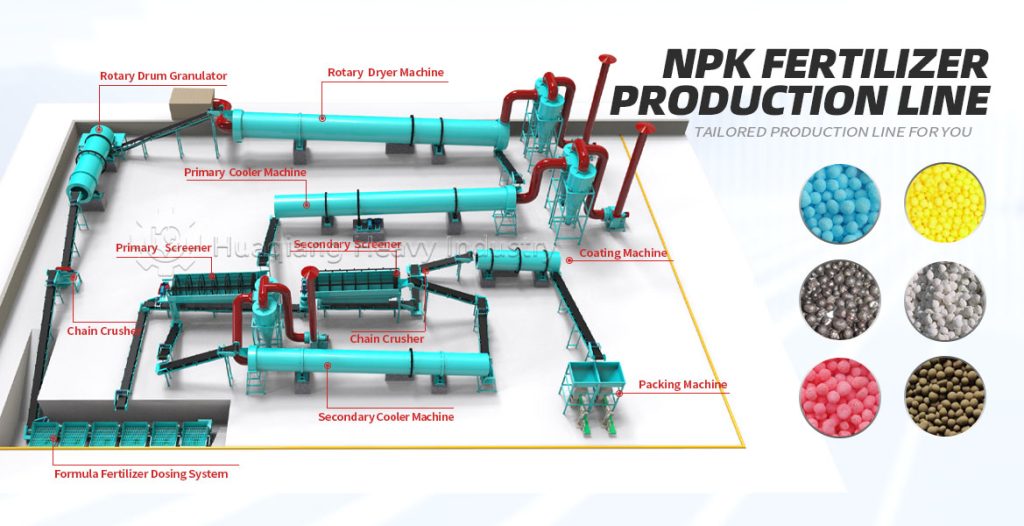

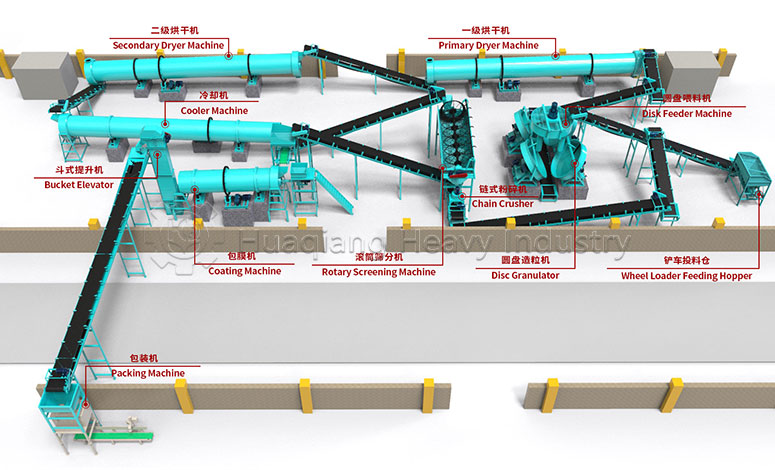

The core value of NPK compound fertilizer lies in the balanced supply of the three major nutrients: nitrogen (N), phosphorus (P), and potassium (K). The selection of raw materials directly determines its nutrient content, fertilizer efficiency, and applicable scenarios. Production requires an NPK fertilizer production line, precisely matching nitrogen, phosphorus, and potassium source raw materials and a small amount of auxiliary materials according to nutrient requirements.

Nitrogen source raw materials are diverse and highly adaptable. Urea has a nitrogen content of 46%, and its nutrients are pure and easily absorbed, making it the first choice for high-nitrogen compound fertilizers; ammonium chloride is low in cost, and ammonium sulfate can supplement sulfur, respectively suitable for chlorine-loving and sulfur-tolerant crops; calcium ammonium nitrate combines nitrogen and calcium supplementation functions, is safe to use, and is suitable for fruit and vegetable cultivation.

Phosphorus source raw materials mainly come from phosphate rock processing, requiring consideration of both effectiveness and stability. Monoammonium phosphate and diammonium phosphate are the mainstream options; the former has a high phosphorus content and good water solubility, while the latter has excellent nitrogen-phosphorus synergy; superphosphate and triple superphosphate are cost-effective, the former contains sulfur, and the latter has a higher phosphorus concentration, and can be selected according to cost and crop needs.

