In the precise world of modern fertilizer production, the NPK fertilizer granulator acts as a sophisticated sculptor, transforming loose powdered raw materials into uniform, dense pellets through advanced engineering. This seemingly simple equipment embodies remarkable technical wisdom, employing either the rotary drum granulator or disc granulator technology to achieve optimal fertilizer granules compaction.

The heart of the NPK manufacturing process lies in this precise granulation stage, where specialized fertilizer compaction machine equipment ensures consistent particle size and structural integrity. Within the comprehensive NPK production line, the drum granulator utilizes centrifugal force and liquid binders to create spherical granules, while alternative systems employ pressure-based compaction methods. Each fertilizer production machine is calibrated to maintain the precise NPK ratio throughout the NPK fertilizer manufacturing process, ensuring optimal nutrient delivery and minimal dust formation.

.jpg)

.jpg)

The Art and Science of Granulation

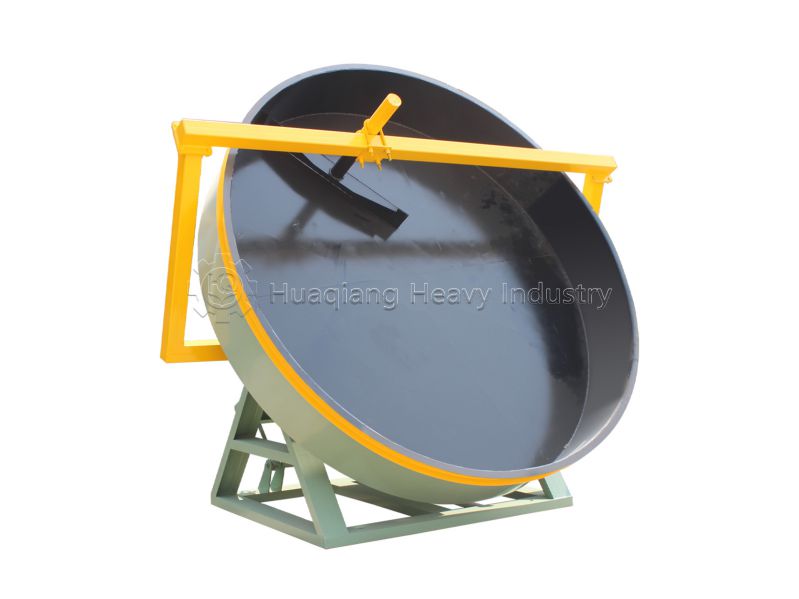

The NPK fertilizer granulator is specialized equipment for processing powdered raw materials into granules, particularly suitable for organic-inorganic compound fertilizers and high nitrogen content products. It’s not just a machine, but a magician of fertilizer transformation, achieving the magnificent metamorphosis from powder to pellets through precise mechanical design.

Imagine that various nutrients are gradually condensed into uniform particles through the ingenious operation of the granulator. This process not only improves the physical properties of the fertilizer, but also significantly increases the utilization rate of the fertilizer, laying a solid foundation for precise fertilization in modern agriculture.

Perfect Harmony of Precision Construction

Sturdy Frame

Constructed with thickened channel steel welding, like the steel skeleton of a building, providing stable support foundation for the entire equipment, ensuring long-term operational stability and reliability.

Drum Design

Drum-type structure welded with thickened steel plates, like a precise rotating stage, providing ideal granulation environment for materials, ensuring uniform pellet formation.

Agitating Teeth Granulation

Innovative agitating teeth granulation mechanism, like dexterous fingers, skillfully kneads powdered materials into ideal pellet forms during rotation.

Internal Drive

Coupling soft connection design, like flexible joints, effectively cushions impact forces, ensures smooth transmission, and extends equipment service life.

External Drive

Cast steel gear mesh transmission system, like precise clockwork mechanism, ensures accurate and efficient power transmission, achieving stable and reliable operation.

Outstanding Technical Advantages

· High Efficiency Granulation – Rapidly converts powder into uniform pellets

· Wide Adaptability – Suitable for various high-nitrogen fertilizer formulations

· Stable Operation – Robust structure ensures long-term stable production

· Energy Saving Design – Optimized transmission system reduces energy consumption

· Easy Maintenance – Modular design simplifies maintenance procedures

· Precise Pellet Control – Adjustable parameters meet different requirements

Innovative Technical Features

The NPK fertilizer granulator integrates multiple advanced technologies, showcasing unique technical charm:

Agitating Teeth Technology | Dual Drive System | Reinforced Structure | Intelligent Control | Eco-friendly Design

From the sturdy frame to the precise transmission system, from innovative granulation mechanisms to intelligent control technology, the NPK fertilizer granulator has become an indispensable key equipment in modern fertilizer production with its excellent engineering design and reliable production performance. It not only changes the physical form of fertilizers but also enhances their practical value, contributing significant technical power to global agricultural production.