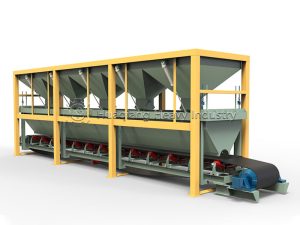

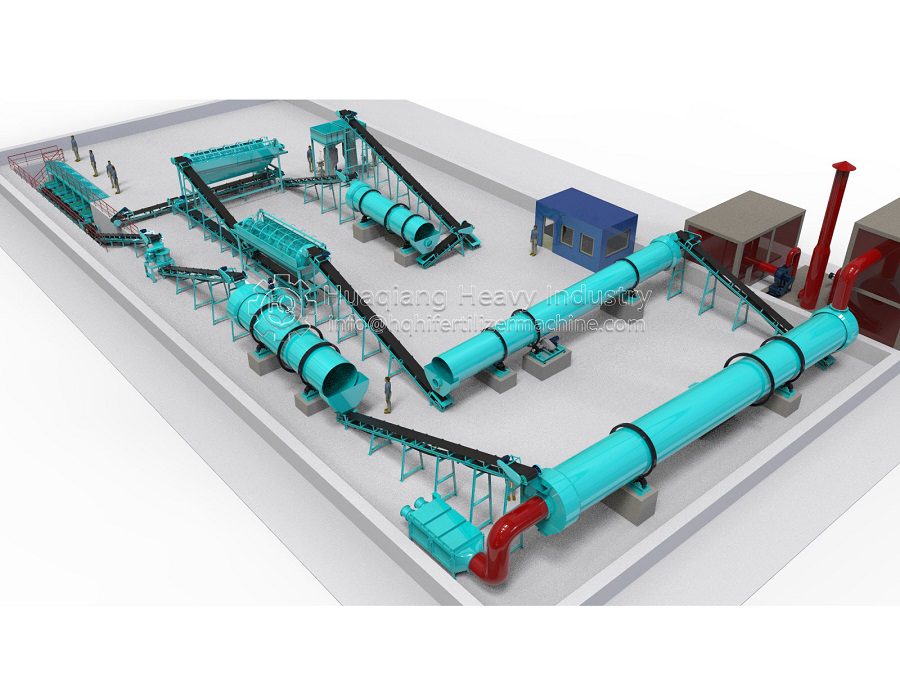

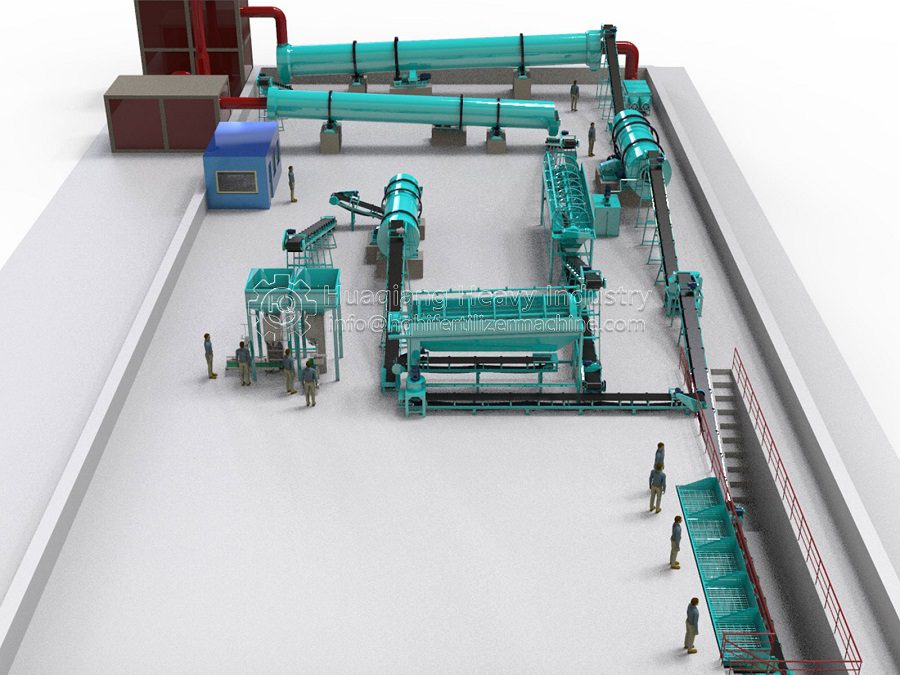

The core advantages of the 5-Warehouse Receipt Scale Static Batching + Drum Granulation Production Line are precise batching and smooth granulation. It is specifically designed for large-scale fertilizer production requiring strict control of nutrient ratios and high granule quality. It also has clear adaptation standards for raw material characteristics to ensure production efficiency and product stability.

