In the oil palm industry’s production chain, oil palm empty fruit bunches (OPEFB), once considered a waste product requiring disposal, have now become a valuable resource in sustainable agriculture due to their rich nutritional advantages. As an organic waste rich in nitrogen, phosphorus, potassium, calcium, magnesium, and other nutrients, oil palm empty fruit bunches, through various methods such as composting and biochar conversion, demonstrate unique value in improving soil quality and promoting crop growth, providing an effective path for the green transformation of agriculture.

The utilization of oil palm empty fruit bunches as fertilizer has diverse applications, adapting to different agricultural production needs. Composting is the most common method, where empty fruit bunches are mixed with manure or palm oil mill effluent and fermented to produce a nutritionally balanced organic fertilizer, fully activating its nutrient potential. Pyrolysis technology can convert empty fruit bunches into porous biochar. This special material not only significantly improves soil fertility, with particularly outstanding effects on peat soils, but also promotes nutrient absorption by crops. Furthermore, potassium carbonate extracted from the ash of empty fruit bunches is a key ingredient in liquid fertilizers, enabling precise nutrient recovery; untreated empty fruit bunches can also be directly applied as mulch or mixed into the soil, continuously improving soil properties through natural decomposition.

The benefits of this organic waste to soil and plants are multifaceted. At the soil level, it effectively increases the nutrient content and organic carbon content of the soil, fundamentally improving soil structure, reducing compaction, and enhancing soil water and nutrient retention capacity. More importantly, it provides a favorable living environment for soil microorganisms and beneficial animals, activating the vitality of the soil microbial community and improving the stability of the soil ecosystem. For crops, these improvements ultimately translate into growth momentum, especially at higher application rates or in combination with other treatments, significantly promoting the growth of oil palm and other crops, improving yield and quality, while reducing reliance on synthetic fertilizers and lowering the risk of agricultural non-point source pollution.

Of course, some precautions should be considered when using oil palm empty fruit bunches as fertilizer. Its most significant characteristic is the slow release of nutrients. While it provides long-term nutrient supply, it may not meet the rapid nutrient needs of crops at specific growth stages. At the same time, single-component empty fruit bunch fertilizer often fails to provide balanced nutrition and usually requires supplementation with inorganic fertilizers to fully meet the nutritional needs of crops. Furthermore, due to its high lignin and wax content, unprocessed empty fruit bunches are difficult to handle and require pretreatment methods such as composting and pyrolysis to improve utilization efficiency.

Overall, oil palm empty fruit bunches, with their diverse utilization methods and significant improvement effects, have become a sustainable soil amendment with both ecological and economic value. The rational development and utilization of this valuable resource can not only solve the problem of disposing of by-products from the oil palm industry but also promote the transformation of agricultural production towards a low-carbon, environmentally friendly, and efficient direction, injecting new vitality into ensuring food security and ecological balance.

Integrating OPEFB into Modern Manufacturing Systems

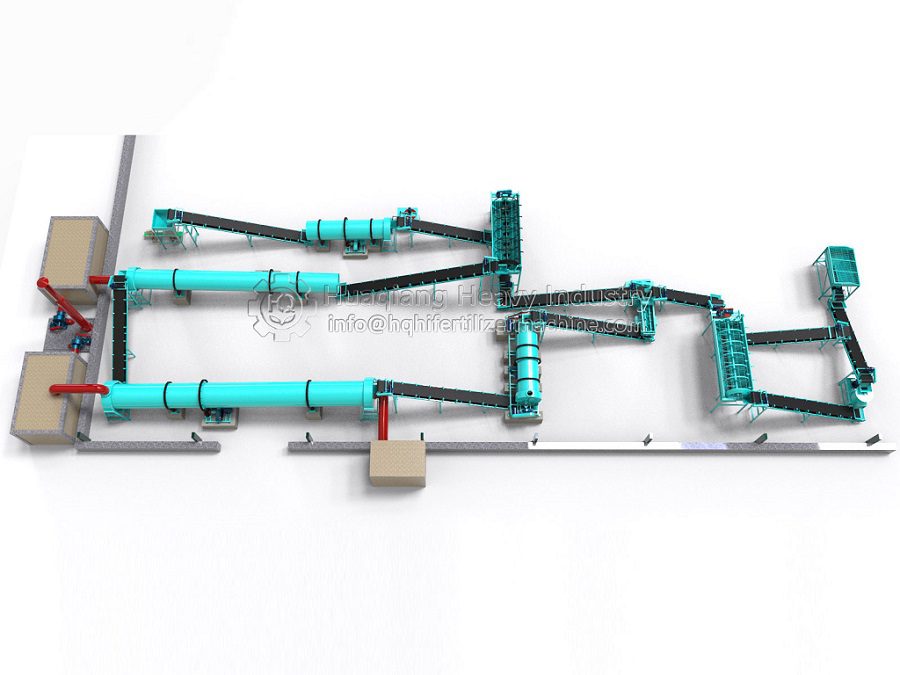

The uses of oil palm empty fruit bunch (OPEFB) as a sustainable fertilizer resource are maximized through systematic industrial processing. To transform this raw organic waste into a consistent, market-ready product, it must be integrated into a complete organic fertilizer manufacturing system.

The process begins with efficient decomposition, often accelerated by advanced fermentation composting turning technology to produce stable compost. This processed OPEFB compost then becomes the primary feedstock for a professional organic fertilizer production line. The core stage of organic fertilizer production granulation shapes the material into uniform pellets. Manufacturers can choose specialized equipment like an organic fertilizer disc granulation machine within a dedicated disc granulation line, or opt for versatile solutions such as a new type two in one organic fertilizer granulator or a comprehensive organic fertilizer combined granulation production line. These systems are designed to handle the fibrous nature of OPEFB, efficiently converting it into a high-value, easy-to-apply fertilizer that fulfills its potential in sustainable agriculture.Therefore, the true value of OPEFB is unlocked not just at the field level but through its seamless incorporation into sophisticated production lines that ensure quality, consistency, and scalability for the global organic fertilizer market.