Introduction: Coating Technology Innovation for Enhanced Fertilizer Efficiency

In the context of global agriculture’s pursuit of sustainability and high efficiency, improving fertilizer use efficiency, reducing nutrient loss, and simultaneously enhancing soil health have become core objectives of fertilizer technology innovation. Traditional single-nutrient chemical fertilizers often face challenges like leaching and volatilization, while organic fertilizers, though beneficial for soil fertility, may lack immediacy. Organo-mineral fertilizers (OMFs), a novel type integrating organic matter with mineral nutrients, hold promise for combining the strengths of both. This article focuses on a new method for efficiently producing high-performance OMFs using a disc (pan) granulator through innovative coating technology. It explores the complete technical pathway from formulation design and equipment calculation to structural characterization, providing scientific insights for developing next-generation intelligent and environmentally friendly fertilizers.

I. Core Innovation: Functional Coating Shell Formulation

The key breakthrough of this research lies in the design and validation of a specialized coating shell formulation for encapsulating nitrogen fertilizers (e.g., urea). This shell is not merely a physical barrier but an intelligent material composed of an organic binder, functional minerals, and organic matter. Its design serves a dual purpose: first, to regulate the release rate of the core nitrogen, aligning it better with crop growth demands and reducing losses from premature release; second, the shell material itself possesses soil-improving potential.

A literature review underpins the scientific selection of formulation components: The organic binder (such as modified lignin, humic acid, or biopolymers) provides film-forming properties and certain slow-release characteristics, while itself being an excellent soil conditioner. Adding specific mineral components (e.g., diatomaceous earth, bentonite, or phosphate rock powder) can enhance the shell’s mechanical strength, adsorption capacity, and supply secondary and micronutrients. This “organic-inorganic” composite shell degrades gradually in the soil. While releasing nutrients, its organic portion helps increase the soil organic carbon pool and improve aggregate structure, thereby tangibly enhancing soil fertility and achieving the integration of “fertilizing” and “nurturing the soil.”

II. Core Equipment: Advantages of the Disc Granulator Application

The selection of the disc (pan) granulator as the core equipment for this coating process is based on its unique working principle and process compatibility. The disc granulator utilizes the rotational motion of an inclined pan to induce rolling of the material under the combined effects of gravity, centrifugal force, and friction. This characteristic makes it particularly suitable for a layering coating granulation process.

In the described process, nitrogen fertilizer particles (the core) are continuously fed into the rotating disc. Subsequently, the prepared coating slurry (containing organic binder, fine mineral powder, etc.) is uniformly applied to the surface of the rolling core particles via spraying or dripping. Under the continuous, gentle tumbling action provided by the disc, the water in the slurry gradually evaporates or solidifies via the binder, and a uniform composite shell layer gradually deposits and coats the core surface, forming composite particles with a “core-shell” structure. The advantages of the disc granulator include its intuitive operation, ease of controlling particle size, suitability for small to medium-scale flexible production, and, compared to some high-pressure granulation methods, greater friendliness to temperature-sensitive bioactive organic components.

III. System Design and Calculation: An Engineering Path from Process to Equipment

To ensure the scalability and economic viability of this technology, the study proposes a complete algorithm for the calculation and design of the granulation unit. This algorithm is a systematic engineering framework comprising four main stages:

1. Coating Process Calculation: Based on the target nutrient release profile and the properties of the core and shell materials, determine key process parameters such as coating slurry solid content, spray rate, disc rotation speed, inclination angle, and drying conditions.

2. Constructive Calculation of the Disc Granulator: According to the processing capacity, target particle size, and material properties, calculate and determine the key dimensions of the granulation disc (diameter, rim height, inclination angle), drive power, and structural strength.

3. Optimization Calculation of the Granulation Unit: Simulate and optimize the granulator together with upstream (batching, mixing) and downstream (drying, cooling, screening) equipment as an integrated unit to achieve minimum energy consumption, maximum output, and highest product qualification rate.

