The powder + granular organic fertilizer production line is an integrated solution designed specifically for the diversified production needs of organic fertilizer enterprises. Through its core design of “shared raw materials, differentiated processes, and universal equipment,” it simultaneously achieves large-scale production of both powdered and granular organic fertilizers. One set of equipment meets different application scenarios (powder is suitable for fertigation and drip irrigation; granules are suitable for strip application and broadcasting), significantly improving capacity utilization and market adaptability, and is suitable for green agriculture scenarios such as ecological planting and facility agriculture.

Production Line Configuration and Core Details

I. Raw Material Pretreatment and Sharing Unit: Laying the Foundation for Dual Products

(I) Raw Material Storage and Fermentation Pretreatment

Raw Material Warehouse and Fermentation System: Equipped with 3 large-capacity 100m³ raw material warehouses to store organic raw materials such as livestock and poultry manure, straw, and mushroom residue; equipped with a 500m³ windrow-type fermentation turner (or trough-type turner) to ferment and decompose the raw materials (decomposition degree ≥85%), removing odors and pathogens. The fermentation cycle is 7-15 days. After fermentation, the moisture content of the raw materials is controlled at 35%-45%, laying the foundation for subsequent processing.

Crushing and Impurity Removal: The fermented raw materials are conveyed to a 90-type vertical crusher via a 6-meter belt conveyor, crushed to ≤3mm (granular fertilizer raw materials) or ≤1mm (powdered fertilizer raw materials). During the crushing process, impurities such as stones and plastics are removed by an impurity removal device. The crusher is equipped with a pulse dust collector, achieving a dust collection efficiency of 99% and a material utilization rate of 98%.

(II) Precise Batching and Mixing

Multi-Group Batching System: Equipped with a 4-compartment batching machine, storing fermented organic fertilizer, straw charcoal, trace elements, and functional microbial agents respectively. A variable frequency screw batching scale is used to precisely control the proportions (functional microbial agent addition amount 0.1%-0.5%), with a batching error ≤±1%. When producing powdered fertilizer, soluble additives such as humic acid and amino acids are added to improve the fertilizer’s water solubility; when producing granular fertilizer, 3%-5% binder (such as bentonite or starch) is added to ensure granulation effect.

Twin-shaft mixer: A 60-type twin-shaft mixer is used to thoroughly mix the multi-component raw materials, with a mixing uniformity error ≤2%. The mixer is equipped with a spray humidification/drying device to adjust the raw material moisture content according to the product type (powdered fertilizer: 20%-25%; granular fertilizer: 30%-35%).

II. Process branching unit: Parallel production of powdered and granular fertilizers

(I) Powdered organic fertilizer production line (branching branch 1)

Fine grinding and sieving: The mixed raw materials are further ground to 100-150 mesh using a 13-type ultrafine pulverizer to ensure uniform powder fineness and rapid dissolution. After grinding, the powder is graded using a 1.2×4.0 meter vibrating screen to remove substandard coarse particles, which are then returned to the pulverizer for reprocessing.

Finished Product Storage and Packaging: Qualified powder is conveyed via a sealed screw conveyor into two 50m³ finished product silos (dedicated to powder form). The silos are equipped with dehumidification and ventilation devices to prevent moisture absorption and clumping. The packaging process utilizes a dual-station automatic powder packaging scale with a screw feeder and dust cover design to prevent dust from flying. It supports switching between 20kg and 25kg specifications, with a measurement error ≤ ±0.2kg and a packaging speed of 80 bags/hour.

(II) Granular Organic Fertilizer Production Line (Branch 2) Core Granulation Process: The mixed raw materials are conveyed via an 8-meter belt conveyor to a Φ3.2×1.2-meter disc granulator (or rotary drum granulator). Through centrifugal force and the action of a binder, 3-5mm rounded granules are formed, with a granulation rate ≥90%. The granulator is equipped with a spray humidification device to adjust moisture in real time and ensure granule strength.

