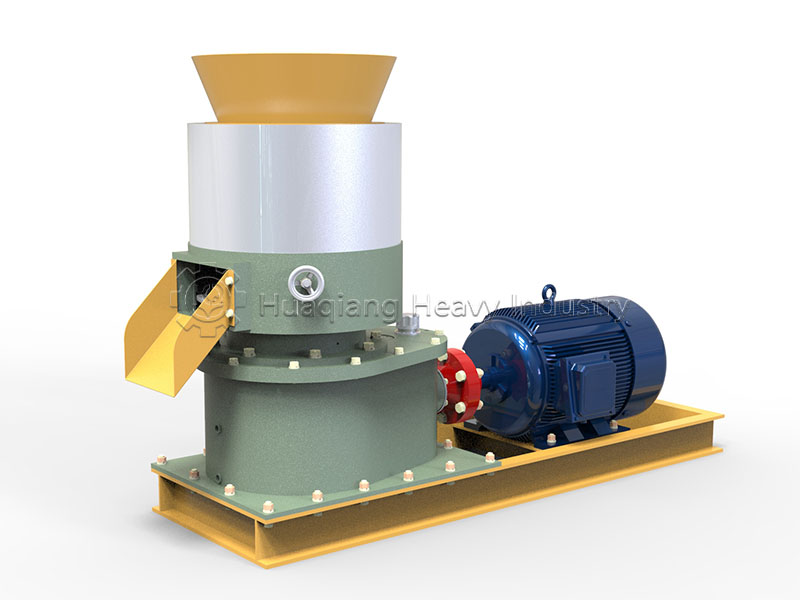

One Machine, Infinite Possibilities – Exploring How Flat Die Pelleting Machines Serve Four Core Industries

Multi-functional Granulation Solutions

In today’s industrial manufacturing landscape, the versatile fertilizer granulator has become indispensable equipment in numerous industries due to its exceptional adaptability. This technology demonstrates remarkable capabilities across multiple fields, particularly within the organic fertilizer production line and npk production line, transforming various raw materials into uniformly sized, high-quality pellet products.

The machinery family includes specialized variants like the organic fertilizer granulator for biological materials and the npk fertilizer granulator for chemical compounds. Different granulation technologies such as the double roller press granulator for compaction methods and the rotary drum granulator for agglomeration processes each bring unique advantages to production lines. These sophisticated granulation systems work synergistically within complete fertilizer production setups, ensuring optimal material transformation through their complementary technical principles and operational characteristics.

Biomass Fuel Sector

Specializes in processing biomass materials such as sawdust, straw, rice husks, and peanut shells, converting these agricultural wastes into high-calorific biomass pellet fuels. This green energy not only addresses waste disposal challenges but also provides crucial support for renewable energy development.

Feed Industry Applications

Provides ideal pelleting solutions for poultry, livestock, and aquatic feed production. By precisely controlling particle size and density, it significantly improves feed palatability and nutritional value while reducing losses during transportation and storage.

Chemical Raw Material Processing

Widely used in pelleting chemical raw materials such as fertilizers, catalysts, and additives. Ensures uniformity and stability of chemicals, improves product usage efficiency and safety, and meets strict industrial standards.

Pharmaceutical Industry Pre-treatment

Plays a crucial role in the pre-treatment process of tablet and capsule filling materials. Ensures uniform distribution of drug components through precision granulation, creating ideal conditions for subsequent tableting and packaging processes.

Technological Innovation and Industrial Value

The true advantage of flat die pelleting machines lies in their outstanding adaptability and stability. Whether processing biomass materials of varying densities or handling complex chemical raw materials, this equipment maintains stable pelleting performance. Its unique working principle ensures particle uniformity and consistency, while the modular design concept makes equipment maintenance and mold replacement exceptionally convenient. More importantly, flat die pelleting machines significantly improve raw material utilization rates while substantially reducing energy consumption, truly achieving both economic and environmental benefits.

A Key Force Driving Industrial Upgrading

As global emphasis on sustainable development continues to grow, the importance of flat die pelleting machines in the circular economy and green manufacturing sectors becomes increasingly prominent. In the biomass energy sector, they convert agricultural waste into clean energy; in the feed industry, they enhance the utilization efficiency of animal nutrition; in the chemical and pharmaceutical fields, they ensure product quality and safety. This multi-functional pelleting equipment not only solves production challenges across various industries but also makes significant contributions to efficient resource utilization and environmental protection. Looking ahead, with continuous technological advancement and ongoing expansion of application fields, flat die pelleting machines are destined to play an even more important role in global industrial upgrading and sustainable development processes.

Flat Die Pelleting Machine – Driving Multi-industry Development Through Technological Innovation, Creating Infinite Possibilities