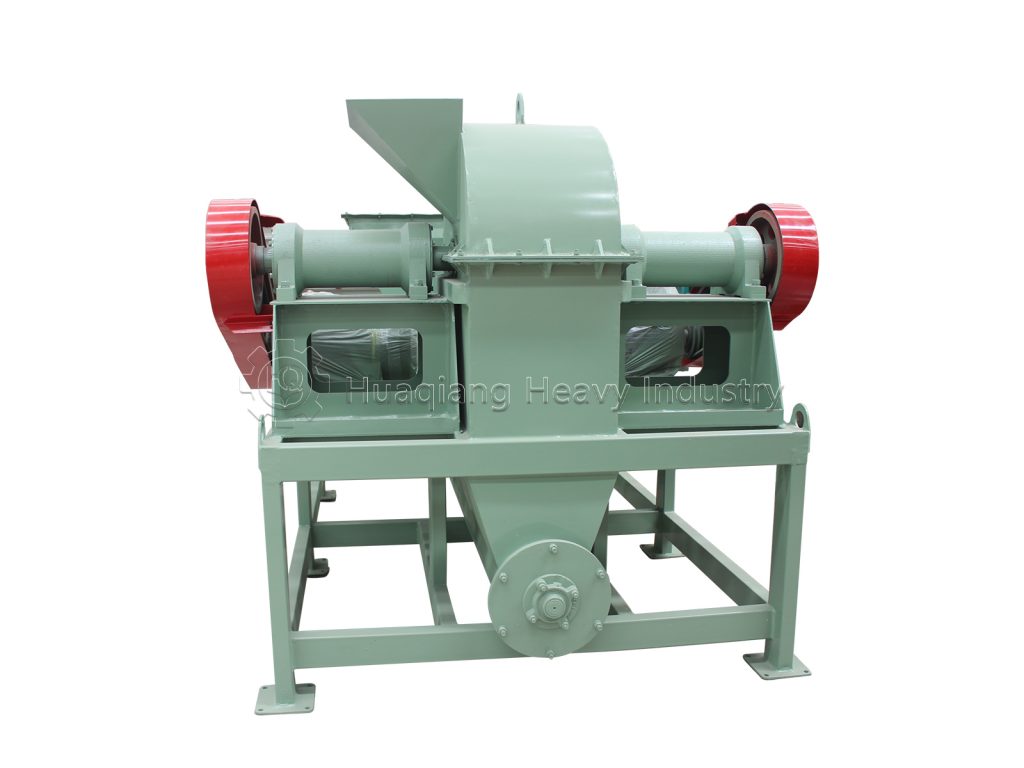

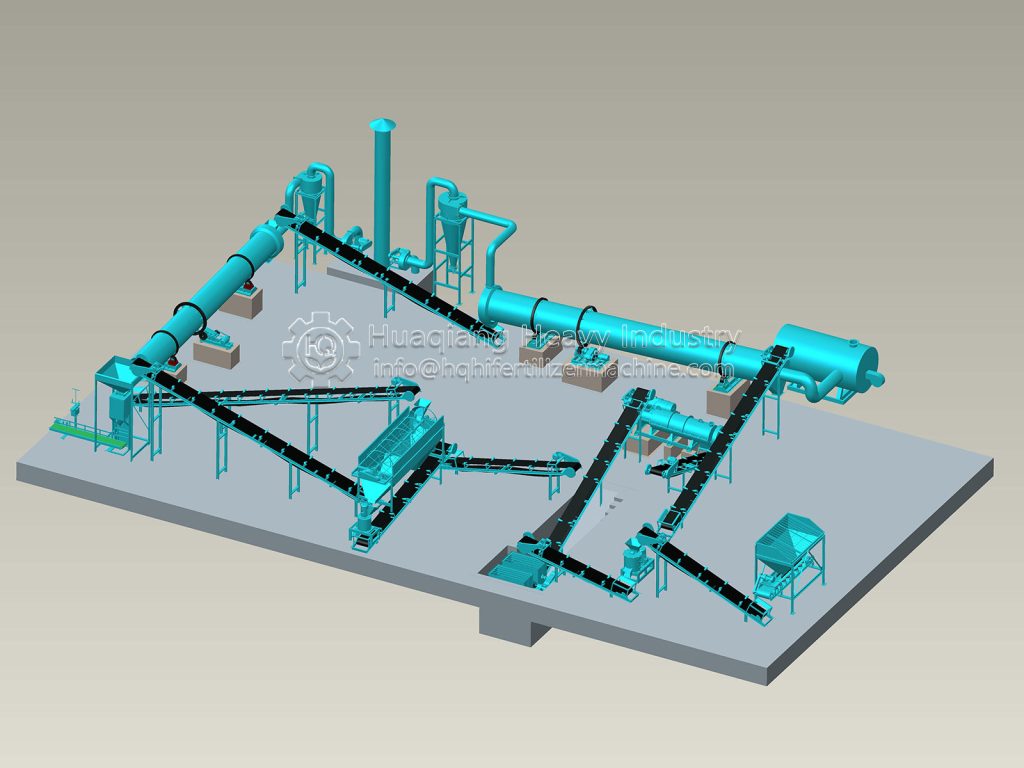

The new type two-in-one organic fertilizer granulator features an integrated “mixing + granulation” design, simplifying organic fertilizer production. Its operations are centered around four core steps, ensuring pellet quality and efficiently supporting the organic fertilizer production line.

The first step is raw material pretreatment. Fermented organic fertilizer (such as livestock manure and composted straw) must first be crushed to a 40-60 mesh fine powder with a moisture content of 25%-35%. Excessively coarse raw materials will result in uneven granulation, while inappropriate moisture content will affect the final product. Meeting pretreatment standards is essential for stable equipment operation.

The second step is the core mixing process. Pretreated raw materials enter the integrated mixing system. A high-strength alloy steel agitator shaft drives the wear-resistant blades, while a variable frequency motor precisely controls the speed between 20-60 rpm. If binders such as bentonite are required, they are added simultaneously. The blades shear and stir the powder, achieving over 90% mixing uniformity within 5-10 minutes, preventing uneven nutrient distribution in the pellets.

The third step is targeted granulation. The mixed material automatically enters the granulation system, where the equipment changes its forming method based on the raw material’s characteristics. Highly viscous raw materials (such as chicken manure organic fertilizer) use a stirring granulation mechanism, where paddles knead the material into 2-4mm pellets. High-fiber raw materials (such as straw organic fertilizer) use a roller-type granulation mechanism, where die extrusion forms the pellets. The stainless steel disc can be hydraulically adjusted from a 30° to 50° tilt angle, and a wear-resistant rubber lining reduces sticking to the wall. The pellet formation rate exceeds 90%, and the pellets are uniformly shaped.

Finally, the screen residue is recycled and connected. After granulation, the pellets pass through an integrated screening device. Qualified pellets enter the drying stage (dried to a moisture content of less than 10%), while substandard fines are returned to the mixing system through a recirculation channel for processing with new raw materials. This design achieves a raw material utilization rate exceeding 95%, reducing waste and ensuring continuous production.

The entire process eliminates the need for frequent manual handling. The new type two-in-one organic fertilizer granulator can complete the entire process from raw material input to qualified pellet output, significantly improving the efficiency and convenience of organic fertilizer production.