The market prospect of organic fertilizer is broad, and more and more medium and large farms choose to process livestock manure into organic fertilizer for sale. The most important step in the production of organic fertilizer is the fermentation of organic raw materials. During the fermentation process, the raw materials need to be turned over so that the middle materials can be fully exposed to the air for fermentation and decomposition and water removal. Due to large-scale production, the processing capacity of organic raw materials is very large, and it is unrealistic to carry out manual flipping, which requires the use of flipping equipment. There are many types of flipping equipment on the market, and it is difficult to choose a suitable flipping equipment. This article simply describes the common tossing equipment and use scenarios on the market.

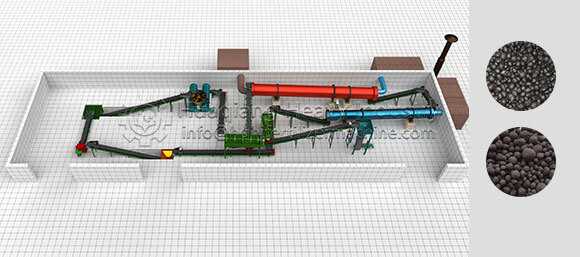

1.Simple Compost Turning Machine

Fermentation tanks need to be built, and with the help of mobile cars, it is possible to rotate between multiple fermentation tanks and reduce investment.

Tossing depth 0.8-1.8 meters, width 3-6 meters.

Can advance 1-2 meters per minute, the walking speed depends on the density of the material, the density is large, the walking speed is slow.

Application scenario: Daily organic raw material processing capacity of more than 20 tons, annual output of 6,000 tons of organic fertilizer. There is no need for manpower when the tilting machine is working.

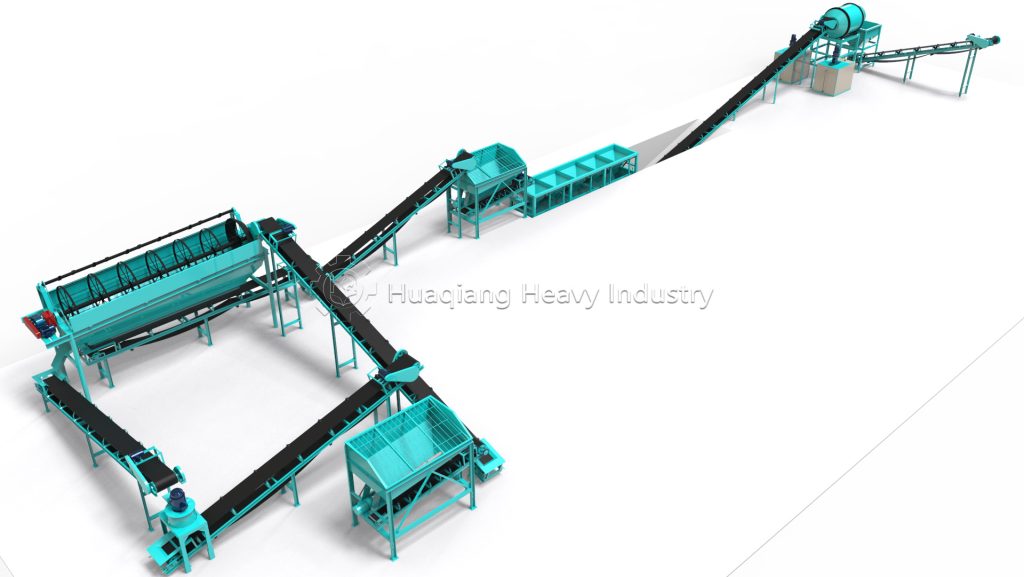

2.Wheel Type Windrow Compost Turning Machine

The requirements for the workshop are higher, the wall must be strong, and the indoor operation.

Flipping span up to 33 meters wide, depth up to 1.5-3 meters, suitable for deep flipping operations.

Application scenario: Daily organic raw material processing capacity of more than 30 tons, annual output of 10,000 to 20,000 tons of organic fertilizer. The tilting machine works automatically without manpower.

3.Double Screws Compost Turning Machine

Compared with the wheel type throwing machine, the double wheel disk as the name suggests is 2 roulette one operation, the efficiency is very high.

The requirements for the workshop are higher, the wall must be strong, and the indoor operation.

Flipping span up to 33 meters wide, depth up to 1.5-3 meters, suitable for deep flipping operations.

Application scenario: Daily organic raw material processing capacity of more than 30 tons, annual output of 10,000 to 20,000 tons of organic fertilizer. The tilting machine works automatically without manpower.

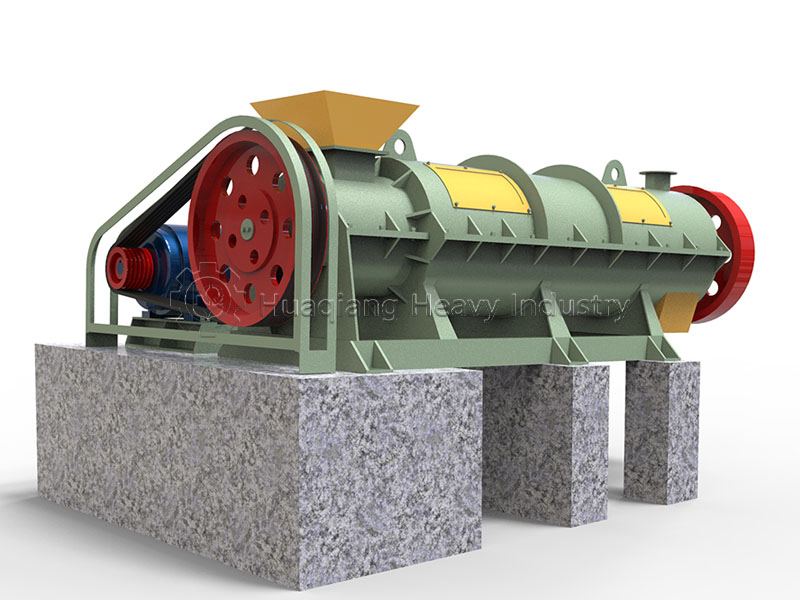

4. Chain Compost Turning Machine

Fermentation tanks need to be built, and with the help of the mobile car, it is possible to rotate between multiple fermentation tanks.

The walking speed is fast, the flipping depth can reach 2 meters, suitable for deep slot operation.

Equipped with a shifting machine to change the slot can realize the multi-slot operation of a flipping machine, saving investment.

Since the tilting plate is inclined, after each tilting, the material as a whole will move forward. The next time you stack the material, put it directly at the back of the field.

Application scenario: Small fermentation site, deep fermentation tank, daily organic raw material processing capacity of more than 30 tons, annual output of 10,000 to 20,000 tons of organic fertilizer. The tilting machine works automatically without manpower.

5.Crawler-type Turning Machine

No need to build a trough, just pile the fertilizer into strips. The stacking spacing is 0.8-1 meters, and the stacking height is 0.6-1.8 meters, which saves investment cost and is convenient for expansion.

The dump plane has a cockpit, and workers can isolate some of the odor when operating the machine.

Application scenario: Daily organic raw material processing capacity of more than 5 tons, annual output of 3,000 tons of organic fertilizer. When the tilting machine is working, a worker is required to operate the machine.