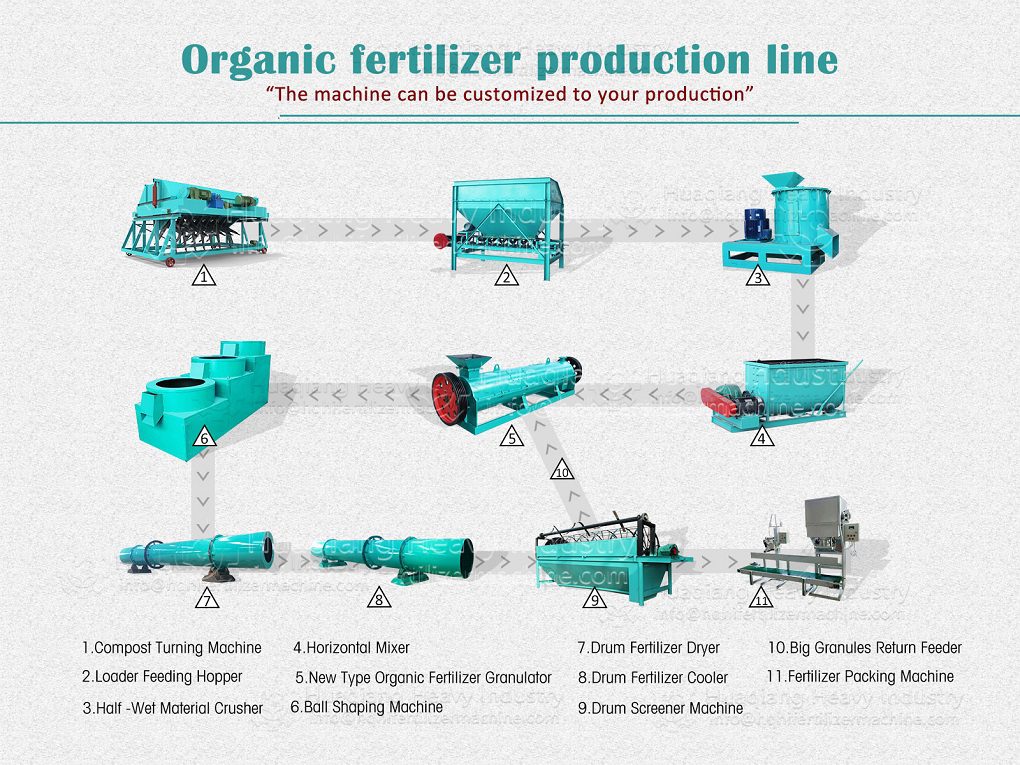

Recently, the organic fertilizer combined granulation production line built by Zhengzhou Huaqiang Heavy Industry successfully completed installation and commissioning, and officially entered large-scale production. This production line innovatively adopts a closed-loop process of “chain crushing + combined granulation + precision drying and cooling,” integrating the entire chain of raw material pretreatment, precise batching, compound granulation, and finished product post-processing. With its efficient and stable operating performance and green and environmentally friendly design concept, it provides a one-stop solution for the resource utilization of organic fertilizer, helping to turn agricultural waste into treasure.

Production Line Full Process Configuration and Core Details

Raw Material Pretreatment Unit: Laying a Solid Foundation for Clean Production

(I) Raw Material Feeding and Crushing

The production line starts with a 2×3 meter loader feeding hopper. Its large-capacity design adapts to the rapid feeding needs of bulk organic raw materials such as livestock and poultry manure, straw, and mushroom residue. The feed inlet is equipped with anti-spillage baffles and impurity filter grids, effectively removing large impurities such as stones and plastics, reducing the risk of equipment failure.

Raw materials are conveyed via a 6-meter belt conveyor to an 800-ton chain crusher. This equipment employs a high-strength chain crushing structure, with wear-resistant alloy blades that achieve a hardness of HRC58 or higher after heat treatment. It can crush large pieces of mature raw materials (particle size ≤100mm) into uniform particles ≤3mm, with a crushing efficiency of 8 tons/hour. The crushed material is then transferred to subsequent stages via a 9-meter belt conveyor. The equipment’s operating noise is controlled below 75dB, meeting industrial production noise standards.

