In the forming process of organic and compound fertilizers, disc granulators and double roller press granulators, with their different shaping logics, have become organic fertilizer granulators adaptable to different raw materials and needs. They not only meet the requirements of diverse fertilizer forms but also make the granulation process more aligned with actual production scenarios.

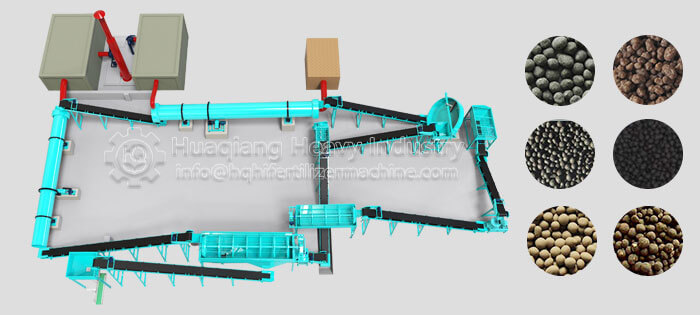

The core of disc granulators is “rolling agglomeration.” This method is more suitable for organic raw materials with moderate moisture content, such as well-rotted cow manure and straw substrates. The formed granules have a smooth appearance and moderate density, which not only promotes microbial survival (especially suitable for bio-organic fertilizers) but also facilitates subsequent storage and mechanized application, preventing clumping.

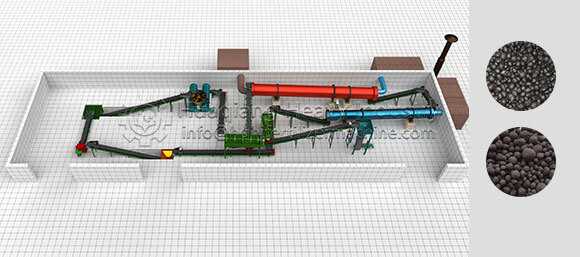

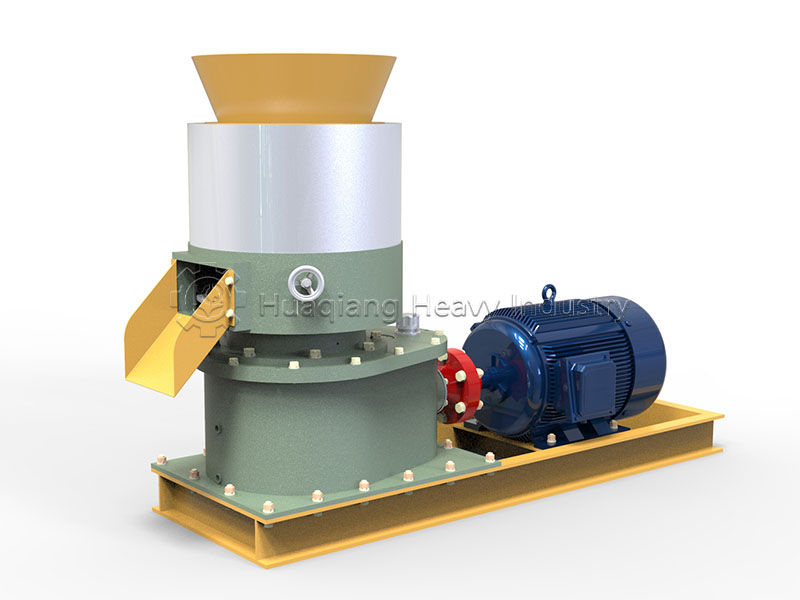

Double roller press granulators, on the other hand, follow a “pressure shaping” approach. The advantages of this process are that it requires no binder, has high forming efficiency, and produces granules with high hardness and strong moisture resistance. It is particularly suitable for granulating high-concentration fertilizers or dry raw materials, solving the problems of these materials being difficult to agglomerate and prone to scattering.

For those seeking granule roundness and bioactivity, disc granulators are the preferred choice; for those prioritizing high hardness, dry material forming, and binder-free processes, double roller press granulators are more suitable. These technologies address the pain points of fertilizer forming from different perspectives, providing flexible support for the diverse needs of fertilizer production.