Disc granulators have always held a crucial position in granulation production in industries such as fertilizer, metallurgy, and building materials, becoming the preferred equipment for many companies. They offer numerous irreplaceable advantages.

In terms of granulation performance, disc granulators are considered “precision granulation experts.” The rotating disc drives the material in a circular motion. The combined effects of centrifugal force, gravity, and friction evenly coat the material with water or binder, resulting in a finished product with uniform size and high roundness. Compared to other granulation equipment, disc granulators produce granules with moderate strength and resistance to breakage. These granules maintain excellent condition during subsequent storage, transportation, and use, effectively improving product quality and market competitiveness.

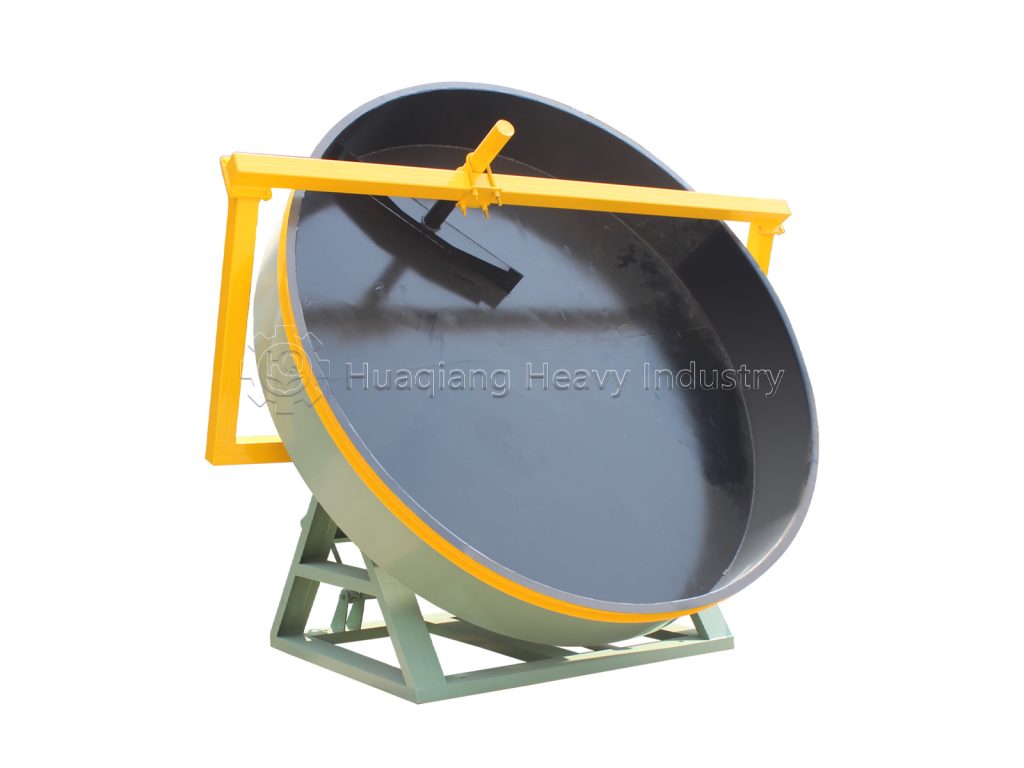

Another key advantage of disc granulators is their ease of operation. With a simple structure consisting solely of a rotating disc and transmission mechanism, routine operation requires no complex technical skills and can be mastered by workers after a short training period. Furthermore, its operation is stable, with a low failure rate. Even if minor issues do occur, repairs are relatively simple, significantly reducing downtime, ensuring continuous and efficient production, and minimizing losses caused by equipment failure.

Disc granulators also offer significant advantages in terms of cost and energy consumption. Their relatively low manufacturing cost allows small and medium-sized enterprises to install advanced granulation equipment without a high investment. Furthermore, their low energy consumption during operation significantly reduces electricity, fuel, and other energy consumption compared to other granulation equipment with the same production capacity. Long-term use can help companies reduce production costs and increase profitability.

Disc granulators are also widely applicable, effectively adapting to fertilizer production lines such as organic fertilizer and compound fertilizer, as well as granulating industrial materials such as ore powder and coal powder. This “one machine, multiple uses” feature eliminates the need for companies to purchase separate equipment for different materials, further reducing equipment investment and improving resource utilization.

With its outstanding comprehensive performance, disc granulators are an ideal choice for granulation production, helping various industries achieve high-quality and efficient granulation operations.