(II) Grading, Screening, and Recycling

The crushed raw materials enter a 1.2×4.0-meter drum screen (document “12X4 meters” specification). This screen uses a single-layer high-precision mesh design, with adjustable mesh apertures to separate substandard coarse particles. Unqualified granules are returned to a 600-ton chain crusher via a 5-meter return conveyor belt for re-crushing, achieving a material utilization rate of 98% and ensuring uniform raw material fineness, thus guaranteeing subsequent batching and granulation. Qualified raw materials are systematically transferred to the batching stage via 7-meter and 9-meter conveyor belts.

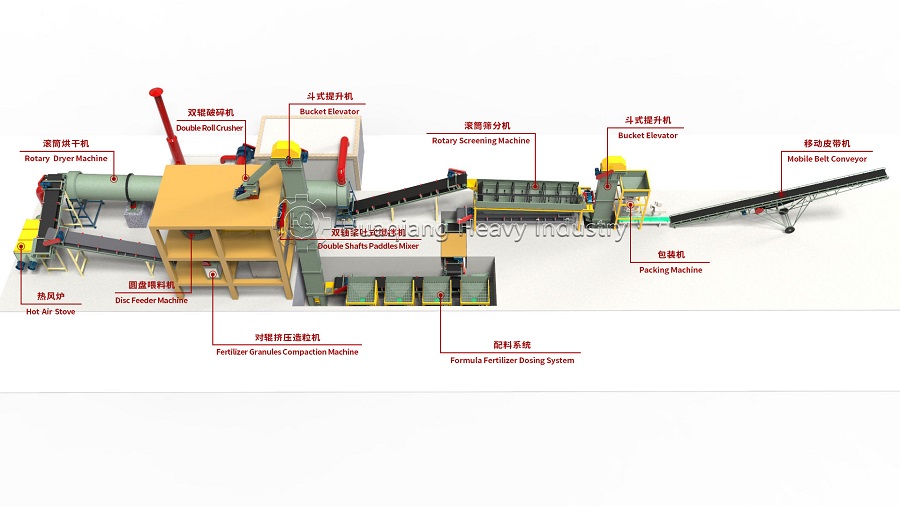

Precise Batching and Mixing Unit: Ensuring Nutrient Balance

Equipped with a 4-compartment automatic weighing and batching machine, it can separately store the crushed organic main material, straw charcoal, trace elements, and functional microbial agents. Utilizing variable frequency weighing control technology, it precisely regulates the proportions of each component, with a batching error ≤ ±1%. The organic main material accounts for ≥80%, trace elements are added at 0.1%-0.5%, and functional microbial agents at 0.3%-0.8%, ensuring balanced fertilizer nutrients and compliance with national standards for organic fertilizers.

After batching, the materials are fed into a 400 twin-shaft mixer (described in the document as “400-shaft mixer”) via 11-meter and 13-meter belt conveyors. The equipment employs a counter-rotating impeller design with a wear-resistant coating on the impeller surface. During mixing, the materials undergo strong convection and shearing motion, resulting in a mixing uniformity error of ≤2%. The mixer is equipped with a spray humidification device to precisely adjust the raw material moisture content to 30%-35%, providing suitable humidity conditions for efficient granulation.

