Bulk blended fertilizers (also known as BB fertilizers), with their advantages of flexible formulas, balanced nutrients, and low production costs, are widely used in modern agricultural production. Although their production process does not require complex chemical reactions, it relies on a complete set of specialized equipment to achieve standardized operations in raw material proportioning, mixing, and packaging, ensuring stable product quality. A standard bulk blended fertilizer production line mainly consists of four categories of core equipment, working together to complete the entire process from raw material processing to finished product delivery.

The automatic batching system is the “precise heart” of bulk blended fertilizer production, directly determining the accuracy of the fertilizer nutrient ratio. This system usually consists of raw material silos, automatic feeding devices, weighing hoppers, and an electrical control system. It is generally equipped with 4-5 stainless steel raw material silos, which can store raw materials such as nitrogen, phosphorus, potassium, and trace elements separately. The silos are equipped with partitions to prevent cross-contamination. Through weighing sensors and an intelligent control system, the equipment can achieve two-stage feeding (fast and slow), automatically switching to fine feeding mode when approaching the set weight, accurately completing the quantitative proportioning of various raw materials. The proportioning error can be controlled within a very small range, ensuring uniform nutrient distribution in each batch of fertilizer.

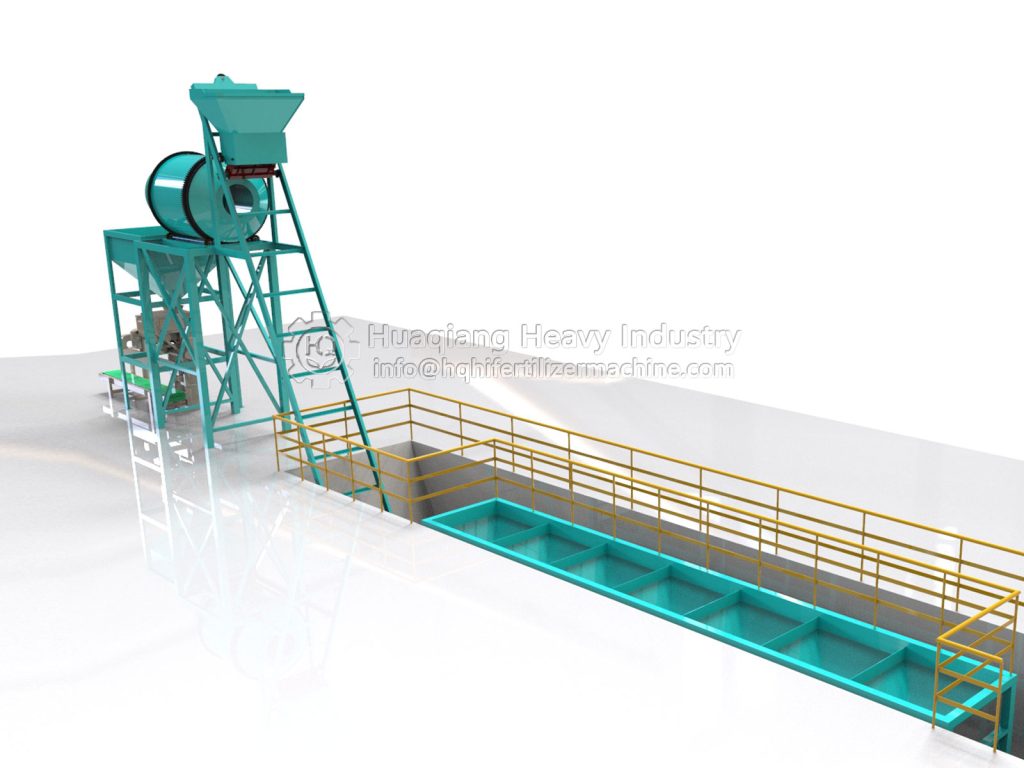

The lifting and mixing device is crucial for achieving uniform blending of raw materials. The proportioned raw materials are unloaded into the lifting machine via a guiding device. The commonly used bucket elevator can stably transport the raw materials into the mixer. BB fertilizer blenders mostly use a drum type, with the mixing time set by the central control system. A special internal spiral structure is used to achieve three-dimensional mixing of the raw materials, ensuring that different nutrient raw materials are fully blended, preventing stratification and segregation, while also preserving the original granular form of the raw materials, thus ensuring the effectiveness of the fertilizer application.

The automatic quantitative packaging system is responsible for the standardized packaging of finished products, improving production efficiency. This system includes a packaging scale, conveyor belt, and automatic sewing machine. After the uniformly mixed fertilizer enters the packaging machine hopper, the quantitative packaging scale dynamically weighs the fertilizer using imported sensors, automatically filling the bags according to preset specifications (mostly 50kg/bag). The bags are then transported to the sewing station for sealing. The entire system achieves automated operation from feeding and weighing to sewing, improving packaging speed and ensuring accurate weight for each bag of fertilizer.

In summary, the automatic batching system, lifting and mixing device, and automatic quantitative packaging system together constitute the bulk blended fertilizer line. Each piece of equipment performs its specific function and works in conjunction with the others: the batching system ensures accuracy, the mixing device guarantees uniformity, and the packaging system improves efficiency. All three are indispensable. This equipment system not only simplifies the production process of blended fertilizers and reduces errors caused by manual intervention, but also ensures the stability and standardization of product quality. This allows blended fertilizers to fully utilize their advantages of flexible formulation and balanced nutrients, providing reliable equipment support for modern large-scale and refined agricultural production, and contributing to improved agricultural quality and efficiency, as well as increased farmer income.