Drying and Cooling/Curing: Wet granules are conveyed via a 10-meter belt conveyor into a Φ1.8×15-meter drum dryer, where hot air circulation heating is used to control the drying temperature at 60-80℃ (to prevent inactivation of functional bacteria), reducing the moisture content to below 12%. They then enter a Φ1.5×12-meter counter-current cooler for rapid cooling to room temperature, increasing the granule strength to over 2.0MPa, making them more resistant to storage and transportation and less prone to pulverization.

Grading, Screening, and Packaging: The cooled granules are graded using a Φ1.5×6.0-meter drum screen (3-5mm sieve openings). Unqualified granules are returned to the granulator for reprocessing. Qualified granules are fed into two 80m³ finished product silos (dedicated to granules) and packaged using a dual-station automatic granule packaging scale, supporting 25kg and 50kg sizes at a packaging speed of 100 bags/hour.

III. Environmental Protection and Intelligent Control Unit: Green and Stable Production

(I) Environmental Protection System

Dust Treatment: Four MC-96 pulse dust collectors are installed in the crushing, screening, and packaging stages, with a total air volume of 18,000 m³/h. The dust concentration in the workshop is ≤10 mg/m³, meeting environmental standards.

Exhaust Gas Treatment: Odors generated during fermentation are purified by a biological filter before being discharged, with an ammonia concentration ≤15 mg/m³.

Wastewater Treatment: Production cleaning wastewater is treated by sedimentation and filtration tanks and then recycled for raw material fermentation humidification, achieving zero wastewater discharge.

(II) Intelligent Control System

An integrated PLC central control system is installed, with preset production modes for powder and granules. Process parameters (crushing fineness, ingredient ratio, drying temperature, etc.) can be switched with one click. Real-time monitoring of equipment operation status, raw material moisture content, and finished product output is provided. Automatic fault alarms and data recording (storage period ≥90 days) are supported, reducing manual intervention.

Core Advantages and Adaptability of the Production Line

Flexible Dual-Product Switching: One set of equipment enables simultaneous/switching production of powdered and granular organic fertilizers, with a conversion time of ≤2 hours. This adapts to different customer needs (growers, agricultural input dealers) and application scenarios, enhancing market competitiveness.

Highly Efficient and Stable Production Capacity: Hourly production capacity reaches 5-8 tons (powder) or 6-10 tons (granules), with an annual capacity of 40,000-80,000 tons, suitable for the production needs of small, medium, and large-scale organic fertilizer enterprises. Equipment sharing rate exceeds 70%, saving 30% in investment costs and 25% in floor space compared to two separate production lines.

Superior Product Quality: Powdered fertilizer has uniform fineness and good water solubility, suitable for fertigation and drip irrigation; granular fertilizer is round, dense, and high-strength, suitable for mechanized strip application and broadcasting, with a functional bacteria survival rate of over 90%, ensuring fertilizer efficacy.

Green and Environmentally Friendly: The entire process features a sealed design, dust recovery, and wastewater recycling, meeting national environmental protection requirements. The fermentation process also enables the resource utilization of agricultural waste, contributing to the development of green agriculture.

Suitable and Unsuitable Scenarios

Suitable Scenarios: Large-scale organic fertilizer production enterprises and agricultural waste resource utilization projects that require the supply of both powdered and granular organic fertilizers, suitable for diversified fertilization needs such as ecological planting, fruit and vegetable greenhouses, and grain crops.

Unsuitable Scenarios: Raw materials with a moisture content >50% and that are not fully fermented (easily leading to equipment blockage and product spoilage); pure functional microbial fertilizers (requiring low-temperature processing and additional low-temperature drying equipment).

A Flexible Solution for Diverse Market Needs

This integrated powder + granular organic fertilizer production line provides manufacturers with a highly adaptable and efficient foundation. It enables the flexible production of two major fertilizer forms from a shared raw material base, maximizing equipment utilization and market responsiveness.

