In modern fertilizer production, granulators perform a crucial transformation—transforming uniformly mixed powdery raw materials into neat, solid granules.

For production companies, the most direct change brought about by granulation is the optimization of physical properties. Granular fertilizers have better flowability, greatly improving the efficiency of packaging, transportation, and mechanized application. Whether on NPK fertilizer production lines or organic fertilizer production lines, this improvement in physical properties directly translates into economic benefits.

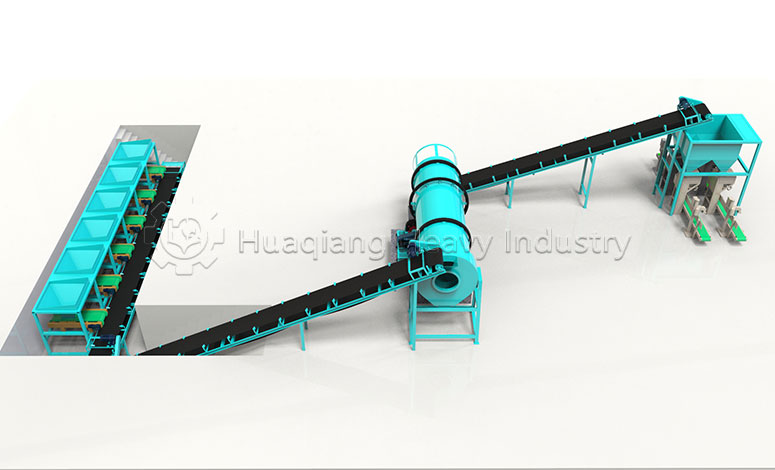

From an equipment application perspective, while specialized organic fertilizer granulators and chemical fertilizer granulation equipment have different technological focuses, their core objective is the same: to lay the foundation for subsequent processes by shaping ideal granules. In a complete organic fertilizer production line, the granulation process is often the core link between fermentation and composting and finished product packaging.

From an agronomical perspective, the uniform granule shape creates conditions for precision fertilization. On NPK fertilizer production lines, each finished product carries a precisely proportioned nutrient solution; while on organic fertilizer production lines, granules become the ideal carrier of organic matter and functional microbial communities. This consistency in form allows for more controllable nutrient release and more coordinated crop absorption.

This equipment, connecting raw materials and finished products, has become a core component of both NPK fertilizer production lines and organic fertilizer production lines. By reshaping fertilizer form, it not only enhances product competitiveness but also establishes an indispensable industry position in the trend of agricultural mechanization and precision.