Suitable Fertilizer Types

(I) Core Compatible Fertilizers

NPK Compound Fertilizer (General/Specialized): It can flexibly produce multi-ratio compound fertilizers such as 15-15-15 general-purpose and 16-8-20 high-potassium types. The 5 warehouses can separately store main raw materials such as urea, monoammonium phosphate, and potassium chloride, as well as trace elements zinc and boron. The static batching error per scale is ≤±1%, meeting the nutrient requirements of different crops. Drum granulation forms 3-5mm spherical granules with good flowability and a strength of over 2.5MPa, making them resistant to storage and transportation and easy for mechanized fertilization.

Organic-Inorganic Compound Fertilizer: Suitable for mixing and granulating fermented livestock and poultry manure, straw charcoal, and other organic raw materials (20%-50%) with inorganic fertilizers. Five independent storage compartments prevent raw material reactions. Static batching precisely controls the organic-inorganic ratio, and drum tumbling ensures full material integration, enhancing slow-release performance.

Slow-Release/Functional Compound Fertilizer: Can produce slow-release fertilizers with added urea-formaldehyde resin and sulfur (2%-8%), or functional fertilizers containing humic acid and amino acids. Five separate storage compartments for sensitive components prevent deactivation, ensuring long-lasting effectiveness and specificity.

(II) Incompatible Fertilizers: High moisture content (>40%) raw material fertilizers, pure powder fertilizers, and ultra-high concentration fertilizers (total nutrient content >60%) can easily lead to batching blockage, low granulation rate, or uneven granules. II. Precautions for Raw Material Use

(I) Physical Property Requirements

Moisture: Inorganic raw materials should have a moisture content ≤5%, and organic raw materials 25%-35%. Excessive moisture content can lead to clumping, while insufficient moisture content results in inadequate binding.

Particle Size: All raw materials should be crushed to ≤3mm, with over 80% having a particle size of 0.1-2mm to ensure effective mixing and granulation.

Flowability: The angle of repose of raw materials should be ≤32°. Hygroscopic raw materials require dehumidification storage. For materials with poor flowability, 0.1%-0.3% anti-caking agent can be added.

(II) Chemical Property Requirements

Avoid Reaction Conflicts: Acidic and alkaline raw materials should be stored separately and quickly fed into the drum after batching to prevent nutrient loss.

Heat Sensitivity Protection: Heat-sensitive raw materials such as amino acids should be added later, with the drum temperature controlled at 60-80℃.

Prevent Cross-Contamination: Chlorine-containing raw materials and fruit and vegetable fertilizers should be produced separately to avoid affecting crop growth. (III) Ingredient and Storage Specifications

Proportion Control: Main raw materials ≥70%, auxiliary materials ≤30%, binder addition 2%-5%.

Raw Material Pretreatment: Organic raw materials must be fully decomposed (decomposition degree ≥85%) and impurities removed; slow-release agents must be pulverized to ≤0.5mm.

Storage and Transportation: Raw material silos must be sealed, rainproof, and moisture-proof, with separate silo markings; silo cone angle ≥60° to prevent bridging; sealed conveying equipment must be used; corrosive raw materials must be made of stainless steel.

Complementary Systems for Organic and Biofertilizer Production

While the 5-Warehouse Static Batching + Drum Granulation line excels with inorganic blends, a complete organic fertilizer manufacturing system often requires a different approach. For pure organic or high-organic-content fertilizers, the production typically starts with advanced fermentation composting turning technology, employing equipment such as a large wheel compost turning machine or a chain compost turning machine to produce stable, decomposed compost. This compost then feeds a dedicated organic fertilizer production line. The granulation stage offers flexibility: a traditional organic fertilizer disc granulation production line uses a pan to form spherical granules, while a drum granulation production line can also be adapted for organic materials. For smaller-scale operations, a new type two in one organic fertilizer granulator that mixes and granulates efficiently may be ideal.

This entire process of organic fertilizer production granulation is central to modern organic fertilizer manufacturing. When the goal is to incorporate beneficial microbes, the system evolves into a sophisticated bio organic fertilizer production line. Here, the granulation technology must be carefully selected to preserve microbial viability, often favoring gentle agitation granulation in a drum or disc over high-pressure methods. The key is matching the granulation technology to the physical and biological characteristics of the organic feedstock.

Ultimately, whether producing inorganic NPK blends or organic soil amendments, the principle remains: selecting the right batching and granulation technology—be it precision static batching for compounds or specialized fermentation and granulation for organics—is fundamental to achieving high-quality, market-ready fertilizer products.