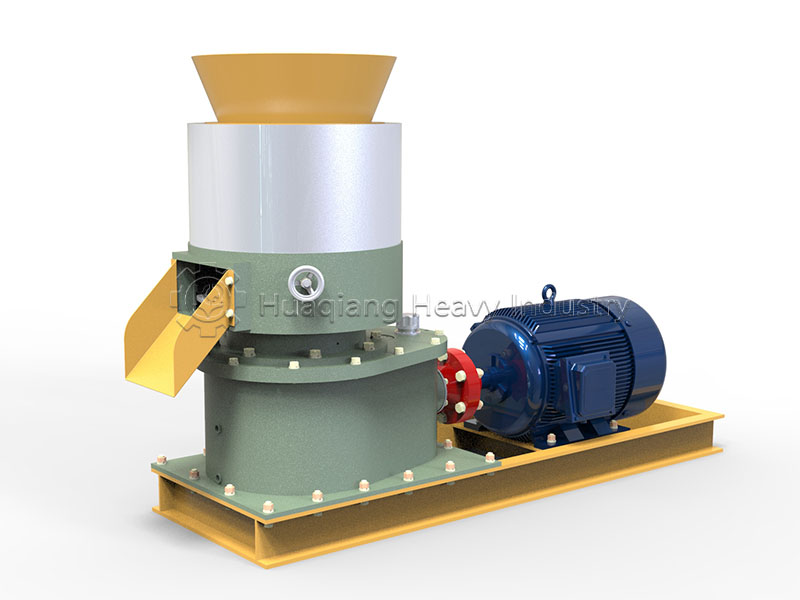

III. Core Combined Granulation Unit: Key to Efficient Molding

The mixed materials are temporarily stored in a buffer silo via a 6-meter belt conveyor, a powder feeder, and a 7-meter belt conveyor. The buffer silo stabilizes the material supply, preventing fluctuations in granulation quality due to uneven feeding. Subsequently, the materials are conveyed via an 11-meter belt conveyor to a 1000/1500 combined granulator (described in the document). This equipment is the core of the production line, integrating the advantages of two granulation modes. It adopts a “pre-compression + roll forming” composite process, suitable for organic raw materials with poor adhesion. The granulator features a built-in high-strength double-roller pre-compression device and a drum forming chamber. Loose materials are first pre-compressed into dense flakes, then shaped by the internal lifting plates and collisions within the drum, maintaining a stable granulation rate of over 90%. Particle size is uniformly controlled at 3-5mm, with a compressive strength exceeding 2.0MPa, preventing pulverization and fully meeting the needs of field application and long-distance transportation. The equipment is equipped with an automatic cleaning device to remove adhering materials from the chamber in real time, ensuring continuous operating efficiency.

Post-processing and Finished Product Output Unit: Quality Optimization and Efficient Delivery

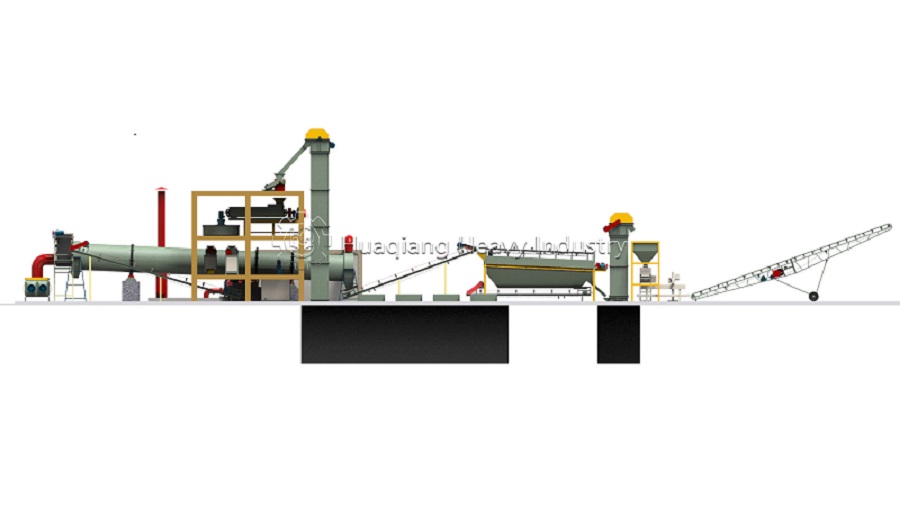

(I) Drying and Cooling Solidification

The wet granules after granulation are conveyed via a 13-meter belt conveyor to a 1.8×18-meter dryer (document “18X18 meters” is the standard term). Hot air circulation heating is used, with biomass fuel or natural gas as the heat source. The drying temperature is precisely controlled at 60-80℃ to prevent the inactivation of functional bacteria due to high temperatures. The dryer features a built-in spiral lifting plate design, ensuring uniform heating of the material and reducing the moisture content of the granules from 30% to below 12%, with a drying uniformity error of ≤2%.

