As a core piece of equipment in fertilizer production lines, the granulator’s operating status directly affects the efficiency and economic benefits of the entire production line. Mastering scientific fault diagnosis methods and systematic maintenance strategies can significantly extend equipment life, reduce unplanned downtime losses, and create continuous and stable production value for enterprises.

I. Common Fault Phenomena and Precise Diagnostic Procedures

1. Granulation Quality Issues

Symptoms: Uneven granules, insufficient strength, decreased pelletizing rate

Diagnostic Steps:

Check raw material ratio: Verify the accuracy of nitrogen, phosphorus, potassium, and binder proportions.

Check raw material moisture content: Take samples to determine moisture content; the normal range should be 25%-35%.

Analyze raw material fineness: Use a sieve analyzer to ensure that more than 80% of the raw material passes through an 80-mesh sieve.

Check granulation parameters: Verify key parameters such as disc tilt angle (35°-45°), rotation speed (20-30 rpm), etc.

Solutions:

If the raw material moisture content is abnormal, immediately adjust the drying or humidification system.

If the formula ratio is unbalanced, recalibrate the automatic batching system.

If the granulation parameters are improper, reset them according to the standard operating manual.

2. Equipment Mechanical Failures

Symptoms: Abnormal vibration, bearing overheating, abnormal noise in the transmission system

Rapid Diagnostic Methods:

Vibration Detection: Measure the bearing housing vibration using a vibration meter. Normal vibration should be less than 4.5 mm/s.

Temperature Monitoring: Detect the bearing temperature using an infrared thermometer. If it exceeds 80℃, immediate action is required.

Sound Localization: Use a stethoscope to pinpoint the source of abnormal noise.

Typical Case: A fertilizer plant’s granulator suddenly experienced severe vibration. Testing revealed:

Main bearing vibration reached 8.2 mm/s (exceeding the standard)

Bearing temperature reached 92℃ (severely exceeding the standard)

Disassembly and inspection revealed severe wear on the bearing rollers.

Root Cause: Lubrication system failure leading to insufficient lubrication in the bearing.

II. Systematic Maintenance and Upkeep System

Daily Maintenance Standards (Performed every shift)

Cleaning and Inspection:

Remove accumulated material from the inner wall of the granulation disc

Clean the screen blockage

Inspect the scraper wear

Lubrication Management :

Check oil levels at all lubrication points

Replenish with dedicated high-temperature grease

Record lubrication time and amount

Tightening Check:

Check anchor bolt tightness

Verify transmission component connection status

Confirm safety protection devices are intact

Preventive Maintenance Plan Weekly Maintenance Focus:

Thoroughly clean the equipment interior

Inspect wear parts for vulnerable components

Calibrate measuring instrument accuracy

Monthly Maintenance Items:

Comprehensive bearing inspection: clearance measurement, seal inspection

Transmission system verification: gear meshing clearance adjustment

Electrical system inspection: motor insulation test, wiring tightening

Quarterly Deep Maintenance:

Comprehensive equipment disassembly and inspection

Flaw detection of major components

Control system software upgrade

III. Intelligent Maintenance Technology Application Online Monitoring System Construction Sensor Deployment:

Vibration sensors: key bearing locations

Temperature sensors: motors, bearings, reducers Current Sensor: Main Drive Motor

Data Acquisition and Analysis:

Establish Equipment Health Database

Set Early Warning Thresholds

Achieve Trend Analysis and Prediction

Predictive Maintenance Practices Successful Case: A fertilizer company in Zhejiang Province, through the installation of an online monitoring system:

Provided early warning of main bearing failure 3 weeks in advance

Avoided 72 hours of unplanned downtime

Saved 150,000 yuan in maintenance costs

Reduced production loss by 300 tons

IV. Spare Parts Management Optimization Strategy Key Spare Parts Classification Management Category A Spare Parts (Key Spare Parts):

Main Drive Bearing

Gear Reducer

Pelletizing Disc Liner Inventory Strategy: Maintain 1-2 sets of safety stock

Category B Spare Parts (Important Spare Parts):

Scraper Assembly

Sealing Sleeves

Electrical Components Inventory Strategy: Maintain 3-6 months’ worth of usage

Category C Spare Parts (Common Spare Parts):

Standard Fasteners

Ordinary Sealing Rings

Lubricating Grease Inventory Strategy Omitted: Procurement on Demand

Supplier Management

Establish a list of qualified suppliers

Sign a rapid response agreement

Implement supplier performance evaluation

V. Personnel Training and Technology Transfer

Operator Capacity Building

Basic Training:

