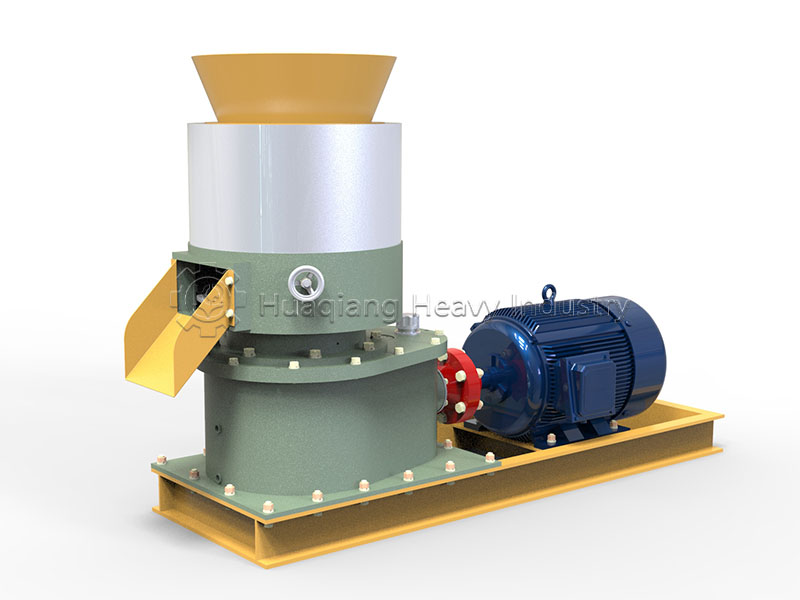

In the field of material pulverization, cage crushers, with their unique performance advantages, have become an ideal choice for many manufacturers and occupy a key position among various types of pulverizers.

In terms of compatibility, cage crushers are excellent for processing low- to medium-hardness materials, particularly those with a Mohs hardness of 1.0-2.0. Materials with a hardness exceeding 3 are less suitable due to excessive wear on the cage.

In terms of pulverization performance, cage crushers offer excellent fineness control. By precisely controlling the screen aperture, fineness can be adjusted from 0.2 to 5.0 mm. The high precision of the screen aperture guarantees a 90% particle size deviation of ≤0.2 mm.

In terms of uniformity, the unique synergistic effect of impact and grinding produces a narrow particle size distribution. For example, when crushing corn, 80% of the particles are concentrated between 0.8 and 1.2 mm, resulting in minimal over-fine grinding. Material loss is low, sealing performance is excellent, and the dust rate is only 3% to 5%.

Energy consumption and maintenance are also important indicators of crusher performance. The specific energy consumption of a cage crusher is moderate. For example, when crushing corn, the energy consumption ranges from 8.5 to 15.6 kW h/t, but energy consumption increases with finer grain size. The lifespan of its wearing parts is relatively long.

Regarding maintenance, while regular cleaning of the screen and cage residue is required, and cage replacement requires complete machine disassembly, overall, the maintenance effort and cost are relatively moderate.

With its comprehensive advantages in material compatibility, crushing efficiency, energy consumption, and maintenance, cage crushers demonstrate strong competitiveness in applications requiring medium-to-fine crushing of low- to medium-hardness materials, with high requirements for crushing accuracy and particle shape.

.jpg)