The large wheel turning compost machine is a pivotal fertilizer production machine for efficient aerobic composting, a core stage in biofertilizer production. Its primary advantage lies in drastically accelerating organic decomposition, creating uniform, high-quality compost. This pre-processed material is then perfectly prepared for the subsequent fertilizer compaction machine, which forms it into dense granules. Together, this compost fertilizer machine and the compactor form a seamless, efficient sequence within the complete organic fertilizer production equipment line. Their synergy ensures optimal conditions for microbial activity and granulation, maximizing the output and quality of the final biofertilizer product.

The Giant Wheel: A Silent Revolution in Composting

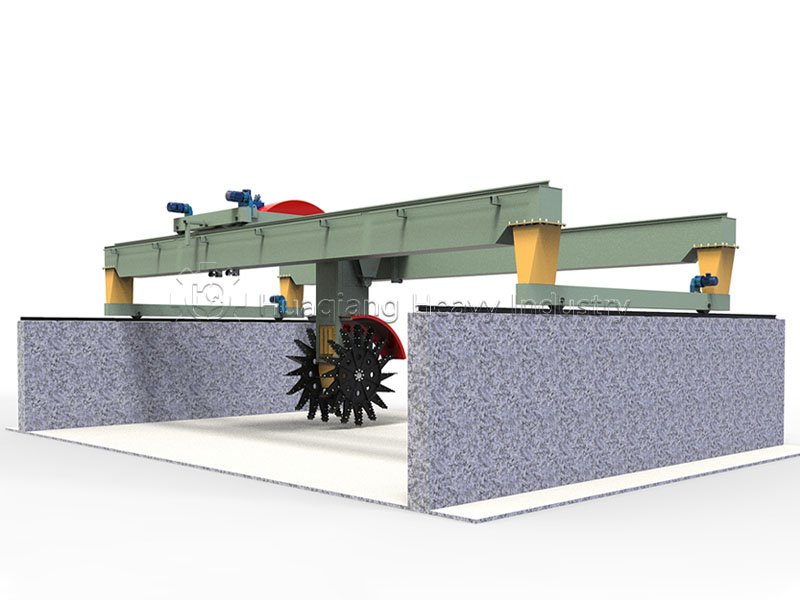

In the field of organic waste processing, an oddly-shaped machine is quietly rewriting the rules of compost production—the large wheel turner. These steel giants with diameters up to 4 meters, resembling “Ferris wheels for compost”, are pushing traditional composting technology to new heights with their unique operation.

What Makes It Special?

Unlike traditional turners, the large wheel turner’s core advantage lies in its gentle yet efficient approach. The massive wheel rotates slowly, lifting and sprinkling compost materials gently to achieve near-perfect aeration. This design prevents structural damage from material compression, making it ideal for compost containing woody materials.

Comparative studies show: composting cycles using wheel turners are 30-40% shorter than traditional methods, with oxygen penetration nearly doubled and microbial activity significantly enhanced.

Engineering Brilliance

Modern large wheel turners are mechanical engineering masterpieces. Their core component—a 3-4 meter diameter wheel—features specially designed “turning teeth” optimized through fluid dynamics to deliver optimal turning with minimal energy consumption. Automatic control systems precisely adjust rotation speed based on material conditions.

Environmental and Economic Wins

Beyond technical advantages, wheel turners offer significant environmental benefits. Their enclosed design reduces ammonia emissions by 70%, while low energy consumption cuts processing costs by over 40% per ton. For facilities handling hundreds of tons of organic waste daily, this translates to substantial savings.

As global interest in organic agriculture grows, large wheel turners are transitioning from specialty equipment to mainstream solutions. More than just machines, they’ve become vital links connecting organic waste with sustainable agriculture.