Introduction

Soil degradation is a global challenge affecting agricultural productivity and environmental sustainability. Fortunately, specific fertilizers can play a crucial role in soil restoration by replenishing nutrients, improving soil structure, and introducing beneficial microorganisms. This article explores how various fertilizers can address common soil problems including poor fertility, acidification, salinization, and contamination.

Types of Restoration Fertilizers

- Organic Fertilizers(composted straw, animal manure): Enhance soil organic matter content, improve soil aggregation, and increase water retention capacity while providing energy for soil microorganisms.

- Microbial Fertilizers(nitrogen-fixing bacteria, phosphate-solubilizing bacteria): Activate fixed nutrients in soil through microbial metabolism, suppress harmful pathogens, and restore soil microecological balance.

- Conditioning Fertilizers(humic acid, amino acid fertilizers): Regulate soil pH, alleviate acidification or alkalization, reduce heavy metal ion activity, and minimize crop uptake of contaminants.

- Mineral-based Fertilizers(zeolite, bentonite): Adsorb heavy metals and excess salts through their porous structure while improving soil aeration and permeability.

Restoration Methods for Specific Soil Issues

Poor Soil Fertility

Apply organic fertilizers as the primary treatment (2000-3000 kg per hectare) combined with chemical fertilizers containing nitrogen, phosphorus, and potassium. Incorporate deeply through plowing to gradually increase organic matter content. Avoid single-nutrient fertilization to prevent nutrient imbalance.

Soil Acidification (pH < 5.5)

Use humic acid fertilizers or alkaline conditioning fertilizers (50-100 kg per hectare) accompanied by irrigation to help neutralize soil acidity. Limit the long-term use of acidic chemical fertilizers like ammonium sulfate.

Soil Salinization (EC > 2 mS/cm)

Increase application of organic and microbial fertilizers. The organic acids released during decomposition help reduce salt concentration. Implement drip irrigation with frequent, small applications to leach surface salts while reducing chemical fertilizer usage.

Soil Compaction

Focus on organic fertilizers and crop residue incorporation. Apply 500-1000 kg of crushed straw per hectare combined with deep plowing to break up compacted layers. Reduce tillage intensity to preserve soil structure.

Heavy Metal Contamination

Apply humic acid fertilizers or mineral-based amendments to immobilize heavy metals through adsorption. Combine with specific microbial inoculants that promote the transformation of heavy metals into stable forms, reducing crop uptake risks.

Important Considerations

- Ensure organic fertilizers are fully composted to avoid introducing pathogens, pest eggs, or causing root burn

- Soil restoration requires long-term commitment – single applications have limited effects; continuous application over 2-3 growing seasons is recommended

- Conduct soil testing (pH, EC, organic matter content) before treatment to select appropriate fertilizers based on specific soil problems

- Adapt application rates and methods according to local conditions and crop requirements

Integrating Soil Restoration with Modern Fertilizer Production

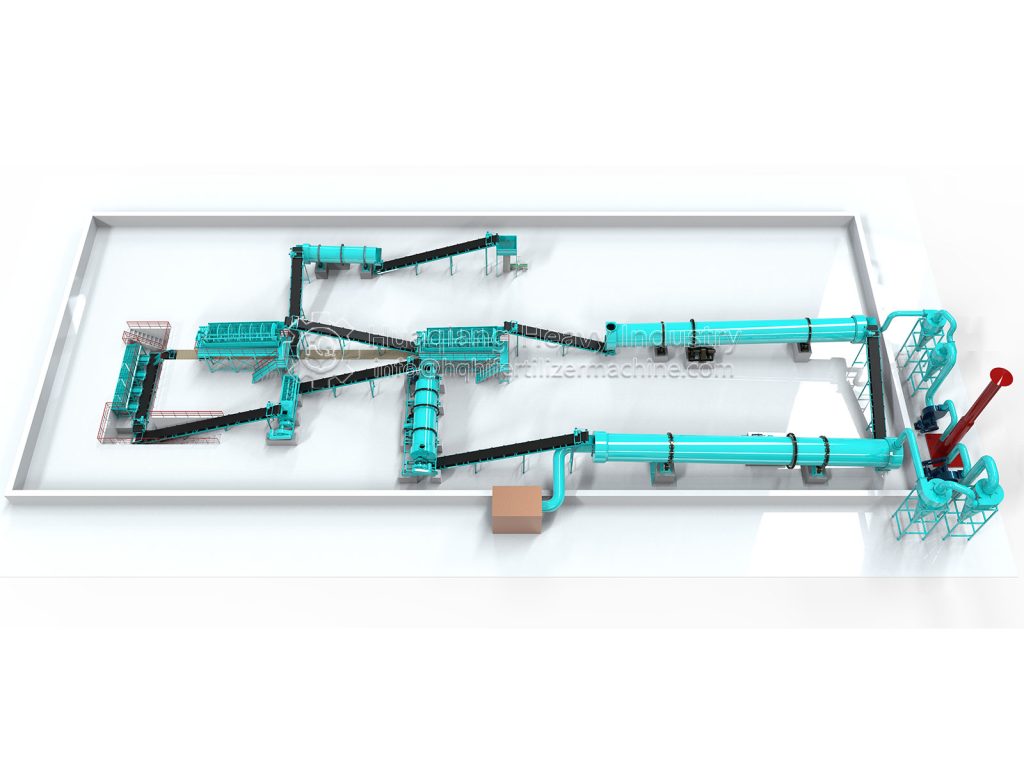

The successful implementation of soil restoration strategies depends heavily on access to high-quality fertilizers produced through advanced manufacturing processes. Modern organic fertilizer production line systems play a crucial role in creating the restoration amendments discussed, transforming raw materials into effective soil conditioners. The organic fertilizer fermentation process, accelerated by equipment like the chain compost turner and large wheel compost turning machine, ensures stable, pathogen-free organic fertilizers essential for rebuilding soil health.

For granular products that facilitate precise application, various fertilizer granulator technologies are employed. The rotary drum granulator and drum granulator excel in drum granulation of organic materials, while the double roller press granulator and fertilizer roller press machine create compacted granules without binders. In parallel, npk fertilizer production line setups support the npk production process to create balanced mineral fertilizers through specialized npk fertilizer granulator equipment.

The complete npk fertilizer manufacturing process integrates multiple technologies to address specific soil deficiencies, while bio organic fertilizer production line configurations combine composting with microbial inoculation. From the wheel compost turner processing raw materials to the double roller granulator forming final products, these interconnected systems provide the technical foundation for manufacturing the restoration fertilizers that combat global soil degradation challenges.

Conclusion

Targeted fertilizer application offers a sustainable approach to soil restoration. By understanding the specific properties and mechanisms of different fertilizers, farmers and land managers can effectively address various soil degradation issues. Regular monitoring and adaptive management are essential for successful, long-term soil health improvement and sustainable agricultural production.