As the global focus on sustainable agriculture intensifies, organic fertilizer production has gained unprecedented attention, and granulation stands as a pivotal link in this process. Granulation transforms loose, powdery organic compost—derived from agricultural waste, livestock manure, and biodegradable materials—into uniform granules. This critical step not only enhances the practicality and storage stability of organic fertilizers but also optimizes nutrient release, laying a solid foundation for eco-friendly farming and soil health improvement. With diverse technologies adapting to different production scales, granulation has become a core driver in upgrading the organic fertilizer industry.

The granulation process is tailored to the characteristics of organic materials, which are often low in cohesion and high in moisture. Unlike chemical fertilizers, organic fertilizer granulation requires balancing material viscosity, moisture content, and nutrient preservation to ensure granule strength and uniformity. The pre-treatment stage is essential: fermented compost is crushed, screened, and adjusted for moisture (typically 20%-30%) to meet granulation requirements. Impurities such as stones and large particles are removed to protect equipment and improve product quality, making pre-treatment a prerequisite for smooth granulation.

Various granulation technologies cater to different production needs, with three mainstream methods dominating the industry. The disc granulator, a cost-effective option for small to medium-scale facilities, uses a rotating disc to agglomerate materials into granules under the action of binding agents (such as molasses or bentonite). Its simple structure, easy operation, and low energy consumption make it widely adopted by family farms and local fertilizer plants.

For large-scale industrial production, extrusion granulators are preferred. They press mixed materials through molds under high pressure to form cylindrical granules, eliminating the need for drying and reducing energy consumption. This technology excels in handling high-fiber organic materials and ensures consistent granule density, suitable for large agricultural enterprises and commercial fertilizer manufacturers. Meanwhile, drum granulators, which combine mixing, granulation, and drying in one drum, offer high production efficiency and uniform product size, ideal for large-batch production lines.

Post-granulation processing is equally crucial to ensure product quality. Granules undergo drying to reduce moisture content to below 10%, preventing caking and mold growth during storage. Cooling stabilizes the granules’ structure, while screening separates unqualified particles for reprocessing, ensuring uniform particle size. Coating technology can also be applied to slow nutrient release, extending the fertilizer’s effectiveness and reducing nutrient loss.

Granulated organic fertilizers offer numerous advantages over powdery counterparts. Their uniform size facilitates mechanical application, improving spreading accuracy and reducing labor intensity. The dense structure minimizes nutrient leaching and volatilization, enhancing fertilizer utilization rate. Additionally, granulation inhibits odor emission and reduces dust pollution, aligning with environmental protection standards. For soil health, granulated organic fertilizers gradually decompose, releasing nutrients and improving soil structure, fertility, and water retention capacity.

Organic fertilizer production granulation is more than a processing step—it is a bridge between organic waste recycling and sustainable agriculture. By upgrading the quality and usability of organic fertilizers, it promotes the circular economy in agriculture, reduces chemical fertilizer dependence, and safeguards ecological balance. As technology advances, granulation will continue to evolve toward higher efficiency, lower energy consumption, and smarter operation, fueling the development of a greener agricultural future.

System Integration: From Composting to Granulation

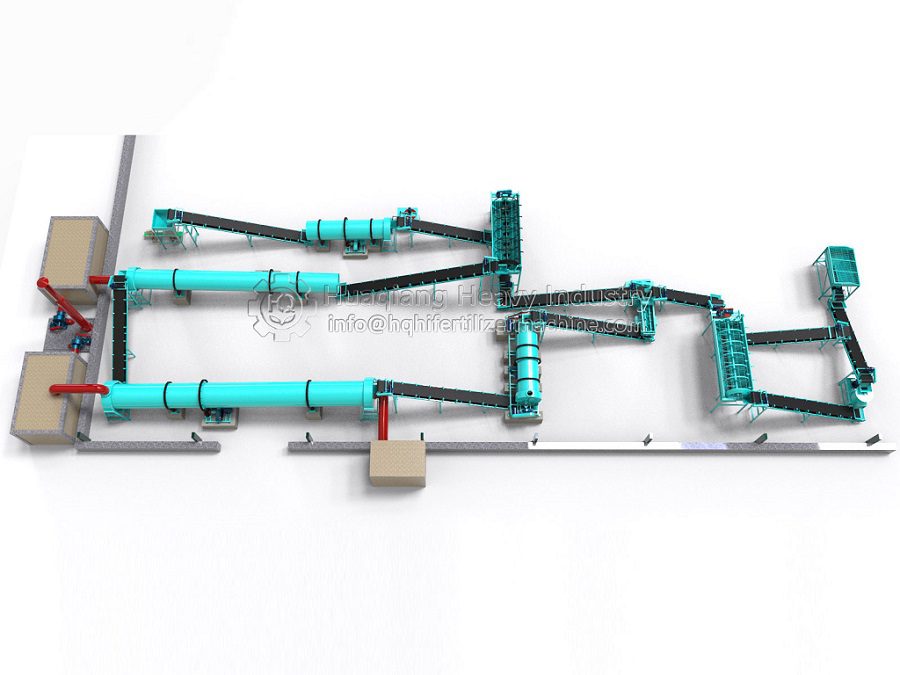

To realize this complete value chain, an integrated organic fertilizer manufacturing system is required. This system begins with efficient aerobic fermentation, often managed by equipment like a large wheel compost turning machine for windrows or a chain compost turning machine for thorough mixing. The cured compost then feeds a dedicated organic fertilizer production line. For granulation, multiple technologies are available. A traditional and effective method is the organic fertilizer disc granulation production line, which forms spherical pellets via a tumbling pan.

For operations seeking space efficiency, a new type two in one organic fertilizer granulator that combines mixing and granulation is an innovative solution. For producing dense, cylindrical pellets, a flat die press pellet machine for sale offers a robust extrusion option. When the process is designed to incorporate specific beneficial microbes post-fermentation, the system evolves into a sophisticated bio organic fertilizer production line, where gentle granulation is critical to preserving microbial viability.

This holistic approach ensures that organic waste is systematically transformed into a standardized, easy-to-apply product. The seamless connection between composting, processing, and granulation technologies is what enables the large-scale, commercial production of high-quality organic fertilizers that support sustainable soil management.