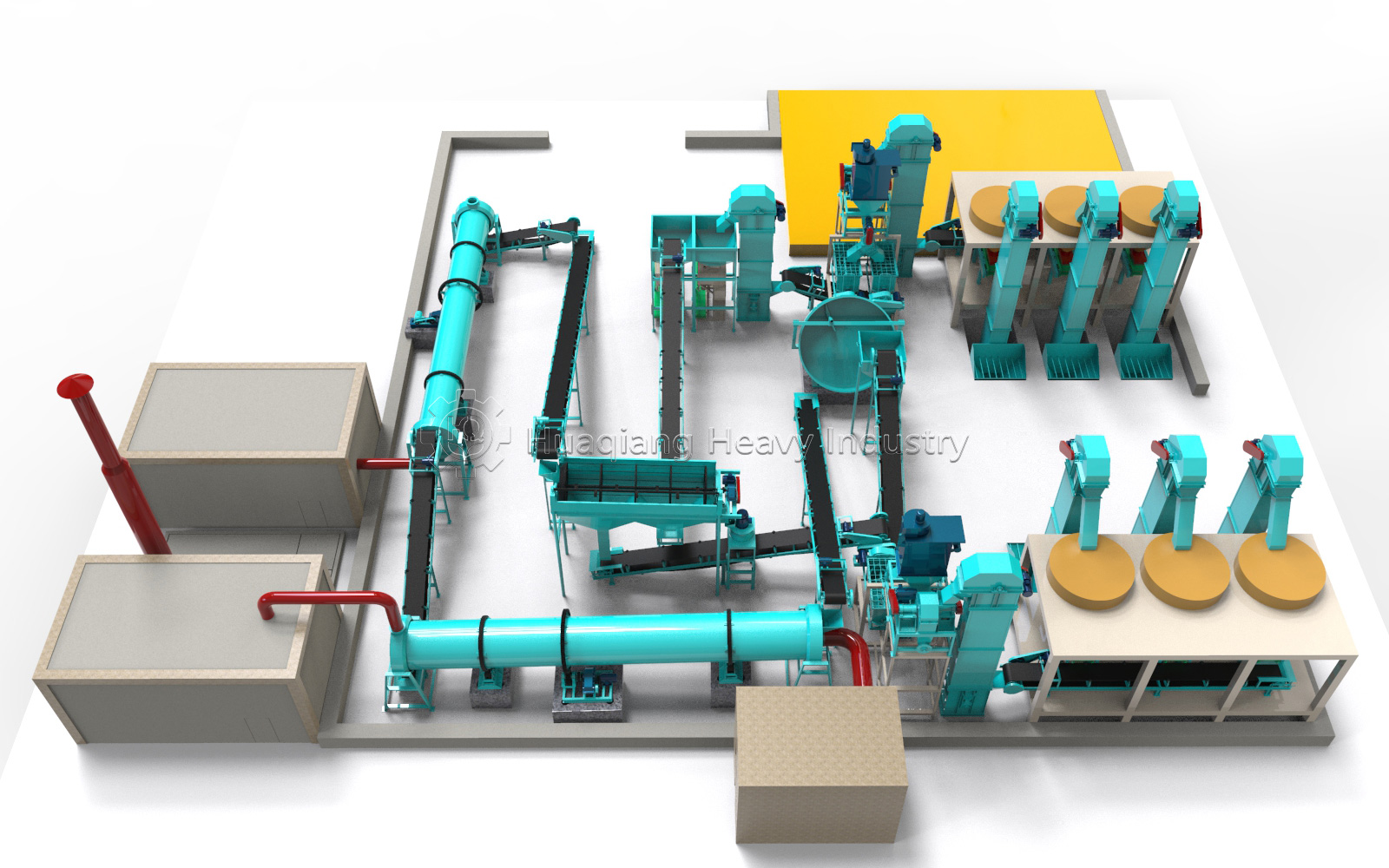

4. Design Stage of the Granulation Unit: Complete the detailed layout of mechanical equipment, design of the automated control system, and plant layout planning, providing a blueprint for actual production line construction.

IV. Structural Characterization and Efficacy Evaluation

To verify the coating effectiveness and product quality, the study conducted in-depth characterization of the produced “core-shell” structured granules. X-ray diffraction (XRD) was used to analyze the crystal structure of the granule shell, confirming the presence and distribution of functional minerals. Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDX) was employed to observe the micromorphology and cross-sectional structure of the granules and determine their elemental composition, visually confirming the formation of a uniform, dense coating layer and a clear interface between the core and shell.

These characterization results, combined with agronomic data from laboratory and pot experiments, provide solid evidence for evaluating the effectiveness of this new method for producing organo-mineral fertilizers. Preliminary results indicate that, compared to uncoated controls, the coated fertilizer can significantly reduce nitrogen leaching, extend the fertilizer effect duration, and, while maintaining equal or slightly higher crop yield in the current season, produce positive residual effects on soil organic matter content and microbial activity.

This study systematically elaborates on a method for efficiently producing high-performance organo-mineral fertilizers using a disc granulator based on innovative composite coating technology. From the design of the functional shell formulation and the selection and calculation of core equipment to the characterization of the granule structure, a complete technical scheme is formed. This technology not only provides an effective engineering solution for improving nitrogen use efficiency and reducing non-point source pollution but also extends mere nutrient supply to soil improvement through the introduction of the organic-inorganic composite shell, aligning with the long-term needs of green and sustainable agricultural development. In the future, through further large-scale field validation and cost-benefit analysis, this technology holds promise for contributing significantly to the upgrading of the fertilizer industry and the development of precision agriculture.

Conclusion: Integrating Granulation Technologies for Sustainable Fertilizer Production

In summary, this research presents a comprehensive methodology for producing high-performance organo-mineral fertilizers through innovative fertilizer granulation technology. Utilizing a disc granulation production line for coating applications offers a versatile and efficient approach to creating “core-shell” structured products. While the disc granulator excels in layering coating processes, it’s important to recognize that other npk manufacturing process technologies, such as rotary drum granulation or fertilizer compaction via roller press granulator production lines, may be better suited for different formulations or scales of production within a complete npk production line.

Future integration of this coating technology with existing npk fertilizer production technology infrastructure, including rotary screener units for precise classification, could further optimize system efficiency. The choice between drum granulation, disc granulation, and fertilizer granules compaction methods should be guided by specific product requirements and operational objectives. This work underscores that advancing fertilizer granulation technology is not a one-size-fits-all endeavor but rather a strategic selection and integration of processes. By combining functional coating science with appropriate engineering solutions like the fertilizer compaction machine or granulation lines, we can develop next-generation fertilizers that truly synergize enhanced nutrient efficiency with tangible soil health benefits, paving the way for more sustainable and productive agricultural systems globally.