The core quality indicator of BB fertilizer (blended fertilizer) is nutrient uniformity, and the mixing performance of the BB fertilizer mixer directly determines the quality of the final product. This process is influenced by several key factors and requires targeted control.

First, the raw material pretreatment stage. BB fertilizer raw materials are mostly nitrogen, phosphorus, and potassium single granular fertilizers or powdered organic fertilizers. If the raw material particle size varies greatly, stratification due to different densities is likely to occur. Screening is required to control the raw material particle size deviation to within 2mm. At the same time, the raw material moisture content must be maintained at a stable 12%-15%. Too high a moisture content can easily cause the particles to stick together, while too low a moisture content can cause the powdered raw material to generate dust.

Second, the mixing parameter setting is important. The speed of the BB fertilizer mixer should be adjusted according to the raw material type. When mixing granular fertilizer, the speed can be set to 15-20 rpm to avoid particle collision and breakage caused by high speed. When mixing raw materials containing powder, the speed can be increased to 20-25 rpm. The mixing time also needs to be controlled. Typically, 8-12 minutes per mixing cycle is sufficient. Too short a time will result in uneven mixing, while too long a time can easily cause excessive friction and loss of the raw materials.

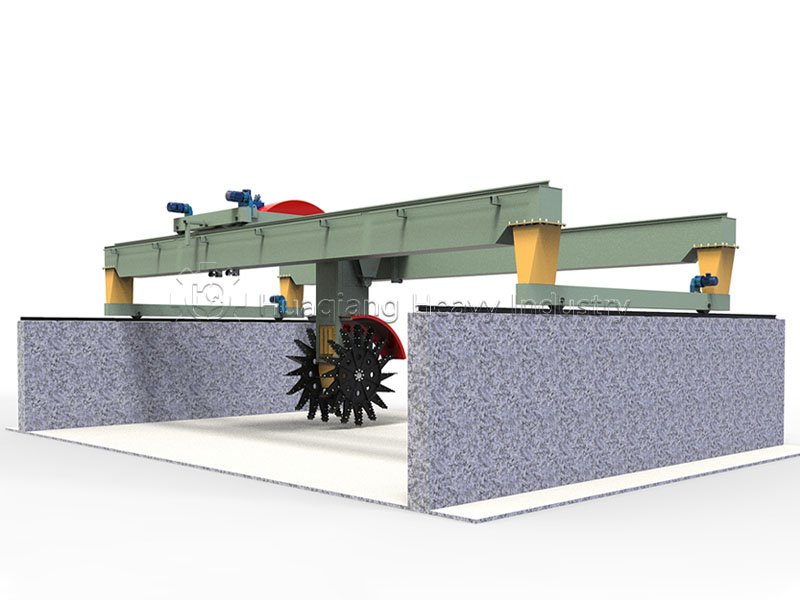

Finally, the compatibility of the equipment structure is important. The impeller design of the BB fertilizer mixer must balance convection and shearing. If the raw materials contain a small amount of fiber (such as when adding straw powder to organic fertilizer), impellers with scraping functions should be used to prevent the raw materials from adhering to the cylinder walls. The cylinder should avoid right angles and instead use rounded transitions to reduce dead corners where raw materials accumulate, ensuring that every portion of the raw materials is mixed and ensuring uniformity from a structural perspective.