Animal manure typically has a moisture content of 70%-90%, making it prone to clumping and anaerobic fermentation, leading to putrefaction and making direct composting impossible. The key to fertilizer production is gradually reducing moisture and optimizing the fermentation environment. This requires a closed-loop organic fertilizer production line with specialized equipment to ensure efficiency and product quality, adapting to different processing scales.

The core of pretreatment is moisture reduction and blending equipment. A solid-liquid separator is crucial in the pretreatment stage of the organic fertilizer production line, quickly reducing the moisture content of the manure to 55%-65%, preventing anaerobic fermentation. Combined with crushing equipment for dry materials such as straw, and then mixed proportionally using mixing equipment to adjust the carbon-nitrogen ratio, a solid foundation for fermentation is laid.

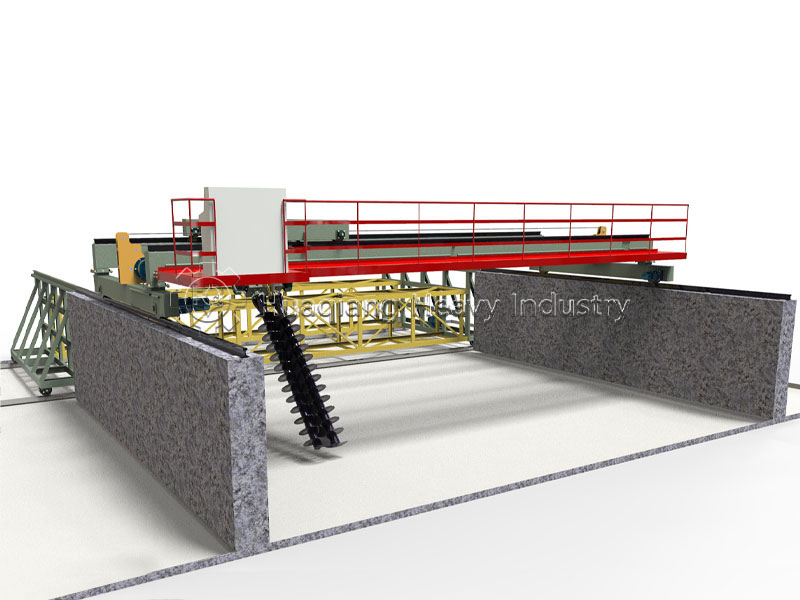

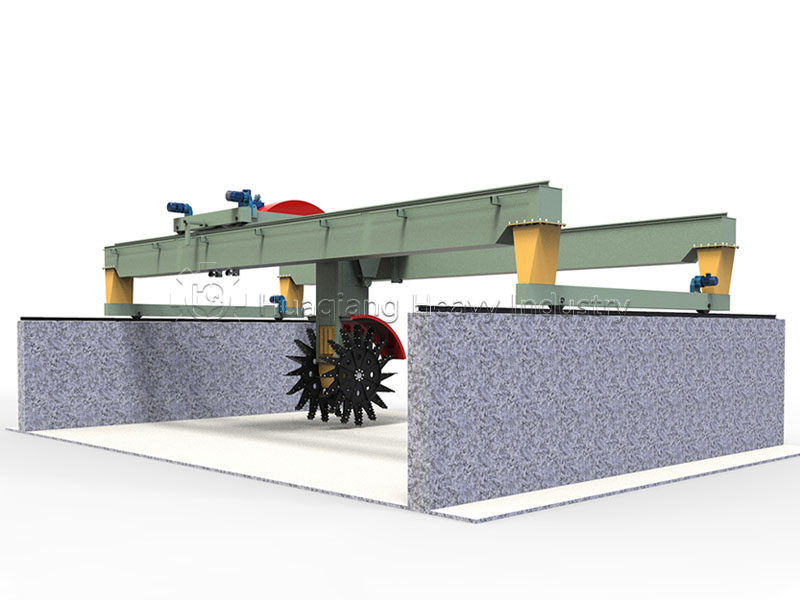

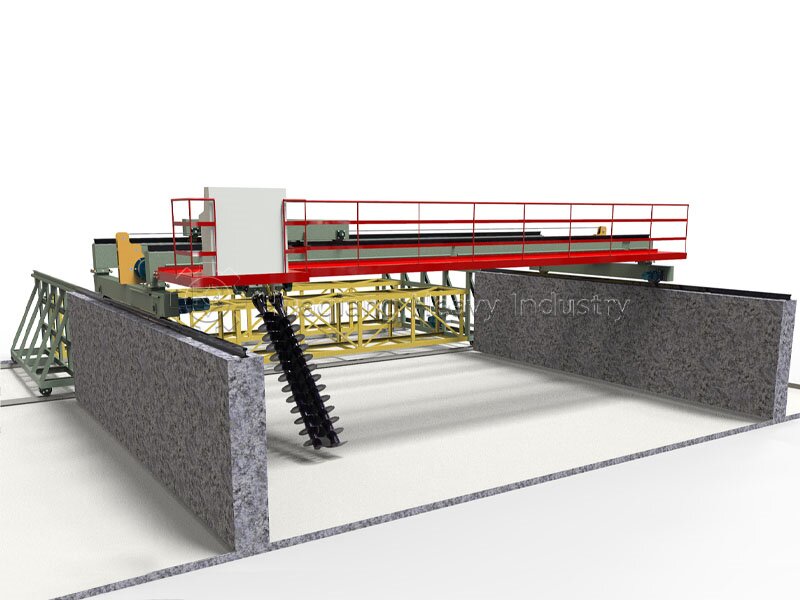

The fermentation stage requires equipment adapted to high-moisture materials. Small-scale organic fertilizer production lines can use a double screws compost turning machine to break up clumps and provide oxygen and moisture during mixing; large-scale production lines can use horizontal fermentation tanks, which provide enclosed temperature and humidity control to accelerate decomposition, reduce odor emissions, and are suitable for continuous fermentation of high-moisture materials.

Deep processing and environmental protection equipment are indispensable. If producing granular fertilizer, a fertilizer granulator is needed to process semi-dry materials; drying equipment can reduce the moisture content of the finished product, improving storage and transportation stability. Simultaneously, odor treatment equipment is necessary to prevent secondary pollution, meet environmental requirements, and complete the entire process configuration.

In summary, producing fertilizer from high-moisture animal manure requires equipment focused on “moisture reduction—fermentation—quality improvement.” The core components are the solid-liquid separator and high-moisture-adapted fermentation equipment, supplemented by deep processing and environmental protection equipment as needed, to efficiently overcome the challenges of high moisture content and produce high-quality organic fertilizer.