When a fertilizer plant decides to upgrade its production line machinery to increase output, it seems like a quick path to greater efficiency. However, in practice, a series of interconnected issues often arise, spanning technical, operational, cost, and safety aspects.

When a fertilizer plant decides to upgrade its production line machinery to increase output, it seems like a quick path to greater efficiency. However, in practice, a series of interconnected issues often arise, spanning technical, operational, cost, and safety aspects. The core challenge frequently lies in fertilizer granules compaction consistency, where even minor adjustments to the fertilizer production machine can create ripple effects throughout the entire NPK manufacturing process.

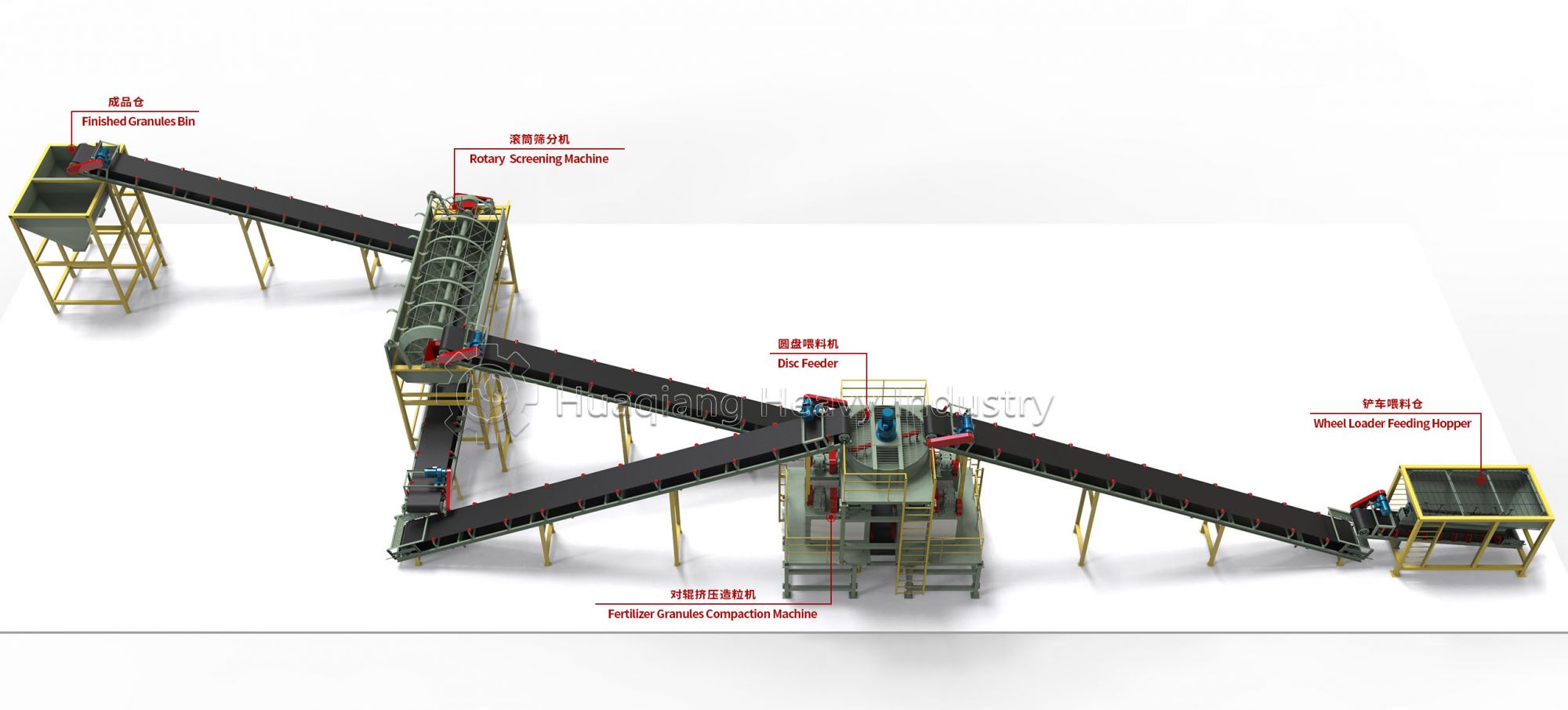

For instance, switching from a rotary drum granulator to a roller press granulator might improve production speed but create downstream complications in the organic fertilizer production line. The fertilizer compaction machine may require different raw material formulations, while the organic fertilizer production machine might struggle with altered moisture content from the new compaction method. These technical interdependencies often reveal themselves only during operation, requiring additional calibration, staff retraining, and sometimes even partial line reconfiguration – turning what seemed like a straightforward upgrade into a complex optimization challenge affecting everything from product quality to worker safety.

First, technology mismatch and integration issues are common. Upgraded, high-capacity machinery (such as a new granulator or mixer for a nitrogen, phosphorus, and potassium compound fertilizer production line) may not be compatible with the existing production line’s cadence. For example, a fertilizer plant in Shandong Province replaced an aging compost turner in its organic fertilizer production line with a high-speed model to increase output. However, it discovered that the subsequent drying equipment (still using the original, low-capacity configuration) was unable to handle the sudden increase in semi-finished products. This created a “bottleneck effect,” forcing the upgraded machinery to operate at half capacity, failing to achieve the expected increase in output and even resulting in material backlogs and waste. Furthermore, if the advanced control systems used in the new equipment (such as IoT-based smart monitoring) are incompatible with the plant’s existing centralized control platform, data disconnection may occur, making it impossible to coordinate production parameters (such as temperature and mixing ratio) across the entire production line. Second, runaway cost overruns and extended payback periods often catch factories off guard. Beyond the initial equipment purchase costs, hidden costs accumulate. A Henan factory upgraded its bulk mixed fertilizer production line to expand granular fertilizer production, initially budgeting $800,000 for a new batcher and conveyor belt. However, during installation, the factory discovered the existing floor could no longer support the weight of the new equipment, necessitating an additional $200,000 in structural reinforcement. Following the upgrade, the factory also had to spend $50,000 on employee training to operate the new automatic feeding system and $30,000 on spare parts because the new equipment’s components were not interchangeable with the old. These unplanned costs extended the payback period from the projected 18 months to over 24 months, putting pressure on the factory’s cash flow.

Third, operational disruptions and quality fluctuations pose immediate risks. Equipment upgrades often require production downtime—even a short one- to two-week stoppage can delay orders, especially for factories with long-term bio-organic fertilizer production contracts, which have tight raw material fermentation cycles. Even worse, upon resumption of production, untrained operators may mishandle the new equipment. When upgrading the pulverizing equipment in its organic fertilizer production line, a factory in Jiangsu discovered that operators unfamiliar with the new equipment’s adjustable speed settings were using excessive pulverizing force. As a result, 15% of the finished organic fertilizer pellets were too fine (not meeting particle size standards) in the first month after the upgrade. This not only resulted in a 5% loss of production due to rework, but also damaged the factory’s reputation with key customers.

Fourth, safety and compliance risks should not be ignored. Upgraded machinery (for example, the high-pressure reactor in the NPK fertilizer production line) may have new safety requirements that the factory’s existing procedures fail to address. For example, a fertilizer plant in Hebei installed a new, high-capacity blender for NPK fertilizer production but failed to update its safety inspections. During a routine run, the blender’s overheat protection system (a new feature) malfunctioned. Unaware of how to troubleshoot the problem, the worker continued to operate the blender, ultimately resulting in a minor material burn. Furthermore, if the upgraded machinery fails to meet the latest environmental standards (for example, improving dust removal efficiency in bulk mixed fertilizer production lines), the factory could face fines or production suspensions from environmental protection authorities, further delaying the achievement of production targets. In summary, while machinery upgrades are intended to increase production, they require comprehensive planning—from assessing technology compatibility and budgeting for full costs to employee training and updating safety procedures. Neglecting any one of these areas can turn a well-thought-out upgrade into a source of operational chaos.