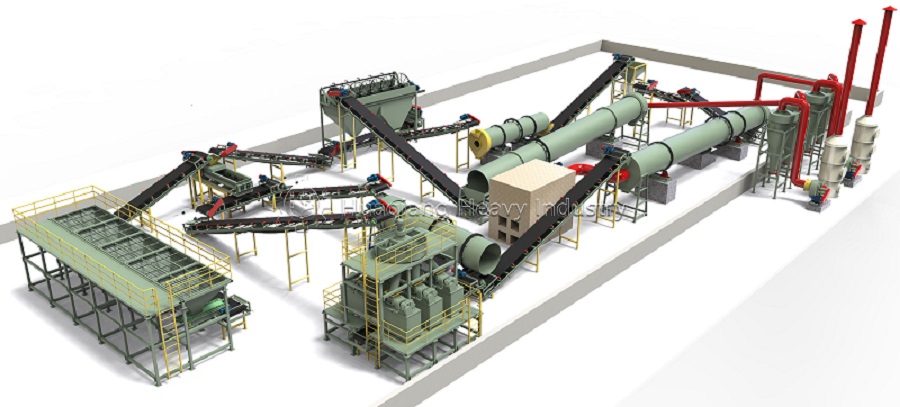

In November 2025, Zhengzhou Huaqiang Heavy Industry Technology Co., Ltd. successfully completed the installation and commissioning of a roller extrusion + drum granulation composite production line tailored for a Turkish client, officially entering the stage of large-scale production. This production line innovatively integrates the dual core technologies of roller extrusion granulation and drum granulation, consolidating the entire chain from raw material pretreatment, precise batching, composite granulation, drying and cooling, coating and screening, to finished product packaging. With a robust configuration of 6 roller granulators + drum granulators, a highly automated process design, and quality standards adapted to the Eurasian market, it has become a benchmark project for Chinese high-end fertilizer equipment in overseas markets, providing Turkish fertilizer producers with a customized solution that combines flexibility and scalability.

Production Line Configuration and Core Process Analysis

The entire production line follows a closed-loop logic of “refined raw material pretreatment – precise batching and mixing – composite granulation – post-processing and finishing – standardized finished product output.” The equipment layout is scientifically compact, with seamless connections between units. The synergistic application of dual granulation processes provides dual guarantees for product quality and production capacity, fully meeting the diverse fertilizer production needs of Turkey.

Raw Material Pretreatment and Precision Batching Unit: Laying a Solid Foundation for Production

Multi-dimensional Crushing Processing: The production line is equipped with four raw material bins, which can store nitrogen, phosphorus, and potassium main raw materials and mineral auxiliary materials respectively. The raw materials are transferred via a 7-meter belt conveyor to the dual crushing system—a cage crusher and a new type of roller crusher working in tandem. Cage crushers are used for coarse crushing of large raw materials, reducing particles ≤100mm in diameter to ≤20mm. The new roller crusher performs fine crushing, employing a high-strength, wear-resistant roller shaft design. Through the squeezing and shearing action between the rollers, the coarsely crushed raw materials are further pulverized to uniform particles ≤3mm, achieving a crushing efficiency of 8 tons/hour, meeting the stringent fineness requirements of various granulation processes. The crushing stage is equipped with a cyclone dust collector and induced draft fan, achieving a dust collection efficiency of 99% and a dust emission concentration ≤10mg/m³, complying with EU environmental standards.

Precise batching and uniform mixing: The crushed raw materials are conveyed to a 5-bin batching machine via 9-meter and 7-meter belt conveyors. Each bin is equipped with a high-precision metering screw conveyor. Combined with a PLC intelligent control system, the feed rate of each raw material can be automatically adjusted according to the preset formula, with a batching error ≤0.8%, ensuring accurate fertilizer nutrient ratios. The batched materials are fed into a 40-type twin-shaft mixer via a 12-meter belt conveyor. The equipment employs an anti-rotating blade design with a wear-resistant coating on the blade surface. During mixing, the materials undergo strong convection, shearing, and tumbling motions, resulting in a mixing uniformity error of ≤2%, providing a homogeneous raw material foundation for the subsequent dual granulation process.

Core Composite Granulation Unit: Dual Processes Create High-Quality Granules

Roller Extrusion Granulation Pretreatment: The mixed materials are precisely fed to six 2.0-type roller extrusion granulators via a 3-meter disc feeder. The feeder utilizes variable frequency speed regulation and automatic material level control technology to ensure uniform feeding to all six granulators. This type of granulator adopts a high-strength roller design, with roller skins made of high-chromium alloy. After quenching treatment, the hardness reaches HRC62 or higher, exhibiting extremely high wear resistance. The extrusion pressure can be precisely controlled within the range of 8-18MPa, compressing materials into uniformly dense flaky granules with a stable granulation rate exceeding 93%, providing a high-quality “masterbatch” foundation for subsequent drum granulation. Six granulators operate in parallel, each with a capacity of 2.5 tons per hour, achieving a pre-processing capacity of 15 tons per hour through combined operation, significantly improving overall production efficiency.

Drum granulation molding optimization: The flaky granules extruded by the rollers are transferred to the Φ1.6X6 meter drum granulator via 5-meter, 7-meter, and 10-meter belt conveyors. This equipment is the core of the composite granulation process. The inner wall of the drum is lined with special wear-resistant plates, and the spiral layout of the lifting plates drives the material to continuously tumble within the drum. Simultaneously, the melting tank heats and melts coating agents, binders, and other auxiliary materials, which are then evenly sprayed onto the material surface through an atomizing spraying system. This further rolls the flaky granules into round, uniform spherical particles, with a particle size that can be precisely controlled within 3-5mm. The drum granulator uses a variable frequency speed control design, allowing for flexible adjustment of the rotation speed (10-20 r/min) according to the granulation effect. The spherical granulation rate reaches over 95%, and the granule compressive strength reaches 2.8MPa. It is not prone to pulverization and fully meets the needs of long-distance transportation and field application in Eurasia.

