The cow manure organic fertilizer production line can effectively reduce the eutrophication of surface water bodies caused by pollution, solve the environmental pollution caused by breeding industries such as cattle farms and other organic wastes, and lay a foundation for human consumption of green food and organic food. A good foundation is conducive to improving the safety and quality of agricultural products, and the ecological and environmental benefits are extremely significant.

The cow manure organic fertilizer manufacturing process is using organic waste such as livestock manure to produce bio-organic fertilizer, pure organic fertilizer and organic inorganic fertilizer. The cow manure organic fertilizer equipment is characterized by fresh cow dung as raw material, after a series of processing and advanced technology, producing complete sets of production equipment of natural organic cow manure fertilizer.

The equipment is easy to operate, low in energy consumption and high in output. It adopts a new generation of high-efficiency granulation process, scientific and reasonable process, compact layout, and effectively solves the key technical problems, such as the organic raw materials are difficult to granulate of traditional granulation process, the addition amount is low, and the raw materials need to be dried and smashed treatment. The cow manure organic fertilizer equipment has stable operation, energy saving and no consumption, no three discharges, convenient maintenance, reliable operation and wide adaptability of raw materials. It can produce spherical pure organic fertilizer, organic inorganic fertilizer and biological organic fertilizer; the particles are round and uniform, smooth, good fluidity and high strength.

How to choose cow dung organic fertilizer production line equipment manufacturers? First, let us know what equipment is composed of cow dung organic fertilizer equipment?

Cow manure organic fertilizer equipment is divided into three configurations: low, medium and high:

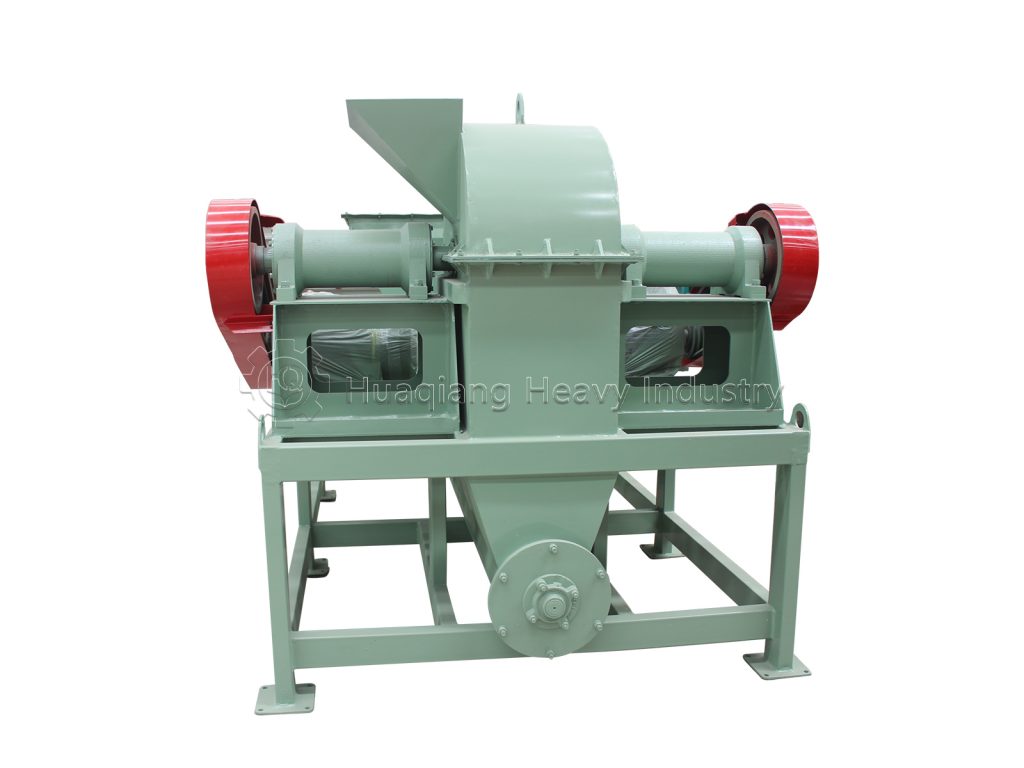

Low configuration: semi-wet material pulverizer, horizontal mixer, fertilizer granulator machine, drum sieving machine, packaging equipment.

Medium configuration: semi-wet material pulverizer, horizontal mixer, fertilizer granulator machine, dryer, cooler, drum sieving machine, packaging equipment, belt conveyor, etc.

High configuration: chicken manure dehydrator, fermentation compost turner machine, semi-wet material crusher, horizontal mixer, fertilizer granulator machine, dryer, cooler, drum sieving machine, coating machine, packaging equipment, belt conveyor, etc.

The quality of organic fertilizer equipment directly affects the level of efficiency. Therefore, when we choose the cow manure organic fertilizer machine manufacturers, we must not blindly choose, we must choose strong and responsible manufacturers. It is not easy for customers to earn every penny. It is also necessary to carefully select the equipment that is more suitable for them and find a manufacturer of organic fertilizer production lines with excellent technology and good after-sales service.

Other article for your reference:Pig manure organic fertilizer production equipment