With the rapid development of ecological agriculture, the market demand for organic fertilizers continues to rise, and the corresponding production methods are also becoming increasingly diversified. Based on differences in fermentation methods and production scale, the current mainstream organic fertilizer production methods mainly include the windrow composting method, the fermentation tank method, and the Bokashi method. Each method has its own focus in terms of process design, equipment requirements, and applicable scenarios, respectively adapting to large-scale commercial production, precise customized production, and small-scale home/garden planting needs, collectively promoting the resource utilization of agricultural waste.

The windrow composting method is the mainstream choice for large-scale aerobic composting and is widely used in large organic fertilizer production enterprises, especially suitable for processing large quantities of agricultural waste such as crop straw and livestock manure from large-scale farms. The core advantage of this method lies in its strong large-scale processing capacity. Through dedicated windrow turning equipment (such as crawler-type windrow turners and trough-type windrow turners), automated turning of tens of thousands of tons of compost piles can be achieved, significantly improving labor efficiency and precisely controlling the aeration and temperature distribution of the compost pile. In the production process, the compost pile is usually stacked in windrows, with a height of 1.5-2 meters and a width of 3-5 meters. The windrow turner regularly turns the pile to maintain a stable temperature of 50-60℃, ensuring the killing of pathogens and the complete decomposition of organic matter. In addition, the equipment investment of the windrow composting method is relatively controllable, and the production process is mature, making it suitable for producing general-purpose organic fertilizers. The products are mainly supplied to large-scale planting bases and grain-producing areas, effectively reducing the reliance of large-scale agricultural production on chemical fertilizers and solving the problem of disposing of large quantities of agricultural waste. However, this method is subject to significant site limitations, requiring sufficient composting space, and the fermentation cycle is relatively long, usually requiring 25-35 days.

The fermentation tank method uses closed tank equipment as its core and is suitable for aerobic or anaerobic fermentation production requiring a highly controlled fermentation environment, especially widely used in the production of liquid organic fertilizers, such as amino acid liquid fertilizers and humic acid liquid fertilizers. The greatest advantage of this method lies in the precise and controllable fermentation process. The sealed tank effectively isolates the process from external environmental interference. Through an intelligent control system, parameters such as temperature, oxygen content, and pH value are adjusted in real time, ensuring that microorganisms remain in their optimal metabolic state. This results in a fermentation efficiency increase of over 30% compared to traditional methods. In anaerobic fermentation mode, the fermentation tank can efficiently process high-concentration organic wastewater and livestock manure, producing organic fertilizer while simultaneously recovering biogas, achieving a dual output of energy and fertilizer. The aerobic fermentation mode can be used to produce high-quality powdered organic fertilizer. By precisely controlling the carbon-nitrogen ratio and fermentation time, the organic matter content and nutritional stability of the product are improved. The fermentation tank method is suitable for small and medium-sized fine fertilizer production enterprises. The products are mostly customized formulations, supplied to facilities such as greenhouse agriculture and fruit and vegetable planting bases that have high requirements for fertilizer quality. However, the initial investment in equipment is high, and the technical requirements for operators are also more stringent.

The Bokashi method is a small-scale anaerobic fermentation composting method. With its advantages of simple operation and short fermentation cycle, it has become an ideal choice for home gardening, backyard vegetable gardens, and small farmers. This method uses specific functional microorganisms (such as EM bacteria) as the core. Kitchen waste, household plant residues, and a small amount of animal manure are mixed with molasses and EM bacterial agents and placed in a sealed container for anaerobic fermentation. Composting is completed in only 7-15 days, shortening the composting cycle by more than half compared to traditional methods. The fermentation products of the Bokashi method are divided into solid fertilizer and fermentation liquid. The solid fertilizer can be directly applied to the soil or used as a seedling substrate, and the fermentation liquid can be diluted and sprayed as a foliar fertilizer, achieving full resource utilization. In addition, this method does not require large equipment, has a low operating threshold, and can effectively treat household organic waste, reducing the amount of household waste, thus possessing both economic value and environmental significance. However, the Bokashi method has a small processing scale and is not suitable for large-scale commercial production. Furthermore, strict control of sealing conditions is required during the fermentation process; improper sealing can easily lead to fermentation failure and produce unpleasant odors. The differentiated development of different production methods allows organic fertilizer production to adapt to different needs, providing diversified technical support for green agricultural development.