Post-processing and Finished Product Output Unit: Quality Upgrade and Efficient Delivery

Drying, Cooling, and Shaping: Wet granules from drum granulation are conveyed via a 15-meter belt conveyor to a Φ1.5X15-meter dryer. A hot air furnace provides a stable heat source, and the drying temperature is precisely controlled between 70-90℃. A hot air circulation process reduces the granule moisture content from 30% to below 12%, with a drying uniformity error of ≤3%. Subsequently, the granules are conveyed via 7-meter and 5-meter belt conveyors to a Φ1.5X15-meter cooler. A counter-current cooling process rapidly lowers the granule temperature to room temperature (±5℃), further improving granule hardness and storage stability. The cooling efficiency reaches 18 tons/hour.

Coating and Screening Optimization: Cooled granules are conveyed via a 13-meter belt conveyor to a Φ1.2X5-meter coating machine. A special coating agent is evenly applied to the granule surface using atomized spraying technology, forming a dense protective film that effectively improves the fertilizer’s resistance to moisture absorption, anti-caking properties, and slow-release nutrient effect. The coated granules are transferred to a Φ1.8X6 meter screening machine via a 10-meter belt conveyor. A double-layer screen design separates the qualified granules. Unqualified granules are crushed by a 60-type vertical crusher and then returned to the raw material mixing front end via 9-meter and 7-meter return conveyors, re-entering the granulation process. Material utilization reaches 99%.

Finished Product Storage and Automated Packaging: Qualified granules are temporarily stored in a finished product silo equipped with a material level monitoring system and dehumidification and ventilation devices to ensure stable product storage. The packaging process utilizes an automatic packaging machine that supports rapid switching between various sizes such as 25kg and 50kg. It employs gravity metering principles with high-precision sensors, achieving a metering error of ≤±0.1kg and a packaging speed of 150 bags/hour. Combined with a gantry crane and transfer system, it enables rapid warehousing and shipping of finished products.

Environmental Protection and Intelligent Control Unit: Precise Control of Green Production

Comprehensive Environmental Protection System: The production line is equipped with a complete waste gas treatment system. Waste gas from the hot air furnace undergoes multi-stage purification treatment via cyclone dust collectors and spray towers before being discharged in compliance with standards. Dust generated in each production stage is centrally collected by induced draft fans and sent to the dust removal system, achieving zero dust leakage. The water tank and spray tower are designed in conjunction to effectively treat harmful components in the waste gas, and all emission indicators comply with EU environmental regulations.

Intelligent Centralized Control: The production line integrates a central control room and a complete set of electrical control cabinets, adopting a PLC intelligent control system that can monitor the operating parameters of each piece of equipment in real time (speed, pressure, temperature, material level, etc.), supporting automatic fault alarms, data recording, and remote diagnostic functions. The walking platform facilitates operators’ maintenance and repair of high-level equipment, achieving precise control and safe and efficient operation of the entire production process.

Core Advantages and Regional Adaptability of the Production Line

Innovative Composite Granulation Process: The combination of roller extrusion and drum granulation ensures both particle density and strength, while also achieving rounded particle shape. Product quality far surpasses that of single-granulation processes, meeting the demands of the high-end fertilizer market.

Precise Adaptation to Regional Conditions: Core equipment utilizes high-temperature, wear-resistant, and corrosion-resistant materials, adapting to the high-temperature and dry characteristics of Turkey’s Mediterranean climate. The production line design complies with EU technical standards and environmental requirements, facilitating customer expansion into the Eurasian market.

High Efficiency, Energy Saving, and Cost-Effectiveness: The coordinated configuration of six roller granulators and drum granulators achieves a stable production capacity of 20 tons/hour, with an annual capacity of up to 150,000 tons. The entire process employs energy-saving motors and optimized process design, reducing energy consumption by 15% compared to conventional production lines with the same capacity, significantly lowering customer production costs.

The successful commissioning of the roller extrusion + drum granulation production line in Turkey not only demonstrates Zhengzhou Huaqiang Heavy Industry Technology Co., Ltd.’s comprehensive strength in the R&D of composite granulation equipment and the implementation of high-end overseas projects, but also provides efficient and stable equipment support for the modernization of agriculture in the Eurasian region. In the future, Huaqiang Heavy Industry will continue to focus on the diversified needs of global customers, optimize product performance and service solutions, and provide customized high-end fertilizer production solutions for more countries and regions, allowing “Made in China” to shine even brighter in the international market.

Synergizing Technologies for Superior Product Quality

The successful delivery of this composite granulation line to Turkey exemplifies Huaqiang Heavy Industry’s expertise in integrating multiple advanced technologies into a single, high-output fertilizer production machine system. This project highlights a sophisticated approach to the modern npk fertilizer manufacturing process, where product quality is paramount.

The line’s innovation lies in the strategic combination of two proven granulation methods. The initial stage utilizes a roller press granulator production line configuration, where multiple fertilizer compaction machine units perform dry fertilizer granules compaction to create a dense pre-form. This is seamlessly followed by a finishing stage of drum granulation in a rotary drum granulator, which rounds and polishes the particles. This hybrid process leverages the strengths of both the fertilizer compactor for density and the drum for shape, creating a superior final product that meets the stringent demands of the high-end Eurasian market within an efficient npk manufacturing process.

This project underscores a key trend in professional fertilizer manufacturing: the intelligent integration of complementary technologies to achieve product characteristics that single-process lines cannot match, providing clients with a distinct competitive advantage.