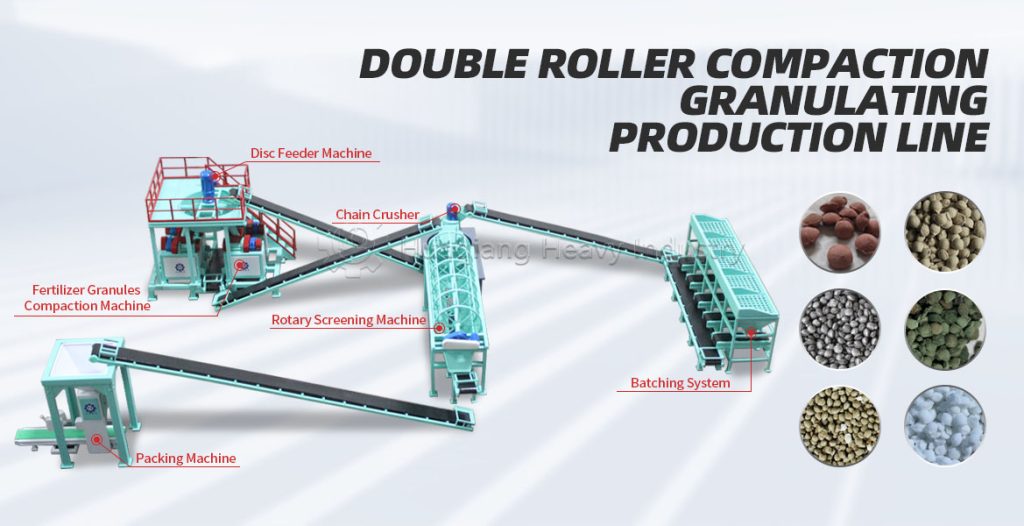

In the field of granular product manufacturing, traditional granulation often faces challenges such as insufficient particle strength, uneven particle size, high energy consumption, and failure to meet environmental standards. Roller press granulation production lines, with their optimized design, have become the preferred solution to these problems, widely adaptable to the granulation needs of various industries, including fertilizers, chemicals, and feed.

Traditional fertilizer granulation equipment suffers from limited raw material adaptability and low finished product yield. This is especially true for organic fertilizer granulation, where complex raw materials and fluctuating moisture levels can lead to sticking and clumping. The double roller press granulator utilizes a drying-free, room-temperature granulation technology, eliminating the drying process and resulting in lower energy consumption. It can handle a variety of powder raw materials with moisture content ranging from 8% to 20%, stably granulating both organic fertilizer fermentation materials and special chemical powders.

Balancing environmental protection and efficiency is its core advantage. The dust and noise pollution problems of traditional granulation can be solved by the fully enclosed structure and dust collection device of this production line, effectively controlling dust emissions. Combined with a variable frequency speed control motor and PLC intelligent control system, it enables automated continuous production, reducing manual intervention, improving efficiency, and minimizing operational errors.

Its industry adaptability is extensive: the fertilizer industry can produce organic-inorganic compound fertilizer granules, ensuring uniform nutrient distribution; the chemical industry can process heat-sensitive and corrosive raw materials, preventing deterioration; and the feed industry can produce high-strength granules of additives, preventing breakage during transportation.