Behind the global palm oil industry lies a significant environmental challenge: tens of millions of tons of oil palm empty fruit bunches (EFB) are generated annually. If not managed properly, this agricultural waste can impose a heavy burden on the environment. However, through scientific composting, EFB is being transformed from waste into a valuable resource, and the environmental benefits and resource cycling efficiency of this process can be systematically evaluated through Life Cycle Assessment (LCA).

Environmental Advantages Revealed by Life Cycle Assessment

Life Cycle Assessment is a comprehensive method for evaluating the environmental impacts of a product, process, or service from “cradle to grave.” LCA studies on EFB composting have yielded two core conclusions.

First, EFB composting demonstrates significant advantages in greenhouse gas emission reduction. Traditional EFB disposal methods primarily involve open burning or simple landfilling. Burning directly releases pollutants such as carbon dioxide and sulfur dioxide, exacerbating air pollution and climate change. Landfilling, under anaerobic conditions, generates large amounts of methane, a greenhouse gas with a warming potential over 25 times that of carbon dioxide. In contrast, the aerobic composting process converts organic matter in EFB into stable humus through controlled fermentation, substantially reducing methane emissions. Studies confirm that compared to traditional disposal methods, EFB composting can achieve a net reduction of 15% to 40% in greenhouse gas emissions, representing a more environmentally beneficial waste treatment pathway.

Second, composting greatly enhances resource cycling efficiency. EFB itself is rich in organic matter and potassium, but its high carbon-to-nitrogen ratio limits the efficiency of direct composting. When EFB is converted into organic fertilizer that meets horticultural standards, it forms a closed-loop cycle of “solid waste → organic fertilizer → agricultural application.” This not only addresses the challenge of solid waste disposal but also produces high-value agricultural inputs, enhancing the economic viability and ecological sustainability of this recycling model.

Amendments: The Key to Enhancing Composting Efficiency

However, composting EFB alone faces challenges such as long fermentation periods, low maturity, and limited nutrient diversity. Here, the addition of amendments becomes the key to overcoming these bottlenecks. Amendments optimize the composting process significantly by adjusting the physicochemical properties of the compost materials and accelerating microbial metabolism. Their impact is primarily manifested in three aspects.

Firstly, they significantly shorten the composting cycle. Unamended EFB composting typically requires over 90 days for fermentation and is prone to issues like “anaerobic heaps” due to an imbalanced carbon-to-nitrogen ratio. By adding suitable amendments to adjust the mixture’s C/N ratio to the ideal range of 25-30:1, the composting cycle can be reduced to within 60 days, greatly improving processing efficiency.

Secondly, they effectively optimize product quality. Amendments can supplement the nutrients lacking in EFB, enhancing the fertilizing effect of the final compost. For example, banana skins, rich in readily available nutrients such as phosphorus, potassium, and nitrogen, not only provide quickly utilizable carbon and nitrogen sources for microorganisms but also significantly increase the nutrient content of the final compost product.

Thirdly, they enhance the sterilization effect. Maintaining a temperature above 55°C during the composting process is crucial for killing pathogens and weed seeds. Research shows that an EFB pile amended with 10% banana skins can rapidly heat up to over 45°C by the third day, more easily reaching and maintaining effective sterilization temperatures. In contrast, a pure EFB control group reached a maximum temperature of only 39°C, failing to achieve effective sterilization.

Synergistic Benefits of Banana Skin as an Amendment

A 45-day, 100-kilogram scale experiment vividly demonstrates the potential of banana skins as an amendment. In the experiment, the EFB pile amended with 10% banana skins (H10 group) heated up faster and reached a significantly higher final temperature compared to the pure EFB control group. This proves that banana skins can effectively activate microorganisms and accelerate the decomposition of recalcitrant materials like lignin and cellulose.

More importantly, the use of banana skins, which are themselves common agricultural waste, embodies the synergistic concept of “using waste to treat waste.” It not only improves the efficiency and quality of EFB compost but also concurrently addresses its own disposal problem, offering dual environmental benefits and cost advantages. Experimental results show that the compost product amended with banana skins exhibited a 20% to 30% increase in available nutrient content, making it more suitable as a high-quality horticultural fertilizer or soil conditioner.

In summary, Life Cycle Assessment, from a holistic perspective, confirms the significant potential of EFB composting in mitigating climate change and promoting resource cycling. Amendments, especially low-cost, readily available agricultural by-products like banana skins, are the key catalysts for realizing this potential. By adjusting the composting microenvironment, they effectively address the technical bottlenecks of EFB composting and enhance the economic and environmental value of the product.