Equipment Structure and Principles

Standard Operating Procedures

Daily Inspection Points

Skills Enhancement:

Fault Diagnosis Methods

Emergency Handling Procedures

Maintenance Techniques

Establish a Knowledge Management System

Compile a Fault Case Database

Produce Maintenance Video Tutorials

Establish a Technical Exchange Platform

VI. Economic Benefit Analysis

After implementing systematic maintenance management:

Equipment failure rate reduced by 60%

Average repair time shortened by 45%

Spare parts inventory cost reduced by 30%

Equipment service life extended by 40%

Annual comprehensive benefits increased by 25%

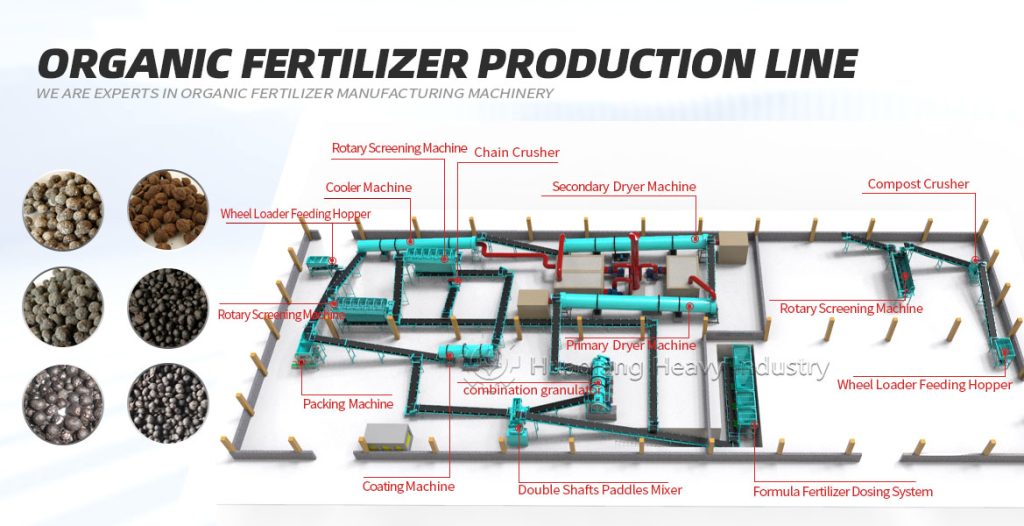

Holistic Maintenance for Diverse Granulation Systems

The rigorous maintenance principles outlined are universally applicable but must be adapted to the specific fertilizer production machine technology employed. Within the npk fertilizer manufacturing process (or the manufacturing of npk fertilizer), different granulation technologies are used. For the common wet fertilizer granulation processes involving a rotary drum granulator, maintenance focuses on liners, bearings, and the drive system. For dry granulation, a roller press granulator production line utilizing a fertilizer compactor requires specific attention to roller surface integrity, hydraulic pressure, and bearing temperature, as this fertilizer compaction method relies on high mechanical pressure.

Similarly, in an organic fertilizer disc granulation production line, maintenance revolves around the disc, scraper, and gearbox. The upstream fertilizer processing machine, such as a windrow composting machine providing feedstock, also has its own maintenance schedule. Therefore, a comprehensive strategy is required for the entire suite of fertilizer production machine units. Predictive maintenance and spare parts management for the core granulator—whether for fertilizer granules compaction or wet agglomeration—are critical investments that protect the substantial capital tied up in the npk manufacturing process and ensure uninterrupted, profitable operation.

Ultimately, viewing maintenance not as a reactive cost but as a proactive component of operational strategy is what transforms equipment management into a source of competitive advantage, ensuring reliability across all fertilizer production technologies.

The maintenance management of granulators is a systematic project that requires the organic combination of traditional experience and modern technology. By establishing a scientific fault diagnosis system, implementing refined maintenance, and applying intelligent monitoring technology, enterprises can not only effectively reduce downtime losses but also transform equipment management from a “cost center” to a “value creation center.” It is recommended that enterprises formulate appropriate maintenance strategies based on their own actual situation, and continuously optimize and improve them to ultimately maximize the value of equipment throughout its entire life cycle, providing a solid guarantee for the stable production and sustainable development of enterprises.