In modern agriculture, nitrogen fertilizer is like an “energy drink” for crops. However, not all nitrogen fertilizers can be easily formed into user-friendly shapes. One efficient and economical nitrogen source—ammium chloride—has long faced a unique challenge: it is notoriously difficult to turn into granules.

Why Make Granules?

Imagine two types of fertilizer: one is a fine powder that scatters with the wind and applies unevenly; the other consists of uniform pellets that can be spread precisely by machinery. Granular fertilizers are not only easier to use and reduce waste but also allow nutrients to be released more steadily, benefiting both the environment and the crops.

Nitrogen fertilizers like urea and ammonium sulfate can be granulated relatively easily. But ammonium chloride is an exception. Due to the strong ionic bonds between its ammonium and chloride ions, traditional tumble-granulation methods are largely ineffective. Factories mainly use “extrusion granulation”—forcing the material through a die, similar to pressing noodles. This method, however, is costly, energy-intensive, and prone to equipment corrosion. Consequently, ammonium chloride is usually sold in powder form, limiting its application.

A Breakthrough in Finding a “Binder”

Scientists have been searching for a “binder” that can make ammonium chloride powder “coalesce” into granules. Through extensive experimentation, they discovered that a substance called polyaluminum chloride (PAC) works remarkably well.

Polyaluminum chloride is commonly used in water treatment to coagulate and settle impurities. It was this very “coagulating” property that caught the researchers’ attention. Experiments showed that when powdered PAC is mixed with ammonium chloride, along with a small amount of urea as an “auxiliary agent,” the mixture in a disc granulator at room temperature can quickly form uniform, round pellets.

The Science Behind It

This process relies on three key mechanisms:

Neutralizing Electrostatic Charge: Tiny ammonium chloride particles repel each other due to similar surface charges. PAC releases a multitude of positive ions in water, which neutralize the negative charges on the particle surfaces, eliminating repulsion.

Building Bridges: The PAC molecule has numerous active groups that can simultaneously “grab” multiple ammonium chloride particles, forming strong “particle-polymer-particle” bridges between them.

Urea’s Assistance: Urea and ammonium chloride can form a stable inclusion structure, further strengthening the internal bonds within the pellet and significantly improving granulation efficiency.

After optimization, the research team identified an optimal formula: a mixture of ammonium chloride, urea, and PAC in a mass ratio of approximately 74:18:8. Pellets produced using this method achieved an average hardness of about 20 Newtons, fully meeting practical requirements.

Significance for Sustainable Agriculture

This breakthrough not only solves the granulation challenge of ammonium chloride but also holds important environmental significance. Granulated ammonium chloride can reduce nutrient loss during application, improve fertilizer use efficiency, and thereby lower the risk of pollution to water bodies and soil.

From laboratory innovation to field application, this research demonstrates how scientific approaches can solve practical agricultural problems. It shows us that even seemingly simple “shaping” issues can contribute significantly to more efficient and environmentally friendly agricultural production.

Granulation: The Bridge Between Chemistry and Application

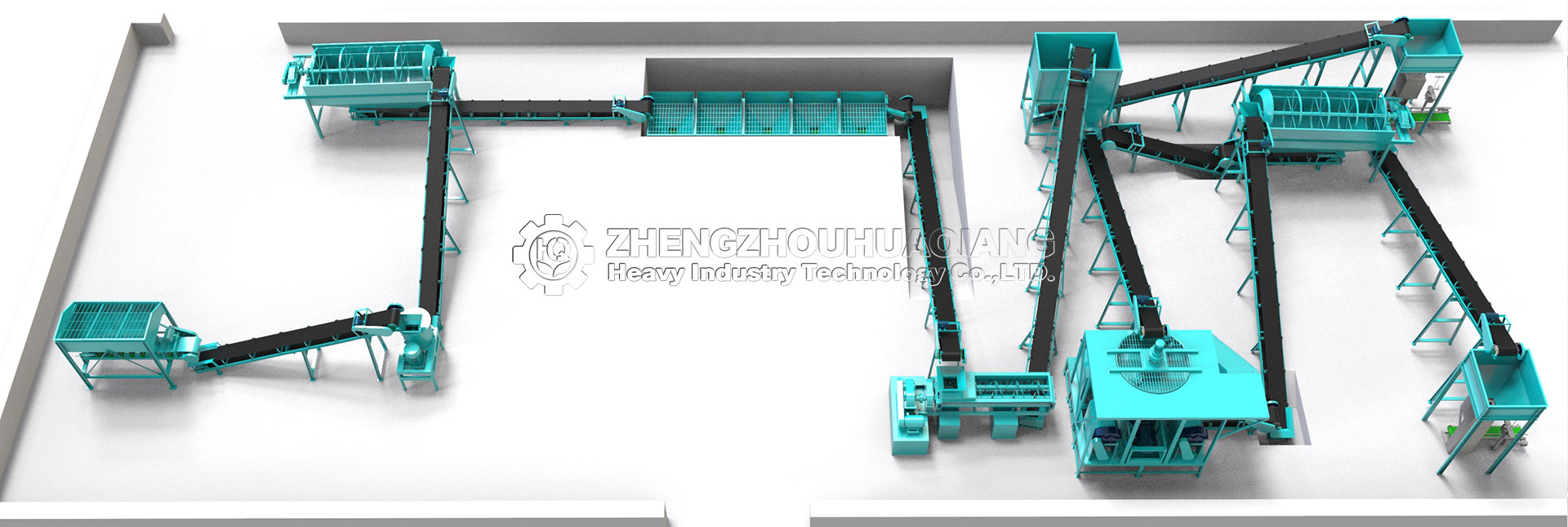

The successful granulation of challenging materials like ammonium chloride underscores the sophistication of modern fertilizer granulation technology. This breakthrough represents a specialized application within the broader spectrum of dry granulation processes, where fertilizer granules compaction is achieved without added moisture, often using a fertilizer compaction machine. This approach stands in contrast to wet methods commonly used in a standard npk manufacturing process, such as those employing a rotary drum granulator.

The development of such specialized binders and techniques highlights the ongoing innovation within professional fertilizer manufacturing equipment. Whether integrated into a complete npk production line for compound fertilizers or used for single-nutrient products, advanced fertilizer processing machine technology is crucial. This includes equipment like the roller press granulator production line designed for dry compaction. The evolution of fertilizer production machine capabilities ensures that even difficult-to-formulate nutrients can be delivered in efficient, user-friendly, and environmentally responsible forms, enhancing the precision and sustainability of global agriculture.