In the modern fertilizer production industry, the disc granulator acts like a skilled sculptor, meticulously shaping various raw materials into uniform, robust fertilizer pellets. As the core equipment in fertilizer production lines, it is not only suitable for granulating organic fertilizers, organic-inorganic compound fertilizers, chemical fertilizers, and biofertilizers, but also serves as an indispensable component in NPK fertilizer production technology.

When organic fertilizer produced through disc granulation lines is applied to soil, it significantly enhances organic matter content and increases soil organic nitrogen, improving soil structure. The advantages of this production system are clear: high pellet uniformity, effortless moisture control, and exceptional granule strength, laying a solid foundation for the entire NPK fertilizer production process.

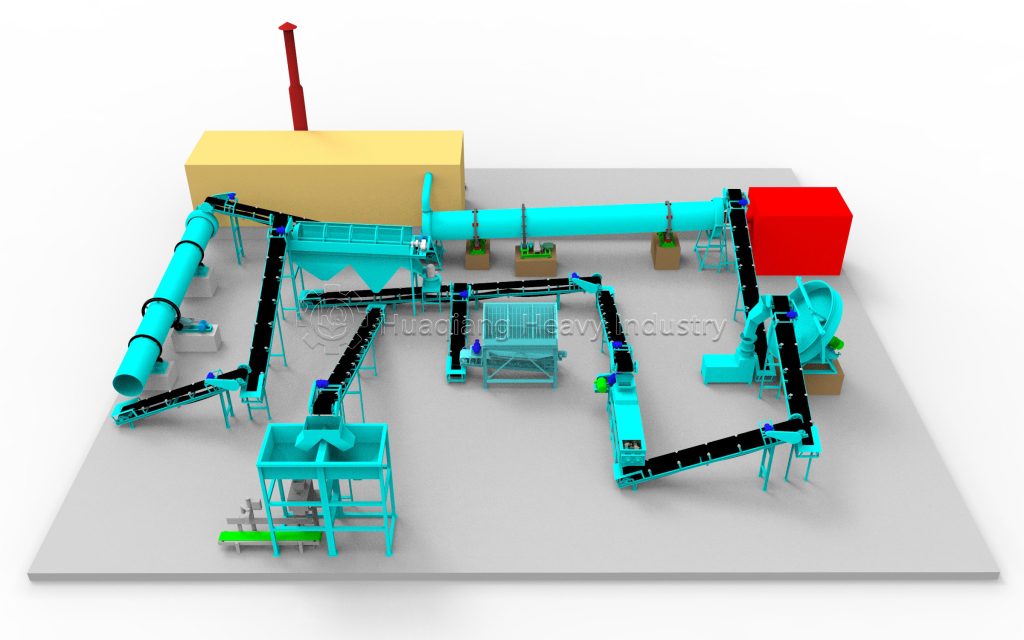

A complete disc granulation production line resembles a well-trained orchestra, with each device playing a unique role: horizontal mixers ensure thorough blending of raw materials; drum screening machines achieve precise classification; coating machines provide protective layers; multi-silo single-weigh static automatic batching systems enable accurate proportioning; and automatic packing machines complete the final step. The conductor of this orchestra is the highly efficient and reliable NPK fertilizer granulator.

Modern disc granulator designs incorporate innovative concepts: novel and rational structure, significantly reduced weight and height, and flexible, convenient process layout, making them particularly suitable for technical upgrades in existing fertilizer plants. The large-inclination disc body allows flexible adjustment through gaskets, coupled with unique disc treatment technology, ensuring smooth discharge without tearing. Unpowered combination scrapers automatically clean edges, while corner scrapers handle dead spots—these innovative designs result in finished pellets with uniform content and exceptional quality.

More importantly, disc granulation technology demonstrates unique advantages in the NPK fertilizer production process. By precisely controlling disc inclination and rotation speed, producers can easily adjust pellet size to meet the nutritional needs of different crops. This flexibility makes disc granulators the preferred equipment for compound fertilizer manufacturers, especially excelling in producing specialty formula fertilizers.

From raw material proportioning to finished product packaging, disc granulation production lines achieve fully automated control, not only improving production efficiency but also ensuring product quality stability. This is precisely the goal pursued by modern NPK fertilizer production technology: producing the most efficient fertilizers in the most economical way, providing strong support for global food security.