From Fermentation to Finished Product: The Industrial Pathway

The diverse composting methods—windrow, tank, and Bokashi—each serve as the starting point for transforming organic waste into valuable amendments. To scale these processes for commercial markets, the compost produced must be integrated into a formal organic fertilizer manufacturing system, which standardizes and enhances the final product.

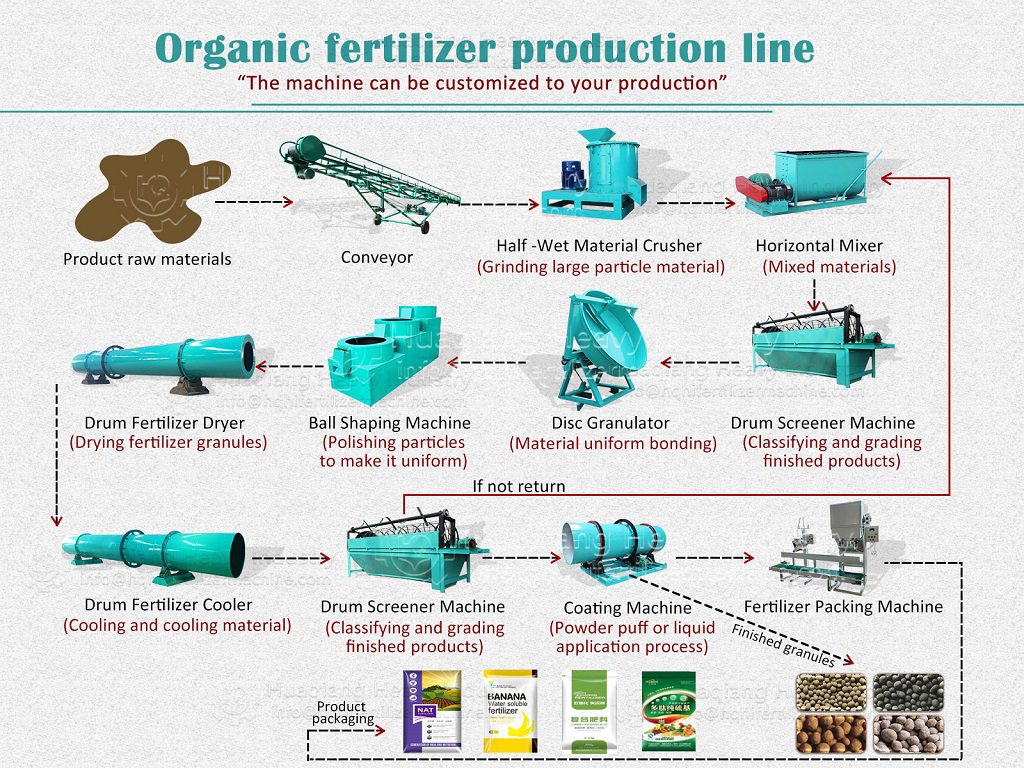

For large-scale operations utilizing windrow composting, the mature compost is processed through a complete organic fertilizer production line. The initial stage relies on advanced fermentation composting turning technology, often using equipment like a chain compost turning machine. To create a market-ready product, this compost undergoes organic fertilizer production granulation. Producers can choose specialized systems like an organic fertilizer disc granulation production line for uniform pellets or a more flexible organic fertilizer combined granulation production line. If microbial inoculants are added, this entire system becomes a sophisticated bio organic fertilizer production line, ensuring the survival and efficacy of beneficial microbes in the final product. This integration bridges the gap between raw composting and commercial-grade fertilizer.Ultimately, the choice of initial composting method defines the feedstock, while the subsequent industrial processing line defines the quality, consistency, and scalability of the fertilizer that reaches the farmer, enabling sustainable practices at every scale.