In July 2025, Zhengzhou Huaqiang Heavy Industry Technology Co., Ltd. successfully completed the installation and commissioning of a 30,000-ton-per-year organic fertilizer production line tailored for a client in Gao County, Sichuan Province, officially entering the large-scale production stage. This production line integrates the entire chain of core processes, including raw material pretreatment, crushing, screening, mixing, granulation, drying, coating, and packaging. It simultaneously covers both granular and powdered organic fertilizer product lines. With its highly automated configuration, environmentally friendly and energy-saving design, and optimized adaptability to the characteristics of raw materials in Southwest China, it has become a benchmark project for organic fertilizer production equipment in southern Sichuan, injecting strong momentum into the resource utilization of local agricultural waste and the development of green agriculture.

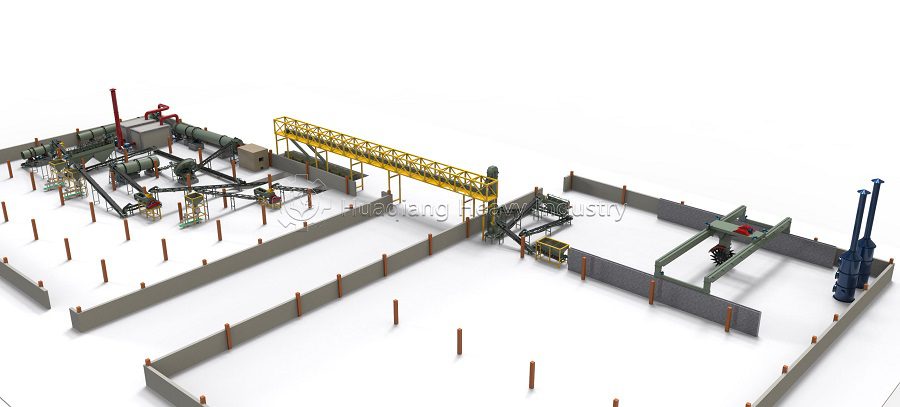

Production Line Configuration and Core Process Analysis: The entire production line follows a closed-loop design of “raw material resource utilization – fine processing – dual-product output – environmental compliance.” The equipment layout is scientific, the connections are tight, and the functions of each unit are complementary, ensuring a stable production capacity of 30,000 tons/year while achieving a dual improvement in product quality and environmental benefits.

Raw Material Pretreatment Unit: The Foundation of Waste-to-Treasure Process

Raw Material Feeding and Crushing: The production line starts at the loader-loaded hopper, adaptable to the rapid feeding needs of bulk agricultural waste such as livestock manure, straw, and mushroom residue. The feed inlet is equipped with spill prevention and impurity filtration devices to prevent large hard objects from entering. The raw materials are conveyed via a 6-meter belt conveyor to a 90-type vertical crusher. This equipment uses a high-speed impact crushing principle, with a high-chromium wear-resistant alloy cutter disc that can crush large raw materials (particle size ≤100mm) into uniform particles ≤3mm, achieving a crushing efficiency of 6 tons/hour, meeting the fineness requirements of subsequent processing. The crushing stage is equipped with a pulse dust collector and induced draft fan to effectively collect dust, with dust emission concentration ≤10mg/m³, meeting environmental standards.

Grading and Screening & Recycling: The crushed raw materials are transferred via a 9-meter belt conveyor to a 10×30-meter drum screen (presumably a 1.0×3.0 meter standard size). A single-layer screen design separates substandard coarse particles, which are then returned to the crusher for reprocessing via a 10-meter recycling belt conveyor, achieving a material utilization rate of 98%. Qualified fine materials are conveyed to the subsequent mixing stage via 5-meter and 7-meter belt conveyors, achieving a screening efficiency of 5.5 tons/hour, ensuring the purity and uniformity of the raw materials.

Dual-Production Line Core Processing Unit: Parallel Production of Granules and Powders

(I) Granular Organic Fertilizer Production Line

Precise Batching and Mixing: Raw materials are vertically conveyed to the automatic raw material batching silos (3 silos) via a 350-type bucket elevator (8 meters high). Each silo can store main materials, additives, and functional auxiliary materials separately, equipped with high-precision metering devices, ensuring a batching error of ≤1%. After batching, the materials are fed into a 50-type twin-shaft mixer via 7-meter and 26-meter belt conveyors. The mixer employs an anti-rotating blade design, ensuring a mixing uniformity error of ≤2%, laying the foundation for high-quality granulation.

Granulation, Drying, and Cooling: The mixed materials are transferred to the granulation stage via 4-meter forward/reverse belt conveyors and 12-meter belt conveyors (based on capacity estimates, this involves multiple flat-die granulators operating in parallel). The granulators utilize a hydraulic pressurization system, achieving a stable granulation rate of over 92% and particle size control of 3-5mm. After granulation, the wet granules are conveyed via a 10-meter belt conveyor to a 1.5×15-meter dryer, where a hot air furnace provides a stable heat source. The drying temperature is precisely controlled between 60-80℃, reducing the granule moisture content from 30% to below 12%. Subsequently, the granules are conveyed via an 8-meter belt conveyor to a 1.2×12-meter cooler, where a counter-current cooling process rapidly lowers the granule temperature to room temperature, increasing the granule strength to over 2.5MPa.