Potassium source raw materials are divided into chloride and sulfate types. Potassium chloride has a high potassium content and low cost, suitable for field crops, but prohibited for chlorine-sensitive crops; potassium sulfate is suitable for chlorine-sensitive crops and supplements sulfur, and is mostly used for fruits, vegetables, and cash crops; potassium nitrate combines nitrogen and potassium nutrients, acts quickly, and is suitable for critical growth stages of crops.

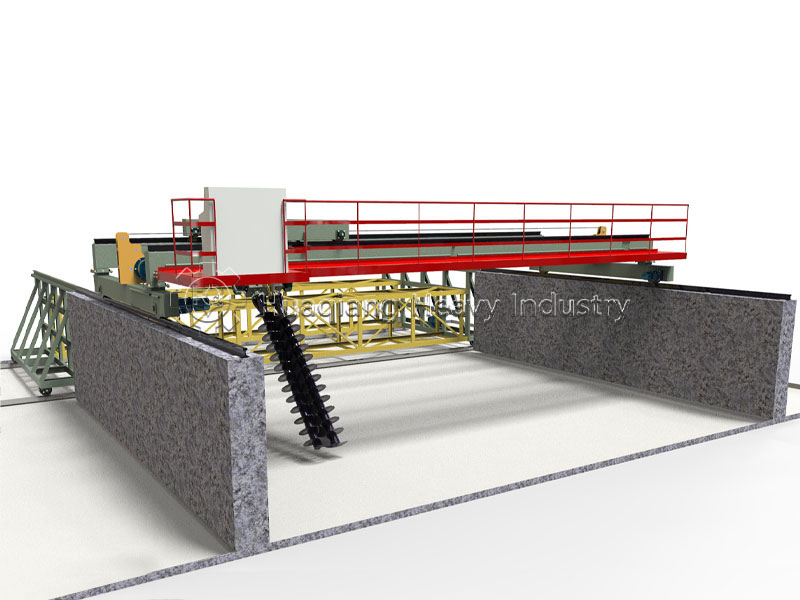

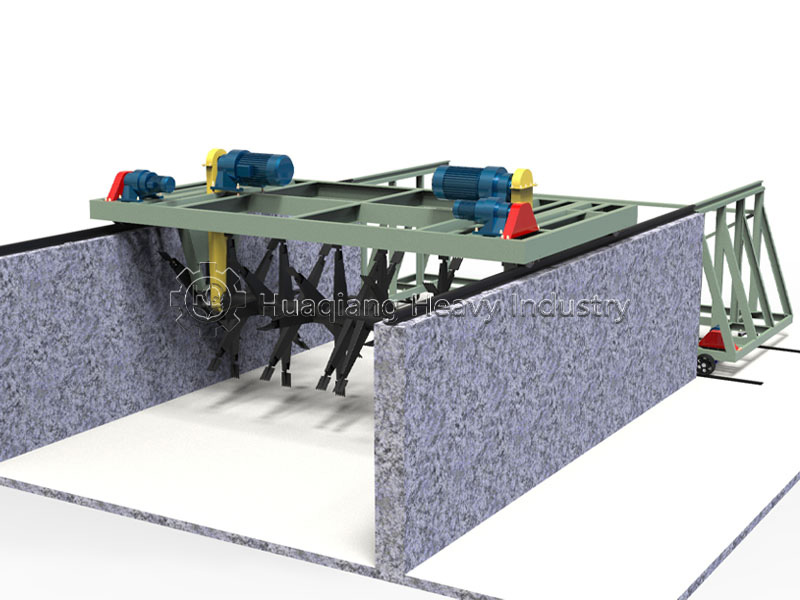

Auxiliary materials need to include binders and fillers to improve the molding and stability of the fertilizer. During processing, the main and auxiliary materials are thoroughly mixed using a fertilizer mixer, and specialized fertilizer production equipment is used to ensure uniformity.