Precise Proportioning, Quality Assurance

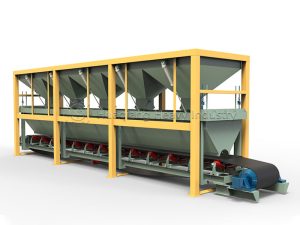

The single silo single weigh batching system uses independent weighing units, with each material silo equipped with high-precision electronic scales to ensure accurate weighing of each raw material according to preset formulas. This design eliminates potential cross-contamination and measurement errors in traditional batching systems, providing reliable quality assurance for products.

Automated Production, Efficiency Improvement

The system achieves fully automated operation through PLC or microcomputer control systems, from material conveying and precise weighing to mixing, without manual intervention. This not only significantly improves production efficiency but also reduces labor costs, enabling 24-hour continuous production.

Versatile Applications, Wide Adaptability

This system can be used with BB fertilizer equipment, organic fertilizer equipment, and NPK compound fertilizer equipment, suitable for various industries including chemical, pharmaceutical, food, and building materials. Whether handling powders, granules, or liquid raw materials, the system can process them flexibly to meet different formulation requirements.

Core Workflow

After system startup, materials are transported from their respective storage silos to weighing units through conveying devices, where electronic scales precisely measure the weight of each material. When all materials reach the specified weight, the system controls the conveying device to send materials into the mixer. After mixing is completed, automatic unloading proceeds to the next process.

Safety and Environmental Protection

Equipped with comprehensive safety protection systems, including overload protection and emergency stop devices, ensuring the safety of equipment and operators. Meanwhile, enclosed material silos and conveying systems effectively reduce dust pollution, achieving environmentally friendly production.

Easy Operation and Maintenance

With user-friendly human-machine interface design and simple parameter settings, operators can quickly master system operation. Modular design makes equipment maintenance more convenient, significantly reducing downtime.

Investment Value

Although the initial investment in a single silo single weigh dynamic batching system is relatively high, the resulting quality stability, production efficiency, and cost savings provide significant return on investment. For enterprises pursuing high-quality products and large-scale production, this system is a wise choice for achieving modernized production.

Integrated Production Solutions for Modern Fertilizer Manufacturing

The single silo single weigh batching system serves as the crucial foundation for various fertilizer production operations, seamlessly integrating with complete npk fertilizer production line setups and organic fertilizer production line configurations. This precision batching technology pairs exceptionally well with granulation equipment like the disc granulator machine in a comprehensive disc granulation production line, ensuring formula accuracy before materials enter critical fertilizer granulation processes.

For specialized production needs, this versatile batching system adapts to both conventional npk fertilizer line operations and sophisticated bio organic fertilizer production line requirements. The precisely batched materials can be directed to various fertilizer granulator options, including the efficient double roller press granulator for compaction granulation or traditional disc granulator systems for rotary agglomeration. When combined with complementary equipment like the windrow composting machine for initial processing, manufacturers achieve a complete, automated production circuit from raw material to finished product, maximizing both quality and operational efficiency.