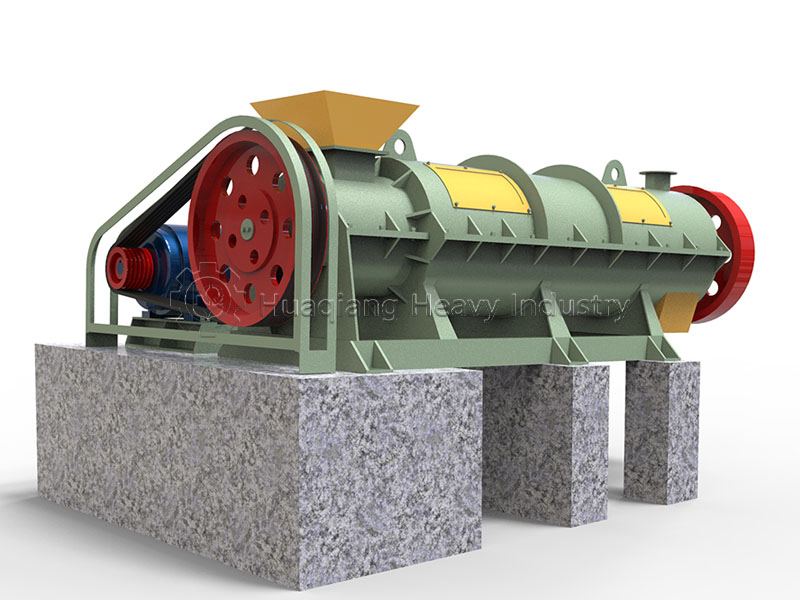

Fiber raw materials such as straw, mushroom residue, and rice husks are common components in organic fertilizer production. However, these materials are prone to fiber entanglement with the rollers during pelletizing, leading to equipment stalls and a sharp drop in pelletizing efficiency. The flat die granulator, with its targeted structural design, is an ideal solution for this problem.

The core cause of fiber entanglement is insufficient cleavage of long fibers in the raw material, or a smooth roller surface that causes fibers to entangle as the rollers rotate. The flat die granulator’s design addresses this problem by focusing on two key points: First, the flat die holes feature a “deep straight hole” layout (15-20mm depth). This shortens the vertical force path when the fiber raw material is squeezed into the hole, reducing the fiber’s residence time between the rollers and the flat die.

Second, a pre-crushing pretreatment is recommended, with the fiber raw material pulverized to 0.5-1mm to ensure that long fibers are cut, thus reducing the likelihood of entanglement at the source.

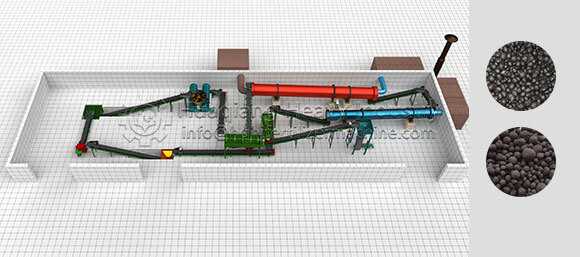

In actual production, if slight entanglement still occurs, the gap between the roller and the flat die can be adjusted to maintain 0.2-0.3mm, or 1%-2% bentonite can be added to the raw materials for further optimization. This solution can increase the smoothness of granulation of fiber raw materials to over 90%, avoiding frequent downtime for cleaning and ensuring stable operation of the organic fertilizer production line.