Looking ahead, further exploration of optimal mixing ratios between EFB and different amendments (such as livestock manure, biochar, etc.) will help maximize composting efficiency and benefits. In the global push for a circular economy and sustainable agriculture, transforming agricultural wastes like EFB into “black gold” is not only a technological innovation but also a solid step toward a resource-efficient and environmentally friendly society.

Conclusion & Path Forward

In conclusion, the transformation of Empty Fruit Bunches (EFB) through composting represents a vital model of circular bioeconomy in the palm oil sector. The integration of effective amendments, as validated by LCA, not only accelerates the organic fertilizer fermentation process but also elevates the final product’s quality, turning a major waste stream into a valuable agricultural input.

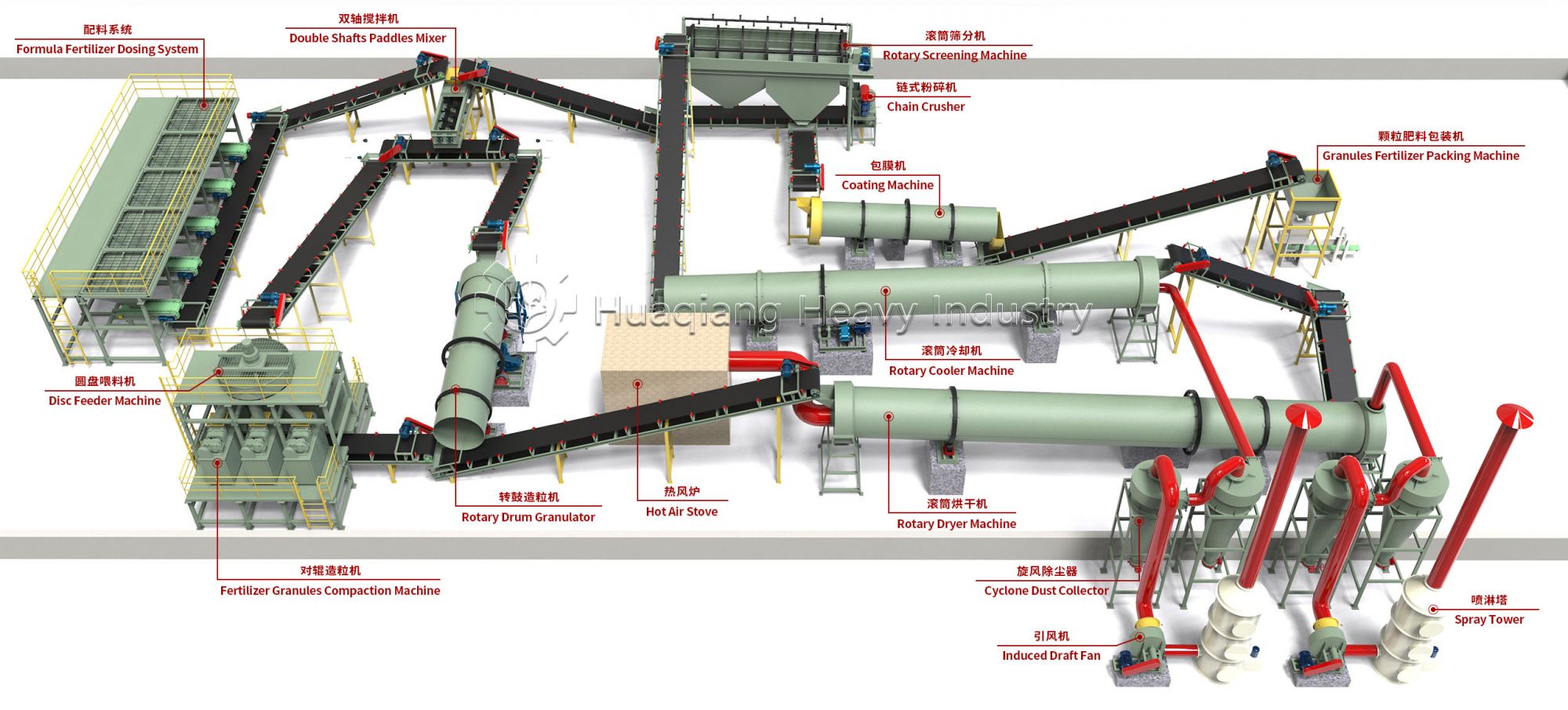

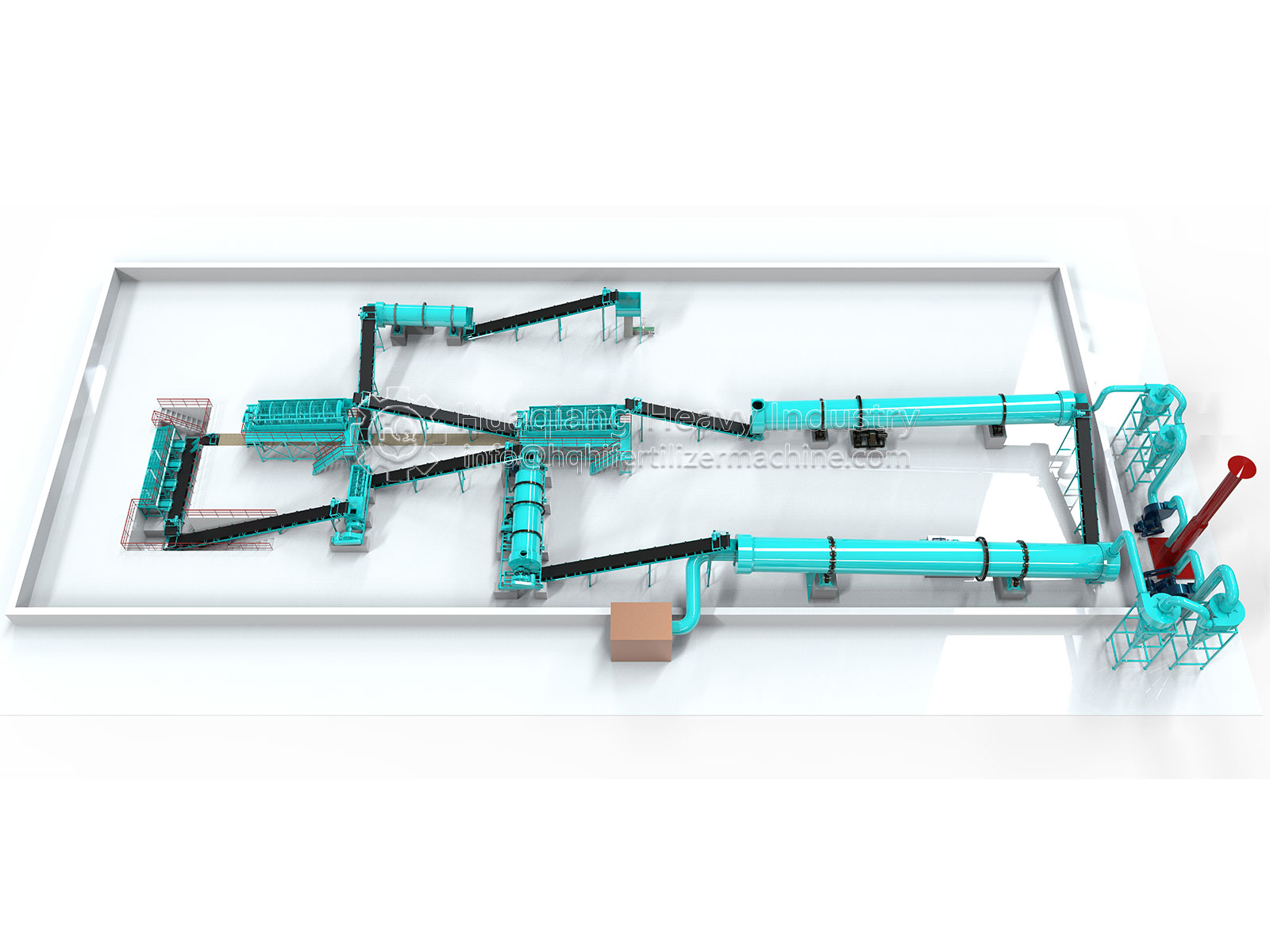

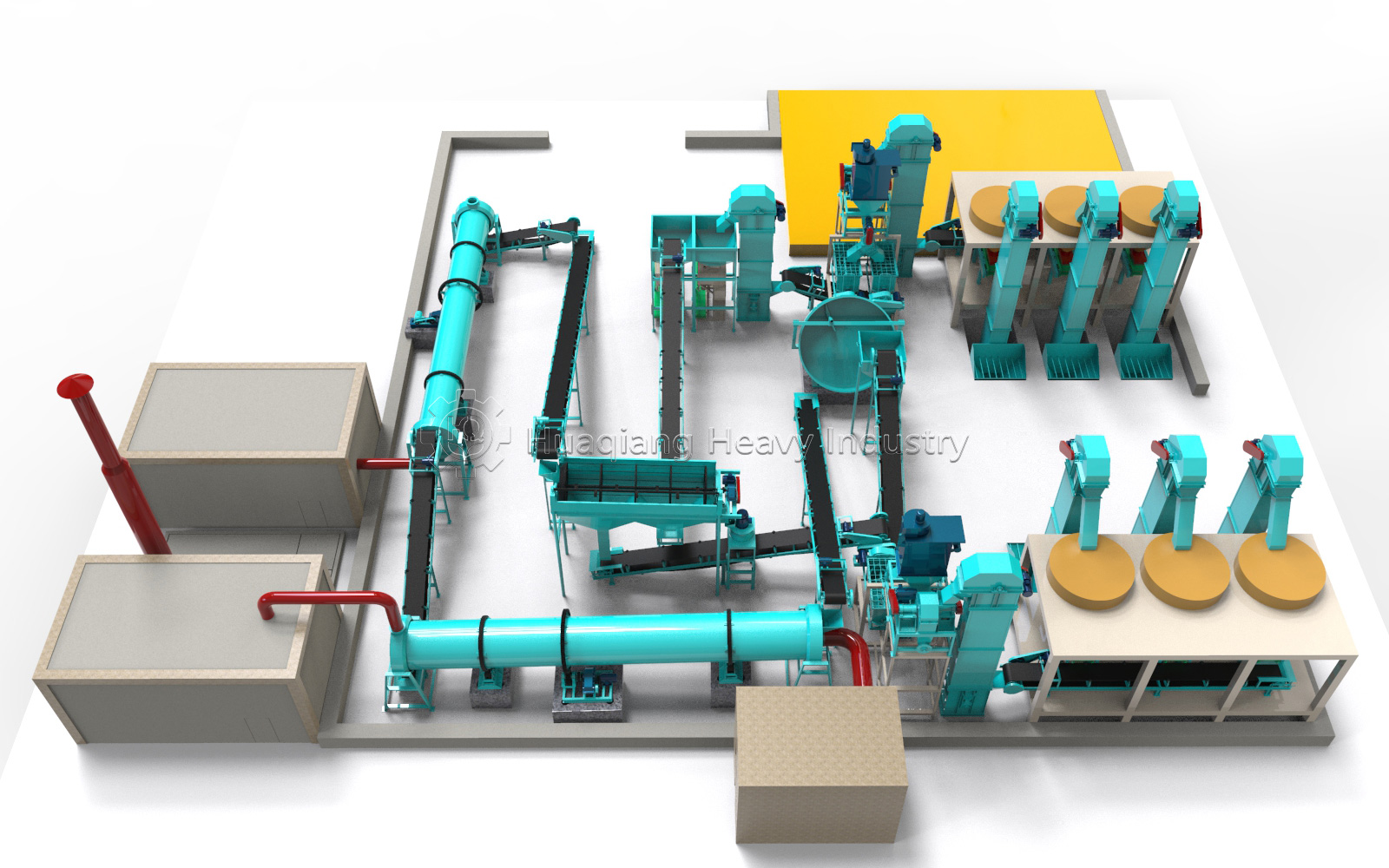

To scale this sustainable practice, efficient fermentation composting turning technology is essential. Equipment such as a chain compost turning machine or large wheel compost turning machine ensures optimal aeration and temperature control during the composting phase. Subsequently, the matured compost can be processed through a complete organic fertilizer production line, where an organic fertilizer granulator—like the innovative new type two in one organic fertilizer granulator—shapes the material into uniform, market-ready pellets. This integrated approach, from windrow turning to granulation, forms the core of a modern bio organic fertilizer production line, closing the loop from agricultural waste to sustainable soil amendment.

Thus, by pairing smart biological amendments with advanced processing technologies, EFB composting evolves from a waste management solution into a pillar of regenerative agriculture, contributing to both environmental resilience and farm productivity.

Integrated Technical System: organic fertilizer production line, organic fertilizer fermentation, fermentation composting turning technology, new type two in one organic fertilizer granulator, chain compost turning machine, large wheel compost turning machine, bio organic fertilizer production line, organic fertilizer granulator.