Coating and Finished Product Output: The cooled granules are conveyed via 11-meter and 18-meter belt conveyors to a 1.2×4.0-meter coating machine. Atomized spraying technology evenly coats the granules with a coating agent, improving their moisture resistance and slow-release nutrient effect. The coated granules undergo a second screening using a 1.8×6.0-meter drum screen. Qualified products enter the finished granule silo, and finally, quantitative packaging is completed using an automatic granule packaging scale, supporting 25kg and 50kg specifications with a packaging error ≤±0.2kg.

(II) Powdered Organic Fertilizer Production Line

Fine Grinding and Screening: After some raw materials are crushed and screened, they are fed into a 50-type twin-shaft mixer via 13.7m and 14m belt conveyors for formula mixing. They are then transferred to a 13-type pulverizer for secondary fine grinding, reducing the material to a fine powder of 100-150 mesh (0.1-0.15mm) to ensure the powder’s dissolution rate and absorption efficiency. The ground powder is then screened by a dedicated screening device, with qualified fine powder entering the finished powder silo.

Automated Packaging: The finished powder is quantitatively packaged using an automatic powder packaging scale. The equipment employs spiral feeding and weighing feedback control technology to prevent powder from flying. The packaging speed reaches 80 bags/hour, with high metering accuracy, ensuring standardized product output.

Environmental Protection and Auxiliary Units: Comprehensive Guarantee for Green Production

Waste Gas Treatment System: The production line is equipped with Y5-47-6c induced draft fans (for dryers), Y5-47-5 induced draft fans (for coolers), and dedicated dust removal fans. These are linked to pulse dust collectors, dust collection chambers, water washing towers, and scrubbers to provide multi-stage purification of dust and waste gas generated during production. Waste gas is washed in a water tank before being discharged through the chimney, ensuring that all emission indicators meet national environmental standards for the organic fertilizer industry.

Intelligent Control and Auxiliary Configuration: The production line integrates a PLC intelligent control system to monitor the operating parameters of each piece of equipment (temperature, speed, material level, etc.) in real time. It supports automatic fault alarms and data recording for refined management. Electric heating devices ensure production stability in low-temperature environments. All belt conveyors and bucket elevators adopt a sealed design to reduce material loss and dust pollution.

Core Advantages and Regional Adaptability of the Production Line

Dual Production Lines for Flexible Adaptation: Simultaneous production of granular and powdered organic fertilizers allows for flexible adjustment of capacity ratios based on market demand, achieving an annual capacity of 30,000 tons to meet the diverse fertilization needs of Southwest China.

Precise Matching to Regional Characteristics: Optimized crusher and mixer parameters to suit the characteristics of agricultural waste raw materials in Gao County, Sichuan Province, adapting to the processing requirements of high-humidity, high-fiber raw materials; the equipment features corrosion-resistant and moisture-proof designs, adapting to the rainy and humid climate of southern Sichuan.

Significant Environmental and Energy-Saving Benefits: Equipped with a complete dust removal and exhaust gas treatment system, achieving green production; the drying and cooling processes utilize energy-saving motors and heat recovery designs, reducing energy consumption by 15% compared to conventional production lines of the same capacity, helping customers reduce costs and increase efficiency.

Building a Complete System from Waste to Product

This successful 30,000-ton-per-year project demonstrates a holistic approach to organic fertilizer manufacturing. The entire organic fertilizer production line is a sophisticated system that bridges the gap between raw agricultural waste and high-value fertilizer products. While this configuration focuses on the post-fermentation processing stages, its success is built upon a foundation of high-quality raw compost.

The initial stage of efficient organic fertilizer fermentation is critical, typically achieved through advanced fermentation composting turning technology to produce mature, stable organic matter. Huaqiang Heavy Industry’s solution seamlessly integrates this pre-processed material into the automated granulation and powder production lines, creating a complete, value-adding system that supports both economic and environmental sustainability for local agriculture.

The successful commissioning of the 30,000-ton-per-year organic fertilizer production line in Gao County, Sichuan Province, not only demonstrates Zhengzhou Huaqiang Heavy Industry Technology Co., Ltd.’s professional strength in the R&D of complete sets of organic fertilizer equipment and multi-product line integrated design, but also provides an efficient solution for the resource utilization of agricultural waste in Southwest China. In the future, Huaqiang Heavy Industry will continue to focus on the needs of green agricultural development, optimize product performance and process solutions, provide more customers with customized and environmentally friendly organic fertilizer production equipment, and help the agricultural industry achieve high-quality and sustainable development.