Market Positioning and Regional Selection

Establishing a fertilizer company begins with clear market positioning and target region selection. In developed markets like Europe and America, consumers prefer environmentally friendly products, making organic fertilizer factory a viable option focused on sustainable agricultural products. In developing regions of Asia and Africa, NPK fertilizers hold greater market potential due to their efficiency and cost-effectiveness. Investors should choose appropriate product directions based on local agricultural structures and crop types.

Production Equipment Investment Planning

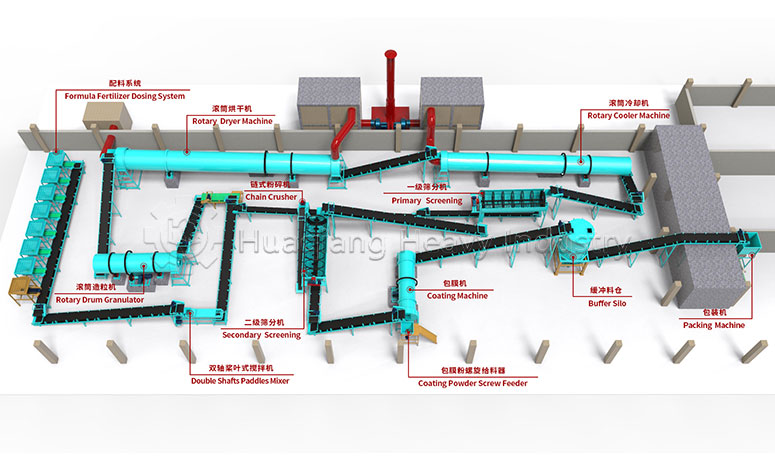

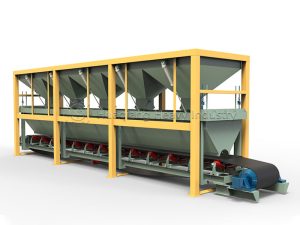

Fertilizer production equipment forms the core of company operations. Basic fertilizer processing machine includes crushers, mixers, and granulators. For NPK fertilizer production, specialized NPK fertilizer production technology equipment is required, such as rotary drum granulators and automatic batching systems. Complete fertilizer manufacturing plant equipment investments range from hundreds of thousands to millions of dollars, depending on automation levels and production scale. Organic fertilizer machinery price is generally lower than traditional fertilizer equipment, but requires consideration of special process equipment like composting fermentation systems.

Equipment Selection Recommendations

Small enterprises can start with basic equipment and gradually expand production lines. NPK fertilizer production price is influenced by multiple factors including raw material costs, energy prices, and equipment efficiency. Choosing energy-saving equipment and automated control systems can significantly reduce long-term operational costs.

Regulatory Compliance Requirements

Regulatory requirements vary significantly across regions. In the European Union, compliance with Regulation (EU) 2019/1009 is mandatory, with strict requirements on contaminant limits and labeling. The United States requires registration with EPA and state agricultural departments. In Southeast Asian countries like Indonesia, foreign investments must meet minimum investment thresholds and obtain relevant import permits. Establishing a comprehensive compliance system is fundamental for long-term company development.

Technological Innovation and Sustainable Development

Modern fertilizer companies should focus on technological innovation, particularly in NPK fertilizer production technology. By optimizing formulations and processes, nutrient utilization efficiency can be improved while reducing environmental pollution. Meanwhile, establishing organic fertilizer production lines aligns with global sustainable development trends. Combining traditional fertilizers with organic products to provide comprehensive nutrition solutions represents the industry’s future direction.

Operations and Market Strategy

Successful fertilizer companies need to establish complete supply chains and distribution networks. In agriculturally developed regions, direct partnerships with agricultural cooperatives and large farms can be established. In developing countries, adaptation to price-sensitive market characteristics and provision of cost-effective products are essential. Digital marketing and technical services also serve as important means to enhance competitiveness.

Establishing a fertilizer company is a systematic project requiring comprehensive consideration of technical, market, and regulatory factors. Through precise market positioning, reasonable equipment investment, strict compliance management, and continuous technological innovation, new entrants can find their development space in the highly competitive fertilizer industry. Whether choosing traditional NPK fertilizer production or emerging organic fertilizer fields, deep understanding of local market demands and policy environments is essential.

Strategic Equipment Investment for Fertilizer Production Success

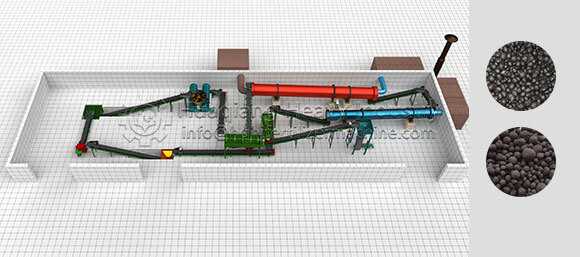

Establishing a successful fertilizer manufacturing operation requires strategic equipment selection tailored to market demands. For NPK production, the npk fertilizer production line typically integrates an npk blending machine with advanced granulation technology. Among various fertilizer granulation processes, the disc granulator machine offers excellent efficiency in disc granulation production line configurations, while the double roller press granulator provides alternative compaction granulation. The complete fertilizer manufacturing plant equipment package significantly impacts both initial organic fertilizer machinery price and long-term NPK fertilizer production price.

For organic operations, the bio organic fertilizer production line begins with pre-composting processing equipment and windrow composting machine systems, where the windrow machine facilitates efficient fermentation before material moves to the organic fertilizer production line for final processing. Whether selecting a complete npk fertilizer line or specialized disc granulator units, investors should balance equipment capabilities with production targets. The optimal fertilizer granulator choice ultimately depends on raw material characteristics, production scale, and product quality requirements, ensuring competitive advantage in both organic and mineral fertilizer markets.