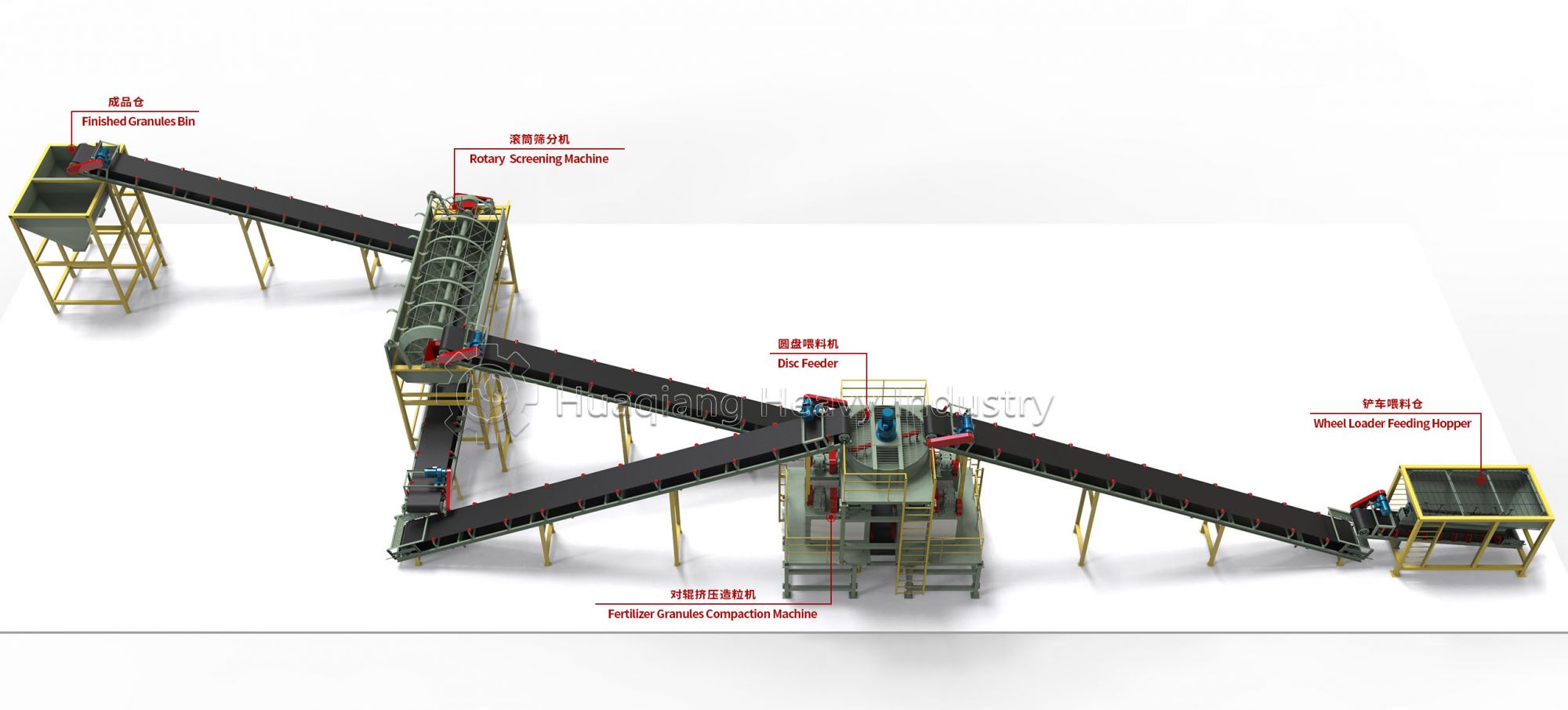

While specialized for organic production, this line represents a category of advanced fertilizer production machine technology. Its drum granulation process using a rotary drum granulator is a common and effective fertilizer processing machine method. For operations looking to expand into mineral-based products, the principles of this line are complementary to an npk production line. The granulation stage could be adapted using alternative technologies, such as a roller press granulator production line for dry fertilizer granules compaction, or a disc granulation production line. These technologies are all part of modern npk fertilizer production technology, allowing manufacturers to build upon this organic foundation to create a comprehensive portfolio that serves both organic and conventional agricultural markets.

We warmly welcome people from all walks of life to visit, guide, and discuss business with us, and work hand in hand with Huaqiang Heavy Industry to promote the high-quality development of green agriculture!