In an organic fertilizer production line, the crushing process is the “throat” of the entire line, directly determining raw material processing efficiency and final product quality. It is the core link between raw material pretreatment and subsequent fermentation and granulation processes. Whether it is agricultural waste such as livestock and poultry manure, straw, and mushroom residue, or organic raw materials such as restaurant waste and garden branches, they all require scientific crushing to achieve “fragmentation” and lay the foundation for subsequent processes.

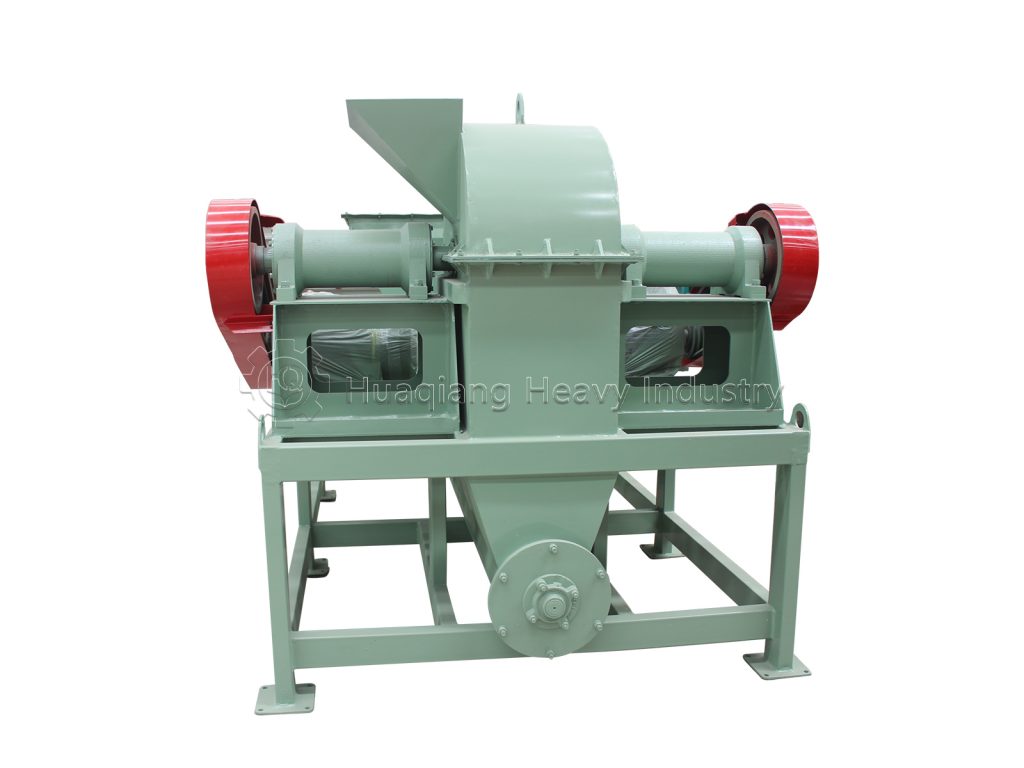

The primary task of the crushing process is to break down the raw materials’ physical structure and address the issues of uneven size and hardness among different raw materials. For example, unpulverized livestock and poultry manure may contain lumps such as straw residue and hair. If directly fed into the fermentation process, this can lead to imbalanced material permeability and localized anaerobic decay. Fibrous raw materials such as straw and branches require pulverization to reduce the particle size to 5-10 mm, making it easier for microorganisms to decompose the fiber structure and shortening the fermentation cycle. Currently, mainstream production lines mostly use cage crushers for fine grinding. For some large, hard raw materials, pre-screening is performed to remove oversized impurities before the raw materials enter the cage crusher, ensuring a particle size uniformity of over 90%.

Technical control in this process directly impacts the efficiency and product quality of the organic fertilizer production line. First, the particle size must be adjusted dynamically based on the raw material type: when processing high-moisture manure, the grinding fineness must be appropriately controlled to prevent clumping; when processing straw with a high lignin content, the particle size must be refined to improve composting maturity. Second, controlling dust and impurities during the grinding process is crucial. Reputable production lines install magnetic separation devices at the grinder inlet to remove metal impurities and bag filters at the discharge to meet environmental requirements and minimize equipment wear.

It is important to note that the finer the grinding process, the better. Excessive grinding not only increases energy costs but can also reduce the material’s aeration during fermentation, ultimately prolonging composting time. Industry practice demonstrates that crushing raw materials to a particle size that “clumps together in the hand and falls apart with a light squeeze” not only ensures microbial activity but also improves the yield rate in the subsequent granulation process. High-quality pulverization is a prerequisite for producing organic fertilizer products with uniform particles and meeting organic matter content standards. It is also a key step in promoting the efficient resource utilization of agricultural waste.