On the stage of modern agriculture, the new type stirring tooth organic fertilizer granulator performs like a master craftsman, transforming powdery raw materials into uniform, spherical fertilizer pellets. The new type of stirring tooth organic fertilizer granulator is also called “new type of two-in-one organic fertilizer granulator“, a title reflecting its dual-function efficiency. While alternatives like the disc granulator anchor a conventional disc granulation production line, this advanced fertilizer granulator offers remarkable versatility. It serves as a core component not just in a dedicated organic fertilizer production line, but can also be integrated into a standard npk fertilizer production line or a complete npk fertilizer line. This seemingly simple machine contains exquisite engineering design, with each component carefully calculated to complete the “raw material metamorphosis” with high efficiency and consistent quality, making it a valuable asset across different fertilizer manufacturing systems.

1. The “Internal Organs” of Granulator

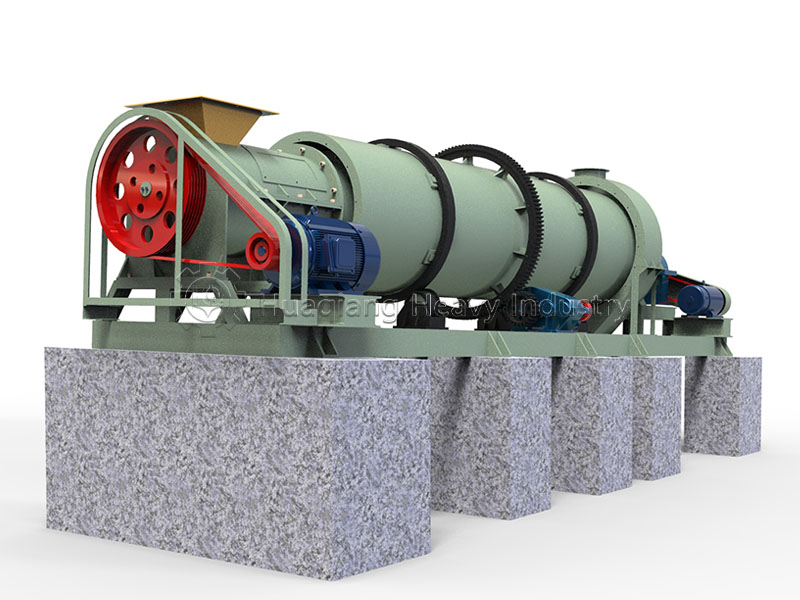

An efficient new type of stirring tooth organic fertilizer granulator is like a precision Swiss watch, with each part performing its own role:

Feeding System – Like the machine’s “mouth,” composed of a hopper and screw feeder. This “smart oral cavity” can precisely control “food intake” according to production needs, ensuring materials enter the granulation cylinder evenly and steadily.

The granulation cylinder is the machine’s “stomach,” made of stainless steel with diameters ranging from 0.5-2 meters and lengths of 1-3 meters. Its smooth inner wall is like a non-stick coating, preventing material adhesion and making the granulation process smoother.

The stirring teeth are the machine’s “teeth,” with 4-8 high-strength alloy steel stirring teeth arranged symmetrically, rotating at 300-1000 rpm, mixing and kneading materials thoroughly like a blender.

Organic Fertilizer Materials

Require fermentation and composting first, crushed to 40-80 mesh, with moisture content controlled in the “golden range” of 20%-30%

Compound Fertilizers

Basic fertilizers like nitrogen, phosphorus, and potassium are mixed in precise proportions, requiring mixing uniformity of over 85%

2. The “Metamorphosis” of Fertilizer Production

From raw materials to finished fertilizer, a gorgeous transformation takes place:

After pre-processed materials enter the granulation cylinder, the water spray device evenly sprays water or binder like spring rain. The high-speed rotation of stirring teeth generates strong centrifugal force, causing materials to gradually agglomerate into 1-5 mm pellets through collisions.

Newly formed pellets must pass through the screening “quality checkpoint,” with unqualified pellets sent back for “reprocessing.” Qualified pellets then enter the drying and cooling stage, with moisture reduced to below 10% and temperature lowered to room temperature, finally dressed in the “clothing” of woven bags or plastic bags, ready to head to the fields.

Interestingly, the entire granulation process is like making meatballs – it requires the right “mince” (raw materials), appropriate “mixing intensity” (rotation speed), and proper “moisture” (binder) to produce uniformly sized “meatballs” (fertilizer pellets).

This seemingly simple machine is actually an important promoter of agricultural modernization. It not only improves fertilizer utilization and reduces resource waste but also saves farmers from the toil of manual fertilization. Next time you see neat, uniform fertilizer pellets, remember the “magician” working silently behind them.