The dried granules are then conveyed via 3-meter and 12-meter belt conveyors to a 1.5×15-meter cooler (standard description in document “15X15 meters”). A counter-current cooling process is employed, using ambient air to rapidly reduce the granule temperature from 70-80℃ to room temperature ±3℃, further enhancing granule strength and moisture resistance. The cooling efficiency reaches 9 tons/hour.

(II) Grading, Screening, and Finished Product Storage and Packaging

The cooled granules are then conveyed via a 13-meter belt conveyor to a 1.5×6.0-meter drum screen (standard description in document “15X6 meters”). The double-layer screen design enables precise grading, achieving a 98% pass rate for qualified granules (3-5mm). A small amount of unqualified granules are returned to the granulation front end via a 9-meter return belt conveyor for reprocessing.

Qualified granules are temporarily stored in a sealed silo equipped with dehumidification and ventilation devices to prevent moisture absorption and clumping. The packaging process utilizes an automatic granule packaging scale, supporting rapid switching between 25kg and 50kg sizes, with a measurement error ≤ ±0.2kg and a packaging speed of 100 bags/hour. Simultaneously, the production line is equipped with an automatic powder packaging scale and a dedicated finished product silo, flexibly adapting to the packaging needs of powdered organic fertilizers and achieving dual product output of granules and powders.

Environmental Protection and Auxiliary Units: Green and Stable Operation

Dust Control: Pulse dust collectors are installed in the crushing, screening, and packaging stages, with a total air volume of 15,000 m³/h and a dust collection efficiency of over 99%. The workshop dust concentration is ≤10mg/m³, meeting national environmental protection standards. Collected dust is recycled back to the production process for reuse, reducing material waste.

Intelligent Control: Key equipment on the production line is equipped with operating status monitoring devices that provide real-time feedback on parameters such as equipment speed, material temperature, and material level, facilitating timely adjustments by operators and ensuring stable production. The equipment layout is scientific, with maintenance access provided at each stage, ensuring convenient future maintenance.

Core Advantages and Application Value of the Production Line:

The combined granulation process offers significant advantages, solving industry pain points such as poor cohesion of organic raw materials and low granulation rate. The finished granules are of excellent quality and have stable fertilizer efficacy.

The entire process adopts an environmentally friendly design, with high dust recovery and utilization rates. The drying heat source is compatible with clean energy, meeting the requirements of green agriculture development and contributing to the resource utilization of agricultural waste.

The equipment configuration is compact and reasonable, with a capacity suitable for the needs of small and medium-sized organic fertilizer production enterprises. It can process various organic raw materials and is suitable for multiple scenarios such as livestock and poultry waste treatment and straw resource utilization, with broad market application prospects.

The successful implementation of this organic fertilizer combined granulation production line demonstrates Zhengzhou Huaqiang Heavy Industry’s professional strength in the research and development of complete sets of organic fertilizer equipment. In the future, the company will continue to optimize product performance, providing more customers with customized and environmentally friendly organic fertilizer production solutions, contributing to the green and sustainable development of the agricultural industry.

Building a Complete Fertilizer Production Ecosystem

This successful implementation of a combined granulation line by Huaqiang Heavy Industry underscores the importance of a fully integrated system in modern organic fertilizer manufacturing. It demonstrates how a well-designed organic fertilizer production line is not a collection of isolated machines but a coordinated ecosystem that transforms raw waste into consistent, high-value fertilizer.

The project represents a complete organic fertilizer factory solution. It begins with the crucial upstream process, where effective fermentation composting turning technology ensures the production of high-quality, mature compost. This stable organic matter is then processed through the core organic fertilizer production granulation stage. In this case, a combined granulator is used, but for different product specifications, a dedicated organic fertilizer disc granulation production line could be employed to achieve perfectly rounded granules. For producers focusing on microbial-enriched products, this entire system can be specifically adapted as a bio organic fertilizer production line, integrating the microbial inoculation stage to preserve viable beneficial bacteria throughout processing.

Ultimately, this project illustrates that the key to successful organic fertilizer production lies in seamlessly connecting each stage—from efficient fermentation and precise mixing to advanced granulation—creating a reliable and profitable operation that meets the rigorous demands of today’s agricultural market.