.jpg)

Introduction

In the fertilizer production process, granulation is a crucial step. Choosing the appropriate granulation equipment not only affects product quality but also directly impacts production efficiency and operational costs. The mainstream granulation equipment in the current market includes rotary drum granulators and fertilizer compaction machines (roller press granulators). This article provides an in-depth analysis of these two technologies from multiple dimensions to offer reference for production enterprises in equipment selection.

Working Principle Comparison

The rotary drum granulator uses a rotating cylinder to make materials continuously roll and agglomerate under gravity, while spraying liquid binders to promote particle formation. This granulation method belongs to wet granulation, producing relatively regular-shaped particles with smooth surfaces.

The compaction granulator uses two counter-rotating press rollers to forcibly compress dry powder materials into shape, belonging to dry granulation. Materials form dense flakes or granules under high pressure.

Technical Characteristics Comparison

The comparison between rotary drum granulators and compaction granulators reveals distinct characteristics across several key parameters. Rotary drum granulators operate on wet agglomeration principles, producing spherical particles with smooth surfaces and medium strength, but require higher energy consumption due to the necessary drying process. They are suitable for most fertilizer raw materials and excel in large-scale continuous production. In contrast, compaction granulators utilize dry compression technology, generating irregularly shaped particles with relatively rough surfaces but higher strength. They demonstrate lower energy consumption, are particularly well-suited for heat-sensitive materials, and are ideal for medium-scale production operations.

.jpg)

.jpg)

Application Scenario Analysis

Advantageous Scenarios for Rotary Drum Granulator

Rotary drum granulators are particularly suitable for large-scale continuous production, especially for compound fertilizers and organic-inorganic compound fertilizers. The spherical particles produced have an attractive appearance and high market acceptance. For compound fertilizers requiring multiple trace elements and additives, rotary drum granulators can achieve good uniform mixing.

Advantageous Scenarios for Compaction Granulator

Compaction granulators have obvious advantages in processing heat-sensitive materials, such as certain bio-fertilizers and special chemical fertilizers. Since no drying process is required, they can effectively preserve active ingredients in the materials. Additionally, their equipment investment is relatively low, suitable for small and medium-scale production enterprises.

Selection Recommendations

Choose rotary drum granulator when: Large-scale continuous production is needed, spherical product appearance is required, wide raw material adaptability is needed, and complete drying system support is available.

Choose compaction granulator when: Processing heat-sensitive materials, investment budget is limited, production scale is medium, particle shape requirements are not strict, and energy consumption reduction is desired.

Conclusion

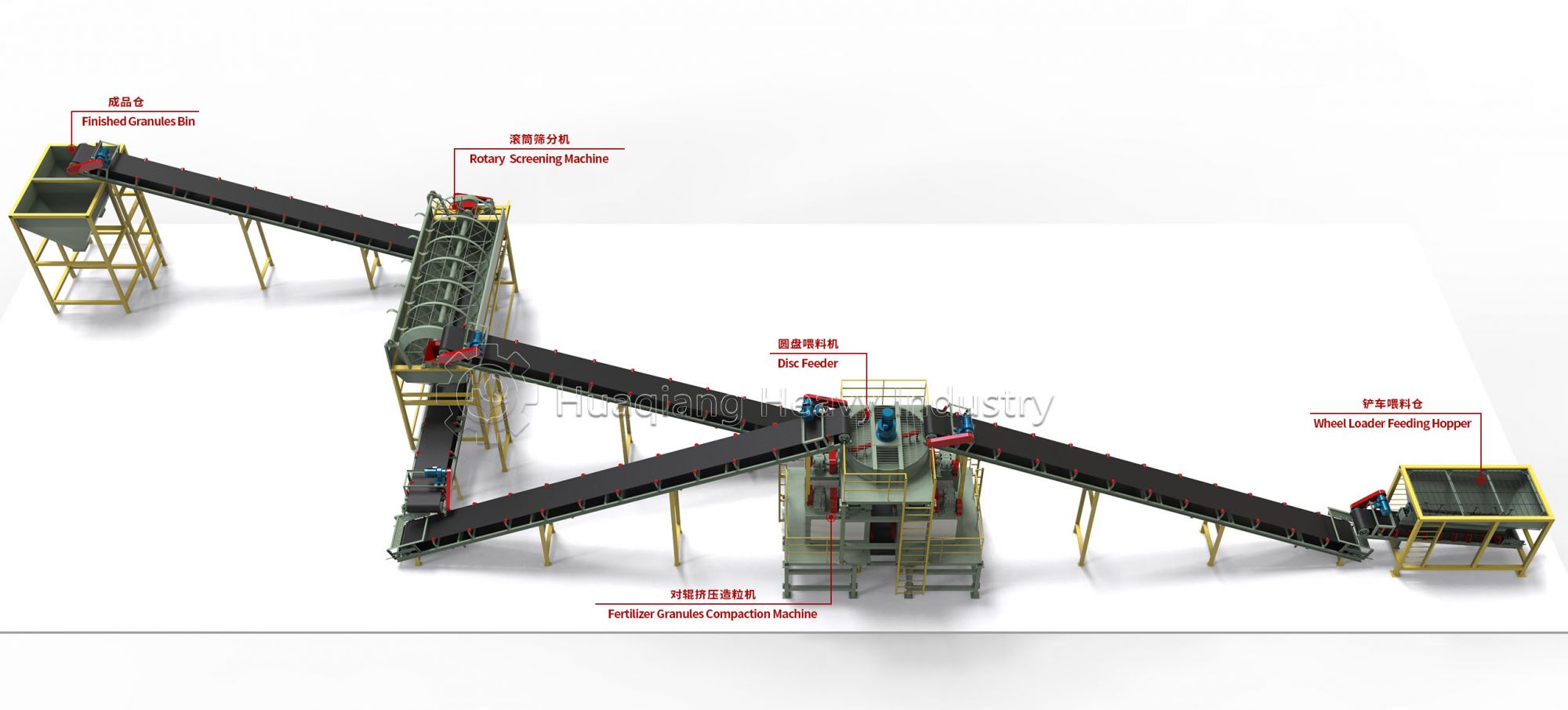

In the NPK manufacturing process, selecting appropriate granulation technology is crucial for quality and efficiency. The rotary drum granulator demonstrates significant advantages in large-scale NPK fertilizer production lines, producing uniformly spherical granules with excellent appearance and structural integrity. Meanwhile, the roller press granulator production line utilizes fertilizer granules compaction technology, making it particularly suitable for materials requiring high-density formulation. For organic fertilizer fermentation process, specialized fertilizer compaction machines often prove more effective in handling the unique characteristics of composted materials.

The drum granulator remains the preferred choice for conventional NPK fertilizer manufacturing process setups where production volume and product appearance are prioritized. However, when processing materials from the organic fertilizer fermentation process or dealing with specialized formulations, the fertilizer production machine based on extrusion technology offers superior energy efficiency. Advanced fermentation composting technology for organic fertilizer often pairs well with compaction-based systems, creating synergistic effects in complete fertilizer production lines.

Ultimately, successful NPK production line implementation requires careful technology matching. Manufacturers should consider integrating both granulation methods within their fertilizer production machine setups, leveraging the drum granulator’s capacity with the roller press’s efficiency. This hybrid approach to fertilizer granules compaction and granulation maximizes flexibility across different production requirements, from standard NPK manufacturing process to specialized organic fertilizer fermentation process applications, ensuring optimal